Amashubhu agcwalisa umshini we-laminate yepulasitiki le-aluminium (kufika ku-320 ppm)

Incazelo emfushane yomshini wokugcwalisa wejubane eliphezulu

1. I-servo kagesi ye-High Speed Tube Fill Machine ingashintsha ijubane ngawodwana, ijubane lokukhiqiza lomshini we-tube filler lingalungiswa.

2,Ijubane eliphakeme lokugcwalisa umshini wokugcwalisa umshini ngejubane eliphezulu le-320 Tube Ukugcwaliswa ngemizuzu.Ijubane elivame kakhulu licishe libe yi-280 tube ukugcwaliswa ngomzuzu

2. Idivayisi yejagi isebenza ngejubane eliphansi ukuze isebenze kalula

3. Iphaneli enkulu (HMI) ukulungisa zonke izilungiselelo zobubanzi zokucubungula

4. Iphaneli yokusebenza ikhombise ubungako bokukhiqiza kanye nesimo somugqa wokukhiqiza ukuze kuqashelwe

I-5

6 .. I-High Speed Tube Ukugcwalisa Umshini Wokulawula Iphaneli Ungasetha Imisebenzi yepharamitha

7.. Umshini wokugcwalisa we-Tube ezenzakalelayo unephaneli yokusebenza evikelwe ngamazinga wokusebenza ahlukene ama-3 wokuphathwa kweziphathimandla

8 .. Ijubane eliphakeme lokugcwalisa ishubhu lokugcwalisa iKhabhinethi engenasisekelo yensimbi ezimele ngogesi ezingenasici ngesimo somoya, izinga lokuvikela lifinyelela ku-IP65 noma ngaphezulu. Amakhabe we-Cable we-Tube Filler phakathi kwamakhabethe kagesi nemishini sebenzisa amathreyi e-CEbed avaliwe, izintambo zivela phezulu komshini osezingeni eliphakeme.

Ngokuzayo, uhlelo lokulawula lwe-High Speed Tube Fill Machine lungasebenzisa i-Nokia Profing Machine ukudlulisa idatha ku-MES futhi Xhuma nohlelo lwe-MES.

Ijubane eliphakeme le-thubhu yokugcwalisa umshini wepulasitiki le-laminate ne-aluminium tube

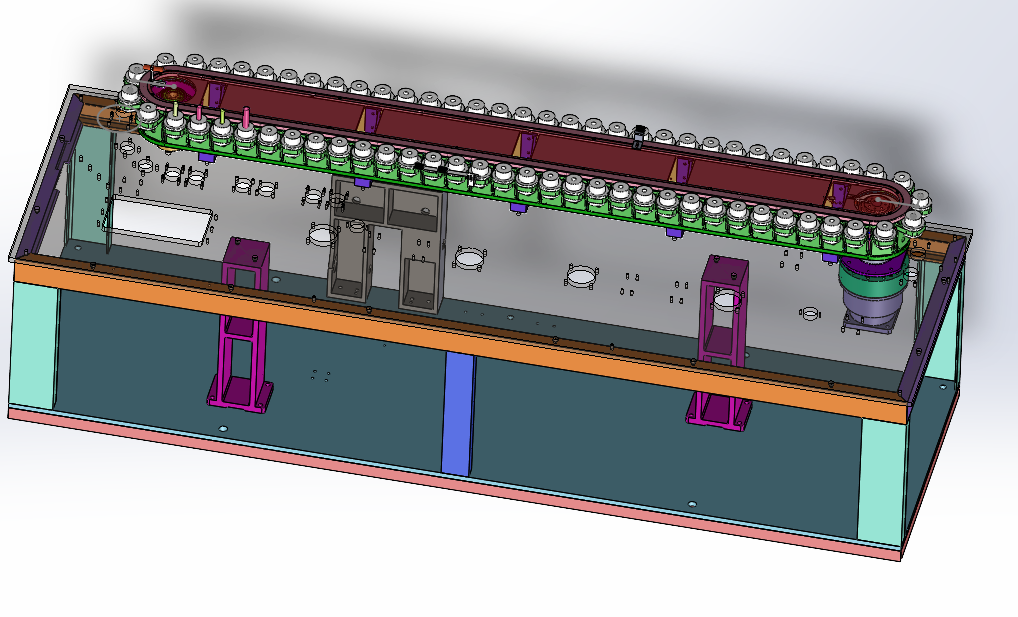

I-LFC4002 Speed Speed Tube Wokugcwalisa Umshini ukugcwaliswa kwesiteshi esitemvane kanye nokufaka uphawu kwe-tube. Kuthuthukiswe i-Full-Servo Plastic Bust Machine ngokuzimela, eyenzelwe futhi kwakhiqizwa nge-Tube ye-Tube ye-Aluminile ngayinye, i-Aluminium Tubes Ukugcwalisa Inqubo, ijubane le-Aluminium Tubes, isivinini sokwakha amashubhu / umkhawulo wangempela Ijubane lokukhiqizwa elijwayelekile le-tube ye-filler lingamashubhu / imizuzu engama-250-340. Ukugcwalisa ukunemba kungu- ≤ ± 0.5%. Ingxenye ye-aluminium tube mechanical ivalwe ngokugoqa ukubekwa uphawu, i-aluminium-plastic composite tube ivalwe ngokomoya okushisayo noma ubuchwepheshe obukhulu bokushisa

Ijubane eliphakeme le-Tube Ukugcwalisa Umshini Wokuhambisa Okukhulu:

Umshini wokugcwalisa wejubane eliphezulu I-Adopt Anloy Steel Guide Rail, i-anti-vibration tube cap holder yokuvala umshini, iqoqo le-4KW servo ye-tube i-Cube Cunuve Chain Mechanism. Lo mshini wejubane eliphezulu unquma isivinini esikhulu esiphezulu @ 320 Tube Ukugcwaliswa ngemizuzu nokuqina kokugcwaliswa kweshubhu lepulasitiki nokupakishwa kokubopha uphawu

Ijubane eliphakeme le-Tube Fill Fill Machine Tube Cup Cup Chain Chain Chain Idivaysi iqukethe ujantshi wesiqondisi esiphezulu esiphezulu, esiphansi kanye neseceleni. Kufakwe amabhele amathathu okugoqa esihlalweni senkomishi yeshubhu, futhi ama-rollings ahamba ngokuqondile emiseleni futhi aqhube amashubhu. Ukugcwalisa umshini chain akunankinga isikhathi eside ukugijima. Kukhona futhi izinatisi ezimbili eziphakeme eziphakeme futhi eziphansi ze-roller ezibekwe ezihlotsheni zokujikeleza kosayizi weshubhu.

Umshini wokugcwalisa wejubane eliphezulu, i-tube ehambisa ugenge uvale futhi ilungise izihlalo zeshubhu (ukuma okuthe tube, usimukeli wensimbi) komunye nomunye ibhande lokuhambisa. Ibhande elihlanganisiwe le-Tube lokugcwaliswa komshini wokugcwalisa ishubhu lisebenza ngokuqinile ngokuya nge-trajectory yokuhambisa isondo lokushayela. I-Tube Cup ifakwe kwindandatho ngayinye yeshubhu. Umshini wokugcwalisa unezindebe eziyi-116 zenza umshini oqinisekise ukuthi ungagijima ngejubane eliphezulu u-320 Tube / amaminithi we-tube inkomishi eyenziwe ngezinto eziphakeme ze-pom nezidingo zokuklama.

I-High Speed Tube Fill Machine Machine I-Chain i-Shorts i-Overload itholwa ngokunemba okutholwe ngokuqondile kwe-torque ye-torque efakwe kwisondo lokuhambisa, elinempilo yenkonzo ende. Uma i-change ye-tube inamathele, i-clutch inqanyuliwe, ukushintshwa kokusondela kudalwa, futhi umshini uyeka ngokushesha ngisho nasesimweni esisheshayo esisebenza ngejubane eliphezulu

Ijubane eliphakeme le-Tube Ukugcwalisa Inqubo Yokuhlanza Inqubo Yokuhlanza Inqubo

1

2. Ngaphambi kokuqala i-CIP ye-High Speed Tube Fill Machine, kufakwe i-nozzy yokugcwalisa ye-tube ye-Cube, i-Clearing Liquid izokhishwa kusuka emshinini we-tube uphawu ngepayipi exhunywe kwi-CIP Dummy Cup.

I-3. I-CIP Workstation (enikezwe ikhasimende) ihlinzeka nge-ejenti yokuhlanza ekungeneni kwe-hopper ye-hopper ye-high tur tube ukugcwalisa ishubhu. Ibhola lokufafaza lifakwa kwisilinda, bese i-Spray Ball ifaka i-ejenti yokuhlanza ebusweni bangaphakathi kwesilinda. Uhlelo lokugcwaliswa komshini we-tube uphawu lwepulasitiki lwenzelwe ngokwezinqubo zokuhlanzeka, futhi uketshezi lokuhlanza lwe-CIP lungafinyelela zonke izikhala zejubane eliphakeme le-tube yokugcwalisa, amapayipi nezinsimbi ezithinta umkhiqizo wepulasitiki wokuvalwa uphawu kwepulasitiki. Izingxenye ezinyakazayo zomshini we-tube fleller ohlangana nomkhiqizo ngesikhathi senqubo yokukhiqiza, njengamaphampu wePiston, ama-agagitators, nawo azoshintsha ngokufanele ngesikhathi sokuhlanza i-CIP ukuze aqinisekise ukuthi zonke izingxenye zezingxenye ezihambayo zingahlanzwa ngokuphelele.

I-4. Ipayipi elixhumayo loketshezi lokuhlanza ukuze ubuyele ohlelweni lwe-CIP lwekhasimende lwe-Hip Speed Tube Wokugcwalisa (impompo yokubuyisa ayifakiwe kububanzi bokunikezwa)

I-5

6 Ukushisa, ingcindezi, izinga lokugeleza nesikhathi somjikelezo we-CIP kungasetwa yisiteshi se-CIP ngokuya ngezidingo zamakhasimende.

7

I-8.CIP Traic idinga ukuthi umshini wokugcwalisa wejubane eliphakeme nge-2t / h noma ngaphezulu

Ijubane eliphakeme le-Tube Ukugcwalisa umshini ukwamukela amarobhothi ukuyondla amashubhu (15x2 amashubhu athathwe ngemigqa ephindwe kabili isikhathi ngasinye, izikhathi eziyi-9-12 / Minute):

Ngokusho kohlelo oluhleliwe, umshini wokugcwalisa wejubane oluphezulu une-robot akhipha imigqa emibili yamashubhu ebhokisini le-tube elinqunyelwe isikhathi ngasikhathi sinye, bese lifaka zibheke phezulu kwi-Tube Cup inhloso yejubane, bese ifaka insimbi yokuxhaswa kweshubhu, futhi isebenzisa insimbi engagqwali ukuze iqinise iminwe. kungahlukaniswa ngokuhlanza kanye nokubulala amagciwane noma amagciwane nge-hydrogen peroxide spray lapho i-high speed tube filler iyekile

I-grating ithola ukuthi ngabe kukhona i-tubeleft emnweni werobhothi ongafakwanga kwinkomishi ye-tube, futhi wenza umshini wokukhushulwa ukuze ususe ishubhu kusuka umunwe, bese uqhubeka nokuthatha ishubhu.

Umshini wokugcwalisa we-LFC4002 High Speed Tube unezindlela ezilandelayo:

a. Uhlelo lokulawula: Ijubane eliphakeme le-Tube Fill Machine amukela isikrini se-Nokia Thinta nesilawuli se-ukhiye waseJapan, i-servo ukhiye we-servo; Umsindo ungaphansi kwama-decibels angama-75.

b. I-Indexing Mechanism: Umshini wokugcwalisa usebenzisa uhlelo lwe-servo njengenkomba yomshini ophakeme run run @ 320 Tube nge-tube yokugcwaliswa kanye nokufaka uphawu lomshini wokugcwaliswa kwepulasitiki ngaphezulu kwejubane 260pcs

c. I-Cup Chain Guide Rail: Umshini wokugcwalisa we-Tube othomathikhi wamukela ukusebenza kwesiteshi esine-CEATIng ngezindlela ezine zokugcwalisa isivinini, i-anti-vibration tube dup holder mechanism lapho umshini usebenza ngejubane elikhulu

d. Ukuhlukaniswa kwezindawo: Ukugcwaliswa kwe-Plastic Tube nokufaka uphawu kwe-tube kunesithunzi sokuzihlanza, ukulayishwa komshini we-robot

e. Ukuma kwebhokisi le-Tube: Umshini wokugcwalisa okuzenzakalelayo we-Tube wamukela izinto zokuhamba ezinobuqili. Ibhokisi le-tube lihanjiswa engxenyeni engenhla, ibekwe endaweni ethambekele endaweni ethambekele, bese kuthi ibhokisi elingenalutho libuyiselwa engxenyeni engezansi.

f. Indlela yokulayisha ishubhu: Umshini wokulayisha irobhothi noma ishubhu ungene amashubhu, futhi ungagcina amashubhu angama-3000-4000 isikhathi ngasinye.

H. Ukufakwa uphawu kwe-servo

Mina. Ukugcwaliswa kwe-servo

J. I-Aluminium Tube Clamping futhi i-Flattening: Ukuqubuka kanye ne-Flattening Mechanism yedivaysi yokuvalwa kwemsila kwasekuqaleni kwaqala ukubhoboza isiketi, esingacindezela kalula umoya ku-tube. Ishintshelwe ku-clamping evundlile kanye nendlela evundlile, ebingenalo uthuli futhi igwema ukushayela igesi ku-tube.

k. I-Aluminium Tube umsila uphawu Lokhu kulungele ikakhulukazi imisila emithathu.

n. Idivayisi yokukhipha: I-servo ekhipha ishubhu elinamamitha amane futhi linomsebenzi owenqabile.

o. Ukudlulisela okuvumelanayo: ukunyakaza kwe-servo ngezikhathi ezithile, ukudlulisela phambili umkhombe okuhlukile, ukuvumelanisa okuhle.

p. I-Pressure Hopper: I-Adova indlela evulwa ngokushesha yepayipi lokusabalalisa ukuxhuma kwipompo yokugcwalisa.

Q. I-CIP eku-inthanethi: Ingahlanzwa online noma ungaxhunyiwe ku-inthanethi.

Ipharamitha yezobuchwepheshe

- Amashubhu agcwalisa umshini wemishini yemishini yezobuchwepheshe mabhuku

| No | ipharameter | kuphawula | |

| I-Tube Procation (MM) | Ububanzi 13 ~ 30, ubude 60 ~ 250 |

| |

| Umbala umaki wokuma (mm) | ± ± 1.0 |

| |

| Ukugcwalisa umthamo (ml) | 1.5 ~ 200 (Hlangana nezincazelo ze-5G-50G, ukucaciswa okuthile nosayizi ngokuya ngezinhlobonhlobo nobuchwepheshe) |

| |

| Ukugcwalisa ukunemba (%) | ≤ ± 0.5 |

| |

| Imisila yokuvala uphawu | Ama-fold-folds amabili, ama-soddles amathathu, futhi ama-saddle-shape atholakalayo. |

| |

| Umthamo wokuphuma | 250-300 ishubhu ngomzuzu |

| |

| Ishubhu elifanele | I-Aluminium Pekale Pise Aluminium Plastic Pip |

| |

| Ukusetshenziswa kwamandla (KW) | I-Tube ye-filler | 35 |

|

| Ilobhothi | 10 |

| |

| Ubuqhwaga | 380v 50hz |

| |

| umfutho womoya | 0.6MPA |

| |

| Ukusetshenziswa komoya (m3/ h) | 20 ~ 30 |

| |

| Ifomu Lokuhambisa | (Kungeniswa kusuka ku-Italy) I-Synchronous Belschronous Belt Type (Servo drive) |

| |

| Indlela Yokuhambisa | I-Servo drive ephelele |

| |

| usayizi (mm) | Ubude obungu-3700 ububanzi 2000 Height 2500 |

| |

| Isisindo esiphelele (kg) | 4500 | ||

I-Smart Zhitong inabaqambi abaningi abaqeqeshiwe, abangaklamaUmshini wokugcwalisa amashubhungokuya ngezidingo zangempela zamakhasimende

Sicela uxhumane nathi ngosizo lwamahhala @whatspp +86I-15800211936

Ukugcwalisa kanye nokufaka uphawu kwenqubo yokwenza ngokwezifiso

1. Ukuhlaziywa kwesidingo: (ama-URS) Okokuqala, umhlinzeki wesevisi ngokwezifiso uzoba nokuxhumana okujulile nekhasimende ukuqonda izidingo zokukhiqiza amakhasimende, izici zomkhiqizo, izidingo zokukhipha kanye neminye imininingwane ebalulekile. Ngokuhlaziywa kwesidingo, qiniseka ukuthi umshini owenziwe ngezifiso ungahlangabezana nezidingo zangempela zamakhasimende.

2 Uhlelo lokuklama luzofaka ukwakheka kwesakhiwo somshini, ukwakhiwa kohlelo lokulawula, ukwakheka kwenqubo, njll.

3. Ukukhiqizwa okwenziwe ngokwezifiso: Ngemuva kokuthi uhlelo lokuklama luqinisekiswe yikhasimende, umhlinzeki wesevisi ngokwezifiso uzoqala umsebenzi wokukhiqiza. Bazosebenzisa izinto ezisezingeni eliphakeme ezifuywayo nezingxenye ngokuya ngezidingo zohlelo lokuklama ukukhiqiza ukugcwalisa kanye nemishini yokufaka uphawu ehlangabezana nezidingo zamakhasimende.

4. Ukufakwa kanye nokulungisa iphutha: Ngemuva kokuthi ukukhiqizwa sekuqediwe, umhlinzeki wesevisi ngokwezifiso uzothumela ochwepheshe abaqeqeshiwe kwisiza seKhasimende sokufakwa kanye nokulungisa iphutha. Ngesikhathi sokufakwa nenqubo yokuqashwa, ochwepheshe kuzokwenza ukuhlola okuphelele nokuhlolwa emshinini ukuze kuqinisekiswe ukuthi kungasebenza ngokujwayelekile futhi kuhlangane nezidingo zokukhiqiza amakhasimende. Nikeza ngezinsizakalo zamafutha neze-SAT

I-5. Izinsizakalo Zokuqeqesha: Ukuze uqinisekise ukuthi amakhasimende angasebenzisa umshini wokugcwalisa nokubopha kahle ngobuhlakani, abahlinzeki bethu bezinsizakalo ezenziwe ngezifiso nabo bazohlinzeka ngezinsizakalo zokuqeqesha (njengokukhipha iphutha efektri). Okuqukethwe kokuqeqeshwa kufaka izindlela zokusebenza zomshini, izindlela zokulungisa, izindlela zokuxazulula izinkinga, njll. Ngokuqeqeshwa, amakhasimende angakwazi kangcono kahle amakhono okusebenzisa umshini futhi athuthukise ukusebenza kahle kokukhiqiza).

I-6. Ngemuva kwenkonzo yokuthengisa: Umhlinzeki wethu wesevisi eyenziwe ngokwezifiso naye uzohlinzeka ngensizakalo ebanzi yokuthengisa ngemuva kokuthengisa. Uma amakhasimende ahlangabezana nanoma yiziphi izinkinga noma adinga ukwesekwa kwezobuchwepheshe ngesikhathi sokusebenzisa, angaxhumana nomhlinzeki wesevisi owenziwe ngokwezifiso nganoma yisiphi isikhathi ukuthola usizo nesikhathi.

Indlela Yokuthumela: Nge-Cargo kanye nomoya

Isikhathi Sokulethwa: Izinsuku zokusebenza ezingama-30

Umshini wokugcwalisa we-1.Tube @ 360PCS / Minute:2. I-TUBE FELLING Machine @ 280cs / Minute:3. I-TUBE FELLING Machine @ 200cs / MinuteUmshini wokugcwalisa we-4.Tube wokugcwalisa @ 180cs / Minute:I-5. I-TUBE FELLING Machine @ 150cs / Minute:I-67. I-TUBE FELLING Machine @ 80cs / Minute8

Q 1.Yini impahla yakho yeshubhu (ipulasitiki, i-aluminium, ishubhu elihlanganisiwe. I-Abb Tube)

Impendulo, impahla ye-tube izodala i-bambang Tube Tailes indlela yomshini we-tube filler, sinikeza ukufudumeza kwangaphakathi, ukufudumeza kwangaphandle, imvamisa ephezulu, izindlela ze-ultrasonic kanye nezindlela zokushisa umsila

Q2, yini i-tube yakho igcwalisa umthamo nokunemba

Impendulo: Isidingo Sokugcwalisa Amandla we-TUBE sizohola ukucushwa kwesistimu yomshini

Q3, uyini umthamo wakho wokuphuma

Impendulo: Ufuna izingcezu ezingaki ngehora. Kuzohola ukuthi mangaki ama-nozzles agcwalisa, sinikeza ama-nozzles amabili amathathu amathathu okugcwalisa amakhasimende ethu futhi okuphumayo kungafinyelela ama-PC / umzuzu angama-360

Q4, yini ukugcwaliswa okubonakalayo okunamandla okushukumisayo?

Impendulo: Ukugcwaliswa okunamandla okugcwaliswa kwayo kuzoholela ekukhetheni kohlelo lokugcwalisa, sinikezela njengokugcwalisa uhlelo lwe-servo, uhlelo oluphezulu lwe-pneumatic dosing

Q5, liyini lokushisa lokugcwalisa

Impendulo: Ukugcwaliswa komehluko kuzodinga umehluko we-hopper (njengeJacket Hopper, Mixer, Isistimu Yokulawula Ukushisa, Isikhundla Sokucindezela Komoya nokunye)

Q6: Yikuphi ukwakheka kokubekwa uphawu

Impendulo: Sinikeza ukwakheka komsila okhethekile, amajamo ajwayelekile we-3D wokuvalwa kwawo komsila

Q7: Ngabe umshini udinga uhlelo oluhlanzekile lwe-CIP

Impendulo: Uhlelo lokuhlanza lwe-CIP ikakhulukazi luqukethe amathangi e-acid, amathangi e-alkali, amathangi amanzi kanye nama-acid amathangi, amaphampu we-acidrali, ama-acid choptors, ama-acid okuhlushwa ama-alkali kanye ne-alkali yokulawula isikrini.

Uhlelo oluhlanzekile lwe-CIP luzokwakha ukutshalwa kwemali okwengeziwe, lusebenza main cishe cishe konke ukudla, isiphuzo kanye namafektri emithi wezokwelapha i-filler yethu

Imikhakha Imikhakha

-

I-mail

-

Ifoni

-

Isihloko

0086 15800211936

0086 15800211936