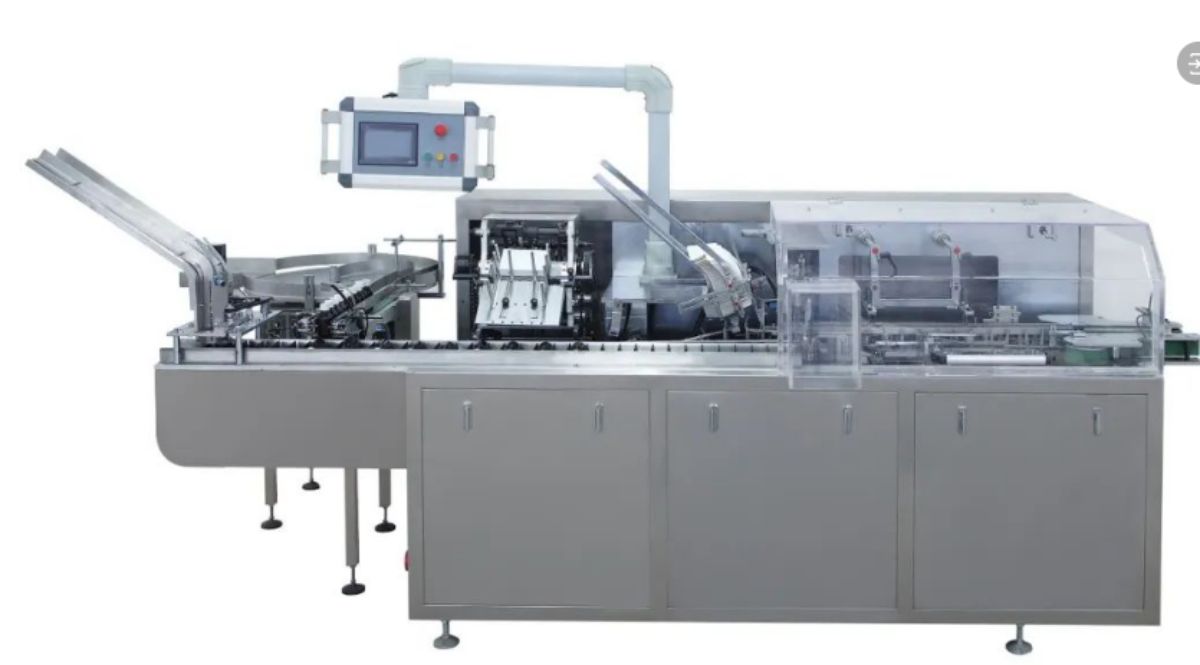

The auto cartoner machine is designed to provide higher efficiency and reliability to the production line, thereby completing more work in a shorter time. However, to ensure this is achieved and ensure safe operation, there are some details that need to be considered

1. Set the correct machine parameters for auto cartoner machine

Auto cartoner machine operators must understand key machine parameters such as speed, pressure, moving speed, number of suction cups, coordinates, etc. Every parameter of the machine must be suitable for the required application. Correct setting of machine parameters will ensure performance.

2. Familiar with the machine structure for auto cartoner machine

Familiarity with the structure and operating procedures of the auto cartoner machine is necessary and an important step to prevent misoperation. Before operating the cartoning machine, you must fully understand the location, function and role of each component. At the same time, you should also establish a good habit when working with all components and parts of the auto cartoner machine to ensure that they are all intact

3. Develop safety measures to Toothpaste Cartoning Machine

When using the Toothpaste Cartoning Machine, you must pay attention to safety. Personnel must operate in a closed operating area and develop corresponding safety measures. During the use of the cartoning machine, the operator should tie his hair back, do not wear earrings, and do not wear loose clothes to avoid danger.

4. Monitor machine operation for Toothpaste Cartoning Machine

Toothpaste Cartoning Machine must be properly monitored to ensure it is operating properly. After starting the machine, its output should be closely monitored to ensure that all products or parts are produced as planned. In addition, operators should regularly check the status of the Toothpaste Cartoning Machine, including inspection maintenance and cleaning, to ensure that the machine remains in good condition.

5. Ensure the working environment is clean for auto cartoner machine

The cleanliness of the working environment is crucial to the operation of the auto cartoner machine. During use, the working environment should be cleaned regularly to ensure that the production environment remains high quality and hygienic. This includes strict adherence to hygiene guidelines and regular cleaning and disinfection of floors, machines and equipment.

6. Maintain machine output

The prerequisite for the normal operation of the auto cartoner machine is to oil it well and maintain the machine's output. Operators should refuel the auto cartoner machine regularly and check whether the lubricating oil is sufficient. Especially in routine maintenance work, you should avoid using a dry cloth to wipe oil stains on the machine, lest the oil stains are not wiped off and instead breed moisture.

7. Arrange personnel reasonably

When running the auto cartoner machine, it is necessary to arrange staff appropriately to ensure sufficient manpower for operation. If there is a shortage of personnel, then productivity will decrease. Maintaining reasonable staffing is one of the keys to ensuring the efficient operation of the cartoning machine.

8. In short, the details of using Toothpaste Cartoning Machine need to consider many aspects, including machine settings, machine structure, safety measures, machine operation monitoring, working environment cleaning, machine output and staffing, etc., and these must be strictly followed and mastered. Operators must remain vigilant and closely monitor the operation of the cartoning machine to ensure it operates properly and efficiently. The consideration of these details will ensure the long-term stable operation of the cartoning machine and provide a solid foundation for the enterprise to obtain higher production efficiency and higher profits.

Post time: Mar-01-2024