Umatshini wokugcwalisa i-tub

Inkcazo emfutshane yomatshini wokugcwalisa kwetyhubhu ephezulu:

I-1. I-serso yombane ye-Tube yeThule yeThundu inokuthi ihlengahlengise isantya ngokukodwa, isantya semveliso somatshini we-tyler filler ingahlengahlengiswa.

2,Isantya esiphezulu seTube sokugcwalisa isantya sokugcwalisa umatshini sikwisantya esiphezulu se-320 se-tube egcwalisa imizuzu nganye.Isiqhelo kwisantya esiphezulu se-Gube esimalunga ne-tyube ngomzuzu

2. Isixhobo se-jog sisebenza ngesantya esisezantsi ukuba sibaleka ngokulula

I-3. Iphaneli ephambili (HMI) ukulungelelanisa zonke iisetingi zenqanaba

I-4. Ipaneli yoMsebenzi ibonisa ubungakanani bemveliso kunye nenqanaba lemveliso lokujonga

I-5. Ngokutsho kweemfuno zabathengi, umatshini we-tube uneeseti ezininzi zefomula yetyhubhu ye-filler ebanjelwe kwi-plc

I-6 .. Iphaneli yokulawula umatshini yokugcwalisa umatshini inokubeka imisebenzi yeparamitha

7.. Umatshini wokugcwalisa ityhubhu ngokuzenzekelayo unepaneli yokusebenza ekhuselweyo ngamanqanaba ama-3 olawulo lwegunya

I-8 .. Umatshini wokugcwalisa isantya esiphezulu se-tube, i-tube yokugcwalisa i-Staight yensimbi ye-Staight ene-APREAL ENGCICHEENCE, inqanaba lokhuseleko lifikelela kwi-IP65 okanye ngaphezulu. I-Cable ye-Cable ye-tyler ye-filler phakathi kweekhabhathi zombane kunye noomatshini basebenzisa iitreyi zentambo ezivaliweyo, iintambo zingena phezulu kumatshini kwinqanaba eliphezulu.

Kwixa elizayo, inkqubo yolawulo ye-tube yesantya esiphezulu ye-tube inokusebenzisa i-NEEMNET ingeniso kwi-MES kwaye iqhagamshele kwinkqubo ye-MES.

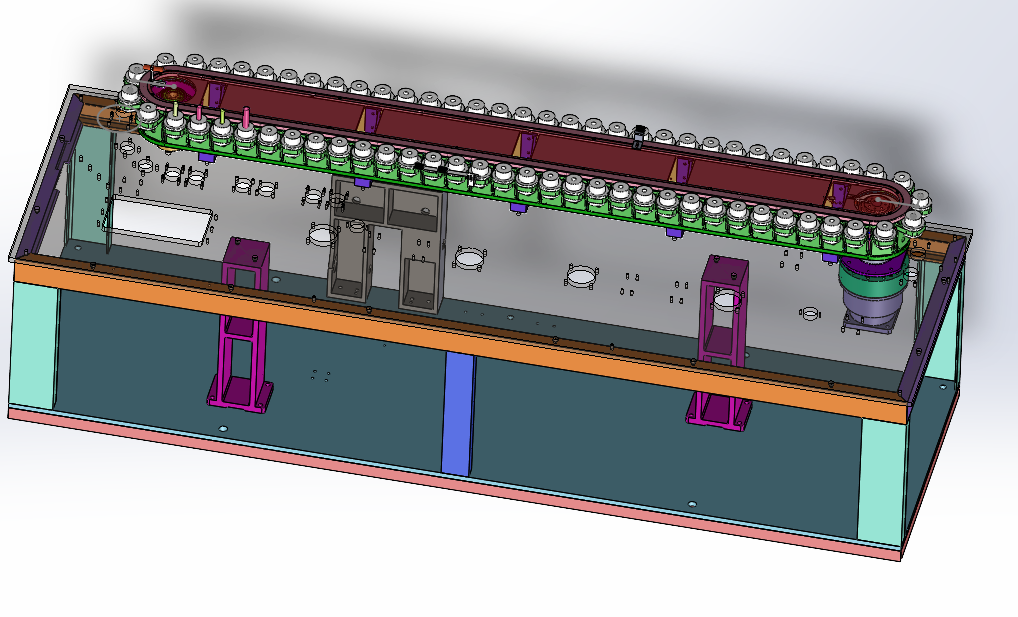

Umatshini wokugcwalisa okuphezulu kwetyhubhu ye-Tube ye-lamote yePlasitiki kunye ne-Aluminium Tube

I-LFC4002 I-TARD SPARING TUBI YOMO sisikhululo sesine esinetiya kunye nokutywina i-tyler filler. Iityhubhu / umzuzu, kunye neyona ndlela iphambili yemveliso yesiqhelo yemveliso ye-tyler i-250-340 tube / umzuzu. Ukugcwalisa ngokuchanekileyo yi- ± 0.5%. Inxalenye ye-Aluminium Tube ityhubhu itywinwe ngokusongela ukutywina, i-Aluminium-Play-Play-Play-Play ityhubhu itywinwe ngumoya oshushu okanye itekhnoloji ephezulu

Isantya esiphezulu se-Tube sokugcwalisa i-tube ye-tube yokugcwalisa i-sub:

Umatshini wokugcwalisa kwetyhubhu ephezulu Ukwamkela isikhokelo se-Alloty Steelis, i-anti-fibiration ye-virder ye-Tube ye-Tebe ye-Tebe ye-Tube ye-Tube yeKhenketho, iseti ye-4kWW ye-4KW ye-4KW ye-4KW ye-4KW ye-4KW ye-CROOR PROOR. Olu matshini wesantya esiphezulu umisela isantya esiphezulu se-tube ephezulu @ 320 I-Tube Gcwalisa ngemizuzu nganye kunye nokuzinza kwi-tube yeplastiki yokutsala kunye nokupakisha

Isantya esiphezulu seTube sokugcwalisa i-tube yekomityi ye-tub idlulisela isixhobo sinemigangatho emithathu ye-whood, esezantsi kunye necala elisecaleni. Iibherithi ezintathu eziqengqelekayo zifakwe kwisihlalo sekhemithi ye-tube, kwaye iibherings eziqengqelekayo zihamba ngendlela ethe tyaba kwaye iqhube iityhubhu. Ukugcwalisa i-chain yomatshini akunakuphatha ixesha elide ukubaleka. Kukwakho nee-rolles ezimbini eziphezulu nezezantsi ze-roller ezikhutshelwe kwi-pins yokujikeleza ubungakanani be-tube yokutshintsha.

Umatshini wokugcwalisa okuphezulu kwi-Tube, i-tub yokuhambisa i-tin hinges kwaye ilungisa izihlalo zetyhubhu (isikhundla esithathu, isikhokelo sentsimbi) omnye komnye ngebhanti le-toced. Ibhanti ye-Toodhed ye-Tube yokugcwalisa i-tube ibaleka ngokungqongqo ngokomlo wokuhambisa ivili levili lokuqhuba. Ikomityi ye-Tube ikhwelwe kwi-Tube nganye yeTub. Umatshini wokugcwalisa uneekomityi zetyhubhu eziyi-116 ze-tebe uqiniseke ukuba i-Tube ephezulu ye-320 i-tube / yekomityi ye-tube / yekomityi ye-tube ye-tube ye-tube ye-tube ye-tym kwaye ihlangabezana neemfuno zeTube kunye neemfuno zoyilo.

I-Tood Seub Sub Gube yokuGqibezela i-Tain Consun inomthwalo ongaphezulu wenziwa yimvelaphi yemvelaphi ye-Synchronous Synchronous efakwe kwivili lokuhambisa, elinobomi benkonzo ende. Ukuba i-tube ye-tube ibambekile, i-clutch ikhutshiwe, i-switchmeity switch igqityiwe, kwaye umatshini uyema ngokukhawuleza nakwisantya esiphezulu sokusebenza

Isantya esiphezulu seTube sokugcwalisa i-Tube

I-1. I-sub yesantya sokugcwalisa umatshini wokugcwalisa umatshini wokugcwalisa umatshini kunye ne-hopper inokucocwa ngokuzenzekelayo sisikhululo se-CIP kwilog evaliweyo ngaxeshanye.

2. Ngaphambi kokuqala i-cip yomatshini wokugcwalisa kwe-Tube ephezulu, i-tube yokugcwalisa i-billy ye-filler ifakwe kwi-dummy ekhethekileyo ye-CIP nge-pube yokutywina kwikomityi ye-CIP dummy ye-CIP Dummy.

I-3. I-CIP yokusebenzela (ebonelelwe ngumthengi) ibonelela iarhente yokucoca kwi-hopper ye-hipper ye-tube yesantya esiphezulu seTube. Ibhola yokutshiza ifakwe kwisilinda, kwaye ibhola yokutshiza iphosa iarhente yokucoca kumphezulu we-cylinder. Inkqubo yokugcwalisa i-typecal tabe yomatshini yenziwa ngokwemigaqo yococeko, kwaye i-CAP yokucoca i-cimp ingafikelela kumatshini wokugcwalisa isantya seTube, imipheliso kunye nezixhobo zenkqubo ye-Tube yeTub. Iindawo ezihambayo zomatshini we-tyler filler onxibelelana nemveliso ngexesha lenkqubo, njengeempuphu ze-piston, ziya kujikeleza ngokufanelekileyo ngexesha lokucoca i-CIP ukuqinisekisa ukuba yonke indawo eshukumayo inokucocwa ngokupheleleyo.

I-4. Umbhobho wokudibanisa wolwelo wokucoca ukubuyela kwinkqubo ye-CIP yomthengi ye-cube yokugcwalisa i-Tube (impompo yokubuya ayifakwanga kumda woNcedo)

I-5. Umatshini wokutywina kwetywina yeplastiki unokuzihlalisa ukucoca kunye nokuchithwa kweentsholongwane ngokweemfuno zabathengi, kwaye konke ukucoca nokubulala intsholongwane kulungiselelwe kwisikhululo se-CIP

I-6. Iiparamitha ze-tube zesantya esiphezulu seTube ezifana ne-parameter ephezulu yesantya. Iqondo lokushisa, uxinzelelo, ireyithi yokuhamba kunye nexesha lomjikelo we-CIP lungasetwa sisikhululo se-CIP ngokweemfuno zabathengi.

I-7. I-Nozzles zokugcwalisa i-typles ye-tube yeplastiki inokuchongwa ngokukhawuleza kwinkqubo yempompo yokucoca ngaphandle kweintanethi.

I-8.CIP traffic ifuna ukuba umatshini wokugcwalisa okuphezulu kwi-tube yi-2T / h okanye ngaphezulu

Umatshini wokugcwalisa okuphezulu kwi-tube yamkela iirobhothi ukondla iityhubhu (iityhubhu ze-15x2 zithathwe kabini imiqolo nganye, i-9-12 / umzuzu):

Ngokwenkqubo yenkqubo yenkqubo, umatshini wokugcwalisa we-tube ephezulu kakhulu unerobhothi esuka kwibhokisi ye-tube emiselweyo, kwaye uzifaka kwikomityi ye-tube, kwaye isebenzisa intsimbi ye-tube, kwaye isebenzisa intsimbi engenasiseko yokuqinisa iminwe. Ingancitshiswa ukuba icoceke kunye nokubulala iintsholongwane okanye i-disticgen nge-hydrogen peroxide xa i-filler ephezulu ime

Umphetho ubona nokuba kukho i-tubeleft yomnwe werobhothi engafakwanga kwikomityi ye-TUBE, kwaye iyenza indlela yokukhupha i-cube ukususa ityhubhu, emva koko iqhubeke ityhubhu.

I-LFC4002 umatshini wokugcwalisa we-Tube weTube unezi zinto zilandelayo:

a. Inkqubo yokuLawula: Umatshini wokugcwalisa kwe-Tube ephezulu Ingxolo ingaphantsi kwe-75 ye-decibels.

b. Indlela yokugcwalisa i-Index: Umatshini wokugcwalisa usebenzisa inkqubo ye-serso njengesandisi sesantya esiphezulu se-rube, siqinisekise ukuba isantya se-tube seplasitiki sigcwalisa isantya esiphezulu se-260PC esizalisa ngemizuzu ephezulu

c. I-CUP COFIAN: Umatshini wokugcwalisa ityhubhu ngokuzenzekelayo yamkela i-New-Indessing Isikhokelo sokugcwalisa isantya, i-Aloty Steeling I-Teel Affic Order Commul Indebeli xa umatshini wesantya esiphezulu esiya kuqhuba

d. Ukwahlulwa kweendawo: Ukugcwaliswa kwetyhubhu yeplasitiki inomsebenzi wokuzicoca ngokwakho, i-robot yomatshini weTub, ityhubhu ye-robo ye-cube, i-servo flap ye-tube ikhutshiwe kunye neemfuno ze-GPE.

e. I-tube ibhokisi yebhokisi ye-tube: Umatshini wokugcwalisa i-tube ngokuzenzekelayo yamkela ukuthuthwa kabini. Ibhokisi ye-tube ithuthwa kwi-ofisi ephezulu, ibekwe kwiqonga elikhohlakeleyo, kwaye ibhokisi engenanto ibuyiselwe kwi-subter engezantsi.

f. Indlela yokulayisha i-Tube: irobhothi okanye umatshini wokulayisha ityhubhu kungena iityhubhu, kwaye unokugcina iityhubhu ezingama-3000 ukuya-4000 ixesha ngalinye.

H. I-servo Benchmark

i. Ukugcwalisa koomatshini bokugcwalisa ityhubhu ngokuzenzekelayo, yamkela i-Doldor-Line Doldo Drive kunye nempompo epheleleyo ye-phumela, engasoze isuswe.

j. I-Aluminium Tube i-cube kunye neflatting: I-Clampleting kunye nendlela yokuThembela yendlela yokutywina yomsila yayiyi-scal yohlobo lwe-scal yohlobo lwe-scal yohlobo, enokucinezela ngokulula ityhubhu. Itshintshelwe kwi-shoriting ethe tyaba kunye nendlela yokubhabha, engenaluthuli kwaye inokuthintela ukuqhuba irhasi.

k. I-Aluminium Tube Tail Twial: Xa itywina umsila we-tube, esonga i-tube, i-shoning yamkela inyathelo lomgca othe tyaba othe tyaba (i-Arc-up yohlobo lwe-ARC) ngaphandle kokutsala ityhubhu phezulu. Oku kulungele kakhulu imisila ye-3.

n. Isixhobo sokukhupha: I-servo ikhupha ityhubhu yendlela ezine kwaye inomsebenzi wokwaliwa.

o. I-Synchrononous idlulisela: Intshukumo ye-servo ye-serso, umnqamlezo owahlukileyo odlulisayo, ungqamaniso olulungileyo.

p. Uxinzelelo I-HOPRER: Unganikezeli ngendlela yokuvula ekhawulezileyo yombhobho wokusasaza ukuze uqhagamshele kwimpompo yokugcwalisa.

Q. I-intanethi ye-intanethi: inokucocwa kwi-intanethi okanye ngaphandle kweintanethi.

Ipharamitha yobugcisa

- I-Tubes Gcwalisa izixhobo eziphambili zeParameter

| No | iparameter | amagqabantshintshi | |

| I-Tube Ingcaciso (MM) | Ububanzi 13 ~ 30, ubude 60 ~ 250 |

| |

| Umbala wamanqaku ombala (mm) | ± 1.0 |

| |

| Ukugcwalisa ubungakanani (ml) | I-1.5 ~ 200 (dibanisa imigaqo-nkqubo ye-5g-50g Imigaqo, imigaqo ethile kunye nesayizi ngokweentlobo kunye netekhnoloji) |

| |

| Ukugcwalisa ukuchaneka (%) | ≤ ± 0.5 |

| |

| Ukutywina imisila | I-sperden-foulling, i-ezintathu-ezintathu, kunye neefolda ezinesarddled ziyafumaneka. |

| |

| Isiphumo semveliso | I-250-300 ityhubhu ngomzuzu |

| |

| Ityhubhu efanelekileyo | I-Alumuminum Pipe Poipe i-Aluminum yeplastiki yombhobho |

| |

| Ukusetyenziswa kwamandla (kW) | ityhubhu ye-filler | 35 |

|

| Irobhothi | 10 |

| |

| Amandla | I-380v 50hz |

| |

| uxinzelelo lomoya | I-0.6MPA |

| |

| Ukusetyenziswa komoya (m3/ h) | 20 ~ 30 |

| |

| Ifomu yokuhambisa i-chain | (Ingeniswe evela kwi-Itali) i-Remonchronous yebhanti (i-serso drive) |

| |

| Indlela yokuhambisa | I-senso epheleleyo ye-senso |

| |

| ubungakanani (mm) | Ubude abangama-3700 ubude be-2000 ubude 2500 |

| |

| Ubunzima be-kg (kg) | 4500 | ||

I-smart zhitong inabayili abaninzi abaziingcali, abanokuyilaUmatshini wokugcwalisa iityhubhuNgokweemfuno zokwenyani zabathengi

Nceda unxibelelane nathi ngoncedo lwasimahla @Wonspp +86I-15800211936

Ukuzalisa kunye nokutywina kwenkqubo yokutywinwa kwenkonzo yezempilo

1. Uhlalutyo lwemfuno: (i-URS) kuqala, umnikezeli weenkonzo zokusebenzela uya kuba nonxibelelwano olunzulu nomthengi ukuze baqonde iimfuno zemveliso yomthengi, iimpawu zemveliso, iimfuno zemveliso kunye nolunye ulwazi oluphambili. Ngohlalutyo lwebango, qinisekisa ukuba umatshini obekwe ngokufihlakeleyo unokuhlangabezana neemfuno zabathengi.

2. Isicwangciso soyilo: Ngokusekwe kwiziphumo zohlalutyo lwemfuno, umboneleli ngeenkonzo zokusebenzela uza kuphuhlisa isicwangciso soyilo esineenkcukacha. Isicwangciso soyilo siza kubandakanya uyilo lomatshini, uyilo lwenkqubo yokulawula, uyilo lwenkqubo, njl.

3. Imveliso eyenziwe ngokwezifiso: Emva kwesicwangciso soyilo siqinisekisiwe ngumthengi, umboneleli-nkonzo weenkonzo zokweziseko uya kuqala umsebenzi wokuvelisa. Baza kusebenzisa izixhobo ezikumgangatho ophezulu kunye namacandelo ngokungqinelana neemfuno zesicwangciso soyilo ukwenza izicelo zokugcwalisa kunye noomatshini bokutywina abahlangabezana neemfuno zabathengi.

I-4. Ukufakelwa kunye nokuhlambumba: Emva kokuba kwenziwe imveliso kugqityiwe, umboneleli-nkonzo weenkonzo zokwenza ngokweziseko uya kuthumela iingcali ezinobuchule kwindawo yofakelo kunye nokuhlanjwa. Ngexesha lofakelo kunye nenkqubo yokuKhulisa, amagcisa aya kuqhuba uhlolo olubanzi kunye novavanyo kumatshini ukuqinisekisa ukuba inokusebenza ngokuqhelekileyo kwaye ihlangane neemfuno zemveliso yomthengi. Nika iinkonzo ezinamafutha kunye ne-SATT

5. Iinkonzo zoqeqesho: Ukuze baqinisekise ukuba abathengi banokusebenzisa ukugcwalisa kunye nomatshini wokutywina, ababoneleli beenkonzo abasebenza ngokuzinzileyo baya kubonelela ngeenkonzo zoqeqesho (njengokugculela kumzi-mveliso). Umxholo woqeqesho ubandakanya iindlela zokusebenza zabasebenzi, iindlela zolondolozo, iindlela zokulungisa ingxaki, njl. Njl.. Ngoqeqesho, abathengi banokufumana ngcono ubuchule bokusebenzisa umatshini kunye nokuphucula ukusebenza ngempumelelo).

I-6. Inkonzo yokuthengisa yasemva kwentengiso: Umboneleli-nkonzo wenkonzo ohlelwe ngokwesiko uya kunika nenkonzo ebanzi yasemva kwentengiso. Ukuba abathengi badibana naziphi na iingxaki okanye bafuna inkxaso yezobuchwephesha ngexesha lokusetyenziswa, banokunxibelelana nomnikezeli wenkonzo obenziwe ngokwezifiso ngalo naliphi na ixesha lokufumana uncedo kunye nenkxaso.

Indlela yokuhambisa: Ngomthwalo kunye nomoya

Ukuhanjiswa kwexesha: Iintsuku ezingama-30 zomsebenzi

I-1.Tube yokugcwalisa umatshini we-1.Tube @ 36PCs / umzuzu:2. Umatshini wokugcwalisa ityhubhu @ 280Cs / umzuzu:I-3. Umatshini wokugcwalisa ityhubhu @ 200Cs / umzuzuI-4.tub yokugcwalisa komatshini @ 180Cs / umzuzu:5. Umatshini wokugcwalisa ityhubhu @ 150cs / umzuzu:I-6. Umatshini wokugcwalisa ityhubhu @ 120cs / umzuzuI-7. Umatshini wokugcwalisa ityhubhu @ 80Cs / umzuzuI-8. Umatshini wokugcwalisa ityhubhu @ 60Cs / umzuzu

Q 1.Yintoni i-tube yakho ye-tube (iplastiki, i-aluminium, ityhubhu ye-abl)

Impendulo, izinto ze-tube ziya kubangela imisila ye-tube yokutywina ye-tube yomatshini we-tyler, sinikezela ngokufudumeza, ukufudumeza kwangaphandle, ukufudumeza, ukufudumeza okuphezulu

I-Q2, ithini ityhubhu yakho kwaye ichanekile

Impendulo: I-Tube yokugcwalisa i-tube yokugcwalisa isikhundla iya kukhokelela kwiSyd System System

I-Q3, ithini into oyilindelekileyo yokukhuphela

Impendulo: Zingaphi iziqwenga ozifunayo ngeyure. Iya kufundisa ukuba zingaphi i-nozzles, sinikezela esinye isibini esinemithathu emithandathu yokuzalisa umthengi wethu kwaye iziphumo zinokufikelela kwi-30 PC / umzuzu

I-Q4, yintoni i-chacumotity yokugcwalisa izinto ezinamandla?

Impendulo: Ukugcwaliswa kokugcwalisa izinto ezinamandla kuya kukhokelela ekukhetheni kwenkqubo yokugcwalisa, sinikezela ngenkqubo yokugcwalisa i-serso, inkqubo ephezulu ye-Pneumatic

I-Q5, lithini iqondo lobushushu lokugcwalisa

Impendulo: Umahluko kubushushu bokugcwalisa uyakufuna umahluko kwi-hopper yezinto eziphathekayo (njenge-hopper, umxube, inkqubo yokulawula ubushushu, i-on cindo uxinzelelo

I-Q6: Ithini imilo yokutywina

Impendulo: Sinikezela ngemo ekhethekileyo yomsila, imilo emi-3D ye-3D yokutywina komsila

I-Q7: Ngaba umatshini ufuna inkqubo ye-CIP

Impendulo: Inkqubo yokucoca i-CIP ikakhulu iquka iitanki, iitanki zamanzi, iitanki zamanzi, iinkqubo zokufudumeza, i-alkali impompo, i-Alkali Acid kunye neenkqubo zoLawulo lweScreen.

Inkqubo ecocekileyo ye-CIP iya kudala utyalomali olongezelelekileyo, oluphambili phantse konke ukutya, isiselo kunye nemixokelelwane yamachiza ye-tyler yethu

Iindidi zemveliso

-

I-imeyile

-

Ifowuni

-

Phezulu

0086 15800211936

0086 15800211936