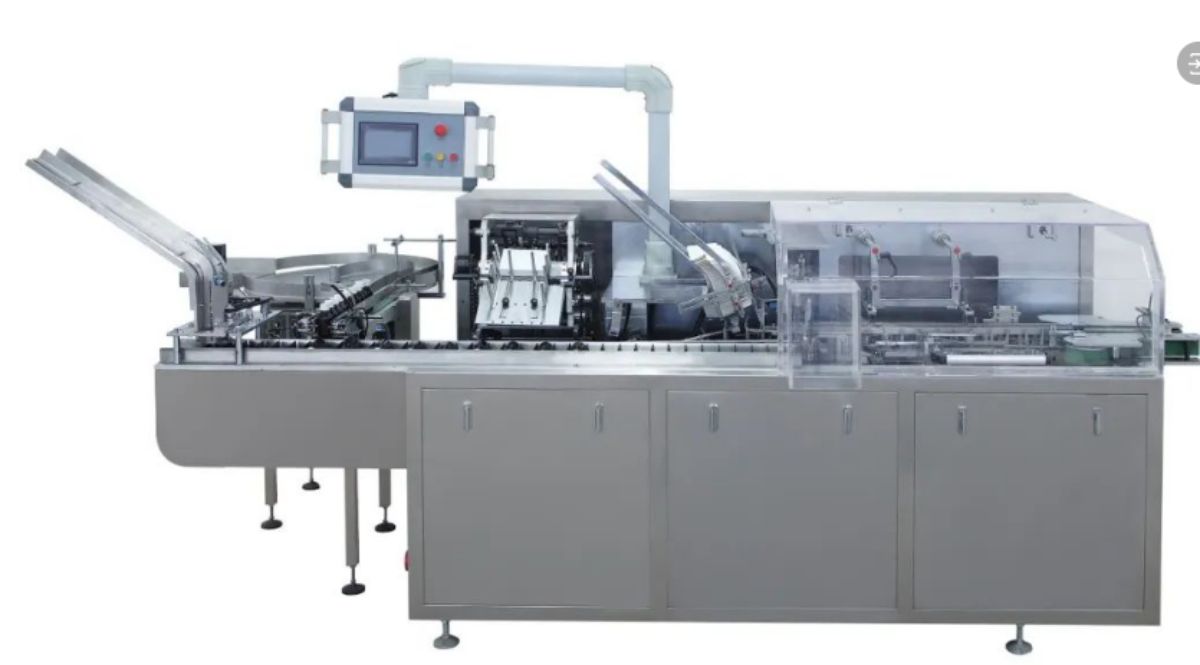

Umatshini wekhathuni wekhathuni yenzelwe ukubonelela ngempumelelo kunye nokuthembeka kumgca wokuvelisa, ngaloo ndlela ugqiba umsebenzi ophezulu. Nangona kunjalo, ukuqinisekisa oku kufezekisiwe kwaye kuqinisekiswe ukusebenza ngokukhuselekileyo, kukho iinkcukacha ezifuna ukuqwalaselwa

1. Cwangcisa iiparamitha ezichanekileyo zeumatshini wekhathuni

Abakhweli boomatshini abahamba ngenqwelomoya kufuneka baqonde iiparamitha eziphambili zomatshini njengesantya, uxinzelelo, isantya sokuhambisa, inani leekomityi nganye, njl njl. Ukuseta ngokuchanekileyo kweeparamitha zomatshini kuya kuqinisekisa ukusebenza.

2. Uqhelene nomatshini womatshini womatshini wekhathuni le-Autoner

Ukuqhelana nesakhiwo kunye neenkqubo zokusebenza komatshini wekhathuni wekhathuni kubalulekile kwaye inyathelo elibalulekileyo ukuthintela ukungasebenzi kakuhle. Ngaphambi kokuba usebenzise umatshini wokudibanisa, kufuneka uqonde ngokupheleleyo indawo, umsebenzi kunye nendima yecandelo ngalinye. Kwangelo xesha, kuya kufuneka ubeke umkhwa olungileyo xa usebenza kuwo onke amacandelo kunye neenxalenye zomatshini wekhathuni ye-coarner ukuqinisekisa ukuba zonke zilungile

3. Phuhlisa amanyathelo okhuseleko kumatshini wokuhamba kwamazinyo

Xa usebenzisa umatshini wokuhlamba izinyo, kufuneka unikele ingqalelo kukhuseleko. Abasebenzi kufuneka basebenze kwindawo evaliweyo yokusebenza kwaye baphuhlise amanyathelo okhuseleko. Ngexesha lokusetyenziswa komatshini wokuhlekisa, umqhubi kufuneka abophe iinwele zakhe, unganxibi amacici, kwaye unganxibanga iimpahla zokuthintela ingozi.

4. Ukubeka iliso kuMatshini wokuSebenza kumatshini wamazinyo

Umatshini wokucoca amazinyo kufuneka ubekwe esweni ngokufanelekileyo ukuze uqiniseke ukuba iyasebenza ngokufanelekileyo. Emva kokuqala umatshini, iziphumo zayo kufuneka zibekwe esweni ngokusondeleyo ukuqinisekisa ukuba zonke iimveliso okanye iinxalenye ziveliswa njengoko bekucwangcisiwe. Ukongeza, abaqhubi kufuneka bahlole rhoqo umatshini womatshini wokucoca amazinyo, kubandakanya nokugcinwa nokuhlaziywa, ukuqinisekisa ukuba umatshini uhlala ekwimeko elungileyo.

5. Qinisekisa ukuba indawo yokusebenza icocekile kumatshini wekhathuni

Ukucoceka kwendalo yokusebenza kubalulekile ekusebenzeni komatshini womatshini wekhathuni. Ngexesha lokusetyenziswa, indawo yokusebenza kufuneka icocwe rhoqo ukuqinisekisa ukuba imeko yemveliso ihleli iphezulu kunye ne-novienic. Oku kubandakanya ukubambelela ngokungqongqo kwisikhokelo sococeko kunye nokucoca rhoqo nokubulawa kwabantu, oomatshini kunye nezixhobo.

I-6. Gcina iziphumo zoMatshini

Imfuneko yokusebenza okuqhelekileyo kweumatshini wekhathunikukulungisa kakuhle kwaye ugcine iziphumo zoomatshini. Abanini zithuthi kufuneka bavule umatshini wekhathuni wekhathuni rhoqo kwaye ujonge ukuba i-oyile inyibilikisa yanele. Ngakumbi kumsebenzi wokulondolozwa rhoqo, kuya kufuneka uphephe ukusebenzisa ilaphu elomileyo ukuze usule amabala e-oyile kumatshini, hleze abe namabala oyi-oyile awonakali.

7. Cwangcisa abasebenzi ngokufanelekileyo

Xa ubaleka umatshini wekhathuni ye-carnerar, kubalulekile ukucwangcisa abasebenzi ngokufanelekileyo ukuqinisekisa ukuba i-manO yakho eyaneleyo yokusebenza. Ukuba kukho ukunqongophala kwabasebenzi, ke imveliso iya kuncipha. Ukugcina abasebenzi ngokuvakalayo sesinye sezitshixo zokuqinisekisa ukusebenza kakuhle komatshini wokutsala.

8. Ngexesha elifutshane, iinkcukacha zokusebenzisa umatshini wokuhamba kwamazinyo kufuneka zithathele ingqalelo iinkalo ezininzi, kubandakanya useto lomatshini, ukubekwa komatshini, amanyathelo okhuseleko, ukucocwa kwemisebenzi, kwaye ezi kufuneka zilandelwe ngokungqongqo. Abanini zithuthi kufuneka bahlale bephaphile kwaye bebeka iliso ngokusondeleyo ukusebenza komatshini wokucoca ukuqinisekisa ukuba isebenza ngokufanelekileyo nangokufanelekileyo. Ukuqwalaselwa kwezi nkcukacha kuya kuqinisekisa ukusebenza ixesha elide lomatshini wokuhlekisa kwaye unike isiseko esomeleleyo kwishishini ukufumana impumelelo ephezulu yemveliso kunye neenzuzo eziphezulu.

Ixesha lasemva kwexesha: Mar-01-2024