Two filling nozzle tube filler for ointment packing 180tubes/minutes

LFC180 High Speed Tube Filling Machine, independently developed, designed and manufactured four filling station full servo rotary tube filling machine new filling machine, this model is stainless steel fully enclosed, suitable for various specifications of sterile or non-sterile aluminum tube and plastic tubes filler design speed 250tube/minutes, the actual maximum normal production speed is 150-200 tubes/minute. Accurate filling is ≤±0.5-1%. The aluminum tube seal sealing method is folding sealing technology, plastic tubes and aluminum-plastic composite tubes are high-frequency heating or internal heating sealing technology.

The factors affecting the high speed of Ointment Tube Filler mainly include the main transmission mechanism, indexing positioning mechanism, tube cup conveyor chain mechanism, lower tube mechanism, alignment positioning mechanism, filling mechanism, sealing mechanism, tube discharge and kicking mechanism and electrical control system.

Machine feature

No Tube No Filling arrangement.

· SS304 airlined pre-finished body.· Single motor synchronizes platform turret.

· Adjustable height with Screw Up down plate movement

· Adjustable Sealing pressure. Low noise level, low power consumptions.

· SS cladding or hard chrome plating of all exposed parts to ensure long life and resistance against corrosion.

· Synchronized A/C drives to synchronize, No Air machine will stop automatically

· Safety Door of Acrylic PLC HMI- Operated machine

· Autoloader Start Stop Set BY HMI Touch Screen In-Built Tube Counter in HMI

· Positive shut off System for drip-less filling

· Hopper Level Sensor Preset tube sealing settings

control with plc -based automatic tube filling dosing

Automatic Tube loading and Discharge device No Tube No Fill function for safety design

Sealing mothed inner hot Air Sealing (set up to 600 Celsius) sick or banner for automatic Tube Orientation

Double Filling Nozzles with air self-blow for the tube cleaning process

Quickly change tube product size tube, easy cleaning

plastic tube filling and sealing machine adopted high-quality SS316 Stainless Steel for Contact Parts

Automatic Cassette Tube Feeding and inclined hanging tube box for option

Bottom-up Filling with drip-proof filling nozzles (high-quality ss 316)

PRODUCT DETAIL

| Model no | LFC180 |

| Tube material | Plastic , aluminum tubes .composite ABL laminate tubes |

| viscous products | Viscosity less than 120000cpcream gel ointment toothpaste paste food sauce and pharmaceutical, daily chemical, fine chemical |

| Tube holder no | 72 |

| Tube dia(mm) | φ13-φ50 |

| Tube height (mm) | 50-220 adjustable |

| Filling capacity(mm) | 5-250ml adjustable |

| Filling volume | A:6-60ml, B:10-120ml, C:25-250ml, D:50-500ml (Customer made available) |

| Filling accuracy | ≤±1% |

| tubes per minute | 150—180 tubes per minute |

| Hopper Volume: | 80 litre |

| Air pressure requirements | 0.55-0.65Mpa 20m3/min |

| motor power | 5Kw(380V/240V 50-60Hz) |

| heating power | 13Kw |

| size(LXWXH )mm | 3200×1500×1980 |

| Net weight (kg) | 4200 |

Main configuration

| Infrastructure | LFC180A | LFC180AB | ||

| Host area | 15m2 | 20 m2 | ||

| Working area | 20㎡ | 25㎡ | ||

| Chiller area | 1㎡ | |||

| Size(L×W×H) | 4350×1300×2200mm | |||

| Net weight | 2500Kg | |||

| Machine box | ||||

| Machine box material | High-quality SS 304 | |||

| Protective device opening method | Door handle | |||

| Protective device material | Plexiglass | |||

| Lower frame | High-quality SS304 | |||

| Box shape | Square | |||

| n Host, power requirements, etc. | ||||

| Power Supply | 50Hz/380V 3Phase+ground line | |||

| Host | 6.0KW | |||

| tube filler capacity tubes per minute | ||||

| Capacity | 80-150 tubes per minute | 200-260tubes per minute | ||

| filling volume | plastic tube 5-250 gram aluminum tubes 3--250 gram | |||

| Tubes length | plastic aluminum tube 50-210mm | |||

| Tubes diameter | plastic aluminum tube diameter size12-50mm | |||

| Electrical control | ||||

| Control method | PLC+Touch Screen(control with plc based) | |||

| PLC | Siemens | |||

| Frequency Converter | Siemens | |||

| Touch screen | Siemens | |||

| Coder | OMRON | |||

| Color code sensor | BANNA | |||

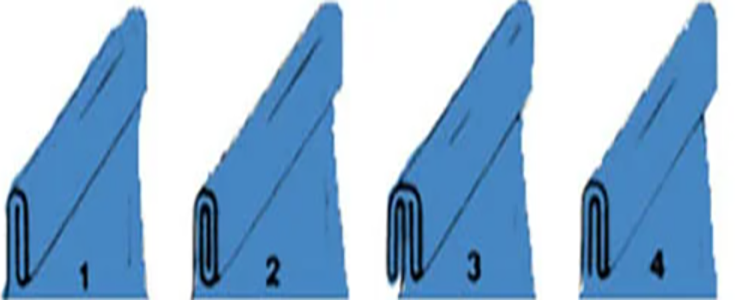

Tube Tail Trimming Shape

For plastic tube Tail Trimming Shape

For aluminum tubes Tail Trimming Shape

Why choice us

1. Committed to becoming the leader of high speed Ointment tube filling machine. Through continuous research ,development & innovation, machine integrates the most advanced tube filling automation technology and precise control system to ensure that each filling can achieve high accuracy and consistency

2. Knowing the importance of hygiene and safety to Ointmen production, the high speed ointment tube filling machine uses high-grade stainless steel materials and is equipped with advanced self-cleaning and disinfection systems to ensure the aseptic operation of the ointment throughout the process, providing consumers with safe and reliable products

3.The flexible modular design makes the high speed machine and filler easy to maintain, reducing downtime and maintenance costs, helping clients to easily cope with changes in market demand

4.With a professional Ointment Tube Filler service team, we will provide full support from filler pre-sales consultation to after-sales service.

Smart zhitong has many professional designers, who can design Tubes Filling Machine according to the actual needs of customers

Please contact us for free help @whatspp +8615800211936

Products categories

-

E-mail

-

Phone

-

Top

0086 15800211936

0086 15800211936