Umshini wokugcwalisa we-Cream Tube ungomunye we-future ngokugcwalisa ngokuphelele lenkambu ye-cosmetic field, ngoba isebenza kahle kakhulu, futhi ngesikhathi esifanayo seTube seaning kanye nenqubo yokusika. Kunezimo eziningi emsileni we-tube ukuze uhlangabezane kahle nezidingo zamaqembu ahlukene weminyaka emakethe

Umshini wokugcwalisa ukhilimu uvame ukuba nesivinini esiphezulu sokukhiqiza, futhi kunesivinini esihlukile semishini yokugcwalisa yeshubhu emakethe ukuze zihlangabezane nezinhloso zokukhetha zabakhiqizi abahlukene ukhilimu. Ingaqedela ukugcwaliswa ngokushesha ku-tube, ukubekwa uphawu nokusika kwe-Tube Tails yenqubo yama-okhilimu, ama-oyela, ama-gels neminye imikhiqizo.

Umshini uthuthukisa ukusebenza kahle kwenqubo yokukhiqiza ephelele. Umthengisi weTube angahle avumelane ngokushesha ukuze ahlangabezane nezidingo zokugcwalisa zemikhiqizo enokucaciswa kwamashubhu ahlukile nezinhlobo. Ikwamukela ubuchwepheshe obuthuthukisiwe bokugcwalisa ubuchwepheshe be-servo futhi ibona ngokugcwele inqubo yokugcwalisa metering enengqondo yohlelo lokulawula ukuqinisekisa ukuthi umkhiqizo ngamunye uhlangabezana ne-heather ye-sweister ebekiwe noma i-heathen ethe xaxa yaseJalimane ephezulu yokufudumeza imisila yeshubhu. Ukuze wenze umkhiqizo ube muhle ngokwengeziwe. Isimo somsila esihlukile seshubhu sisetshenziselwa ukufeza izidingo zamaqembu ahlukile esibulalayo ezimakethe ezahlukene.

I-angle ye-angle yesokudla ye-angle yokuvalwa uphawu. Ama-engeli angakwesokudla

I-Seaning Tubeam Tail iyona esetshenziswa kakhulu ye-tube lulabulayo yeTube ngamashubhu wezimonyo emakethe. Kuyathandwa ngeningi lama-terminals. Umshini wokugcwalisa i-Tube usebenzisa i-malipulator ekwandiseni komshini wokugcwalisa nokubopha ukufudumeza umsila weshubhu kuzinzwa okucacisiwe. Umshini ugijimela esiteshini esilandelayo sokusika, futhi ususa umsila owengeziwe ngesenzo somshini ukuze wakhe isimo se-angle esifanele. Kule nqubo, umshini uzosebenzisa ubuchwepheshe bokushisa ukuze ufake izinhlangothi zombili zomlomo weshubhu ndawonye ngaphansi kwengcindezi ephezulu, bese unquma imisila yeshubhu ngokweqile kanye nezinto zokweqile ukuze uqinisekise ukuthi uphawu luqinile futhi luhle.

Ubuchwepheshe bokubopha uphawu kwesokudla busetshenziswa kabanzi ekuphaketheni kwemithi, ukudla, kanye nemikhiqizo yamakhemikhali yansuku zonke. Imikhiqizo yalezi zimboni imvamisa idinga ukunemba okuphezulu nokugcwaliswa okuphezulu okusebenzayo kanye nezinqubo zokubopha ukuqinisekisa ikhwalithi yomkhiqizo nokuphepha. Ngasikhathi sinye, ukubekwa uphawu kwesokudla kwesokudla nakho kuhlangabezana nezidingo zalezi zimboni zokubukeka komkhiqizo nokupakisha.

Ukwakhiwa kwamakhompiyutha okuyindilinga we-baving tube kugwema amakhona abukhali omsila weTube wokubopha, ngaleyo ndlela kukhiqize izikhala zokubopha ukubekwa kwesikhashana, ukunciphisa ngempumelelo ingozi yokusika ukuthi abaqhubi bangase bahlupheke lapho besebenzisa noma bephatha umkhiqizo. Ngasikhathi sinye, kuvikela futhi amakhasimende okugcina, ikakhulukazi izingane, kusukela engcupheni yokusikeka lapho usebenzisa imikhiqizo ye-tube. Amakhona ayindilinga enza umsila we-hose ebushelelezi futhi ube nomunyu, uthuthukise umphumela wokubuka ophelele kanye nokuthungwa komkhiqizo. Idizayini ekhoneni eliyindilinga isiza ukunciphisa ingozi yomonakalo kwi-hose ngesikhathi sokugcina nokuhamba, futhi isiza ukuthuthukisa ukusebenza kokubekwa uphawu komkhiqizo.

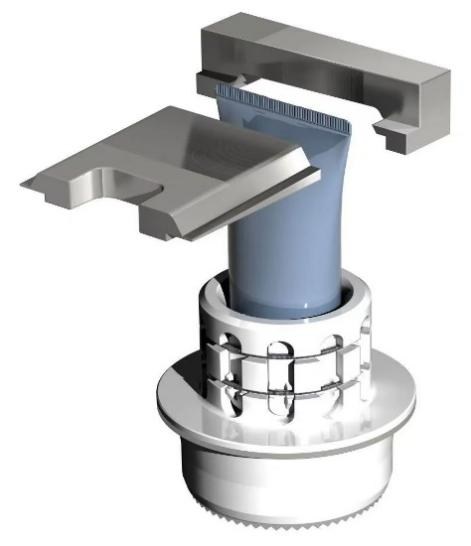

Umshini wokugcwalisa okuzenzakalelayo we-Tube othomathikhi uvame ukuhlonyiswa amakona akhethekile ayindilinga ukubhoboza isikhunta, okubandakanya i-punch nokufa okufana punch ukufeza ama-punch ama-punch. Umsiki unikezwa ePunch, futhi i-punching blade ifaka isigaba esiqondile nezingxenye ze-arc ezinhlangothini zombili. Onqenqemeni lokufa ofayo uqondanisa ukwakheka kwe-punching blade. Njengoba umsiki wokubumba angakwazi ukugqoka ngemuva kokusetshenziswa kwesikhathi eside, okubangela indawo yokusika ukuba ibe yinkimbinkimbi, kuyathinta ikhwalithi ye-punching ekhoneni eliseduze, kuyadingeka ukubheka ukugqokwa kwethuluzi bese kudingeka ukuqinisekisa ikhwalithi yokubukeka komjikelezo Ikhwalithi yezinto ezibonakalayo, ubukhulu nokuqongelela ishubhu kuzothinta nekhwalithi yokubhoboza ekhoneni eliyindilinga. Ngakho-ke, opharetha kudingeka aphathe kahle lokho okuqukethwe, njengokufaka esikhundleni sezinto ezibonakalayo ngensimbi engcono yensimbi, futhi ubunzima kumele bushiswe ukushisa kwe-vacuum baphathwe ukuze bafinyelele ama-degree angama-52 ukwelula impilo e-52.

Ukugcwaliswa kwepulasitiki yepulasitiki nokufaka uphawu kwe-tech parameter

| Model no | Nf-60 (ab) | Nf-80 (ab) | Gf-120 | Lfc4002 | |

| Indlela yokunciphisa umsila | Ukushisa kwangaphakathi | Ukushisa kwangaphakathi noma ukushisa okuthe xaxa | |||

| Izinto ze-Tube | Ipulasitiki, amashubhu we-aluminium .compasite abl lamiminate tubes | ||||

| Ijubane lokuklama (ukugcwaliswa kweshubhu ngomzuzu) | 60 | 80 | I-120 | I-280 | |

| Imithambo ye-Tube Holder | 9 | 12 | 36 | I-116 | |

| I-Tube Dia (mm) | φ13-φ5 | ||||

| I-Tube inweba (mm) | 50-210 Ukulungiswa | ||||

| Umkhiqizo ofanele wokugcwalisa | I-Viscosity yamazinyo 100,000 - 200,000 (CP) amandla athile adonsela phansi ngokuvamile aphakathi kuka-1.0 - 1.5 | ||||

| Ukugcwalisa umthamo (mm) | I-5-250ml iyakwazi ukuguqulwa | ||||

| Umthamo weshubhu | A: 6-60ml, B: 10-120ml, C: 25-250ml, D: 50-500ml (ikhasimende elenziwe latholakala) | ||||

| Ukugcwalisa ukunemba | ≤ ± 1% | ||||

| I-Hopper Ikhono: | 40limi | 55Nightre | 50limi | I-70Litre | |

| Ukucaciswa komoya | I-0.55-0.65MPA 50 M3 / Min | ||||

| Ukushisa Amandla | 3Kw | I-6kw | I-12kw | ||

| Ubukhulu (lxwxh mm) | 2620 × 1220 × 1980 | 2720 × 1020 × 1980 | 3500x1200x1980 | I-4500x1200x1980 | |

| Isisindo se-net (kg) | 800 | 1300 | 2500 | 4500 | |

Ukubekwa uphawu kwesiyingi se-Semi-Circular Ukubekwa uphawu okuyindilinga kwe-tube flealer kanye ne-sealer kuyindlela yokufaka uphawu yokugcwaliswa nokubopha uphawu. Kusho ukuthi ngemuva kokugcwaliswa kokugcwaliswa kweshubhu lepulasitiki kanye nomshini wokubopha uphawu, umsila weshubhu elithambile uvalwe ngesimo esiyindilinga esiyindilinga ngaphansi kokuqina kobunzima obukhulu obungenzeke ngesenzo somshini. Ngoba lesi simo se-thubhu seaving asisihle futhi sikhulu kuphela, kepha futhi singavimba ngempumelelo ikhilimu ukuvuza nokungcola, ukuqinisekisa ikhwalithi nokuphepha komkhiqizo. Ukuvalwa kwesiyingi se-Semi-Circular kulungele izinhlobo ezahlukahlukene zamashubhu athambile namashubhu epulasitiki we-aluminium, okungahlangabezana nezidingo zokupakisha zemikhiqizo ehlukene. Le ndlela yokuvalwa uphawu iyathandwa kakhulu ngabathengi abaningi.

"I-Punch hole yendiza" emkhakheni wokufaka imishini yokupakisha, ikakhulukazi emishini yokupakisha yeshubhu, imvamisa ibhekisela kubuchwepheshe obukhethekile bokubopha umsila. Lobu buchwepheshe noma imishini isetshenziselwa ukusayina umsila weziqukathi zokupakisha njengamashubhu, bese wakhe umgodi omncane ngesimo sewindi lendiza emsileni, bese unqamula impahla yomsila owedlulele. Ubuchwepheshe be-File Hole Boacaling buchwepheshe busebenzisa ubuchwepheshe bokushisa kwangaphakathi noma ukushisa okuthe xaxa kanye ne-Fusion ephezulu yengcindezi ngaphansi kwengcindezi yezingxenye zemishini ukuze kuqinisekiswe ukuqina kwendawo yokubekwa uphawu kwe-hose. Lobu buchwepheshe buwugcini nje ngokuthuthukisa ukwethenjwa kwenqubo yokuvalwa kwe-tube, kodwa futhi kwenza uphawu luveze ukubukeka okuhle nokuhle. Ishubhu elithambile le-tube amukelwe indiza ye-punch tube ukugcwaliswa kwesisekelo sokugcwalisa isisekelo senziwe ngokwezifiso ngokuya ngezidingo zamakhasimende kanye nosayizi womkhiqizo punch hole, i-mold dissuble kanye nokuhlanza kulula kakhulu

I-Wave tube uphawu njengento eyingqayizivele yokumaketha into ethile, ukwakhiwa kokubekwa uphawu kwe-wavy kwanelisa ilukuluku lemakethe ye-cosmetics emakethe, lo mklamo ungadonsela ukunaka kwabathengi kanye nokwandisa umehluko womkhiqizo. Ukubekwa uphawu kwe-wavy kunesikhalo esibonakalayo, ukubukeka okuhlukahlukene, futhi kulula ukusisebenzisa, ukuqinisekisa ukuguquguquka kwenqubo yokukhiqiza futhi kwalonge ngempumelelo isithombe somkhiqizo. I-Plassist Sealer yenza ukubekwa uphawu kwe-wavy kube yinto ebalulekile yokuklama ukuthuthukisa ukuncintisana kwemakethe.

Isikhathi sePosi: Nov-13-2024