Tubes Filling Machine for plastic laminate and aluminum tube(up to 320 ppm)

Brief Description of High Speed Tube Filling Machine:

1. The electrical servo of High Speed Tube Filling Machine can adjust the speed individually, the production speed of the tube filler machine can be adjusted.

2,High Speed Tube Filling Machine design speed is at high speed 320 tube filling per minutes.and the normally high speed is about 280 tube filling per minute

2. The jog device operates at low speed for easier running

3. Main panel (HMI)to adjust all production processing diameter settings

4. The operation panel displays production quantity and production line status for monitoring

5. According to customer needs, tube machine has multiple sets of formulas for tube of filler storaged in PLC

6.. The High Speed Tube Filling Machine control panel can set parameter functions

7.. The automatic tube filling machine has an operation panel protected by 3 different operation levels for authority management

8.. High Speed Tube Filling Machine adopted Stainless steel independent electrical cabinet with air conditioning, protection level reaches IP65 or above. The cable trays of tube filler between electrical cabinets and machines use closed cable trays, cables enter from the top of the machine at a high level.

In the future, the control system of High Speed Tube Filling Machine can use Siemens profitnet to transfer data to MES and connect with the MES system.

High Speed Tube Filling Machine for plastic laminate and aluminum tube

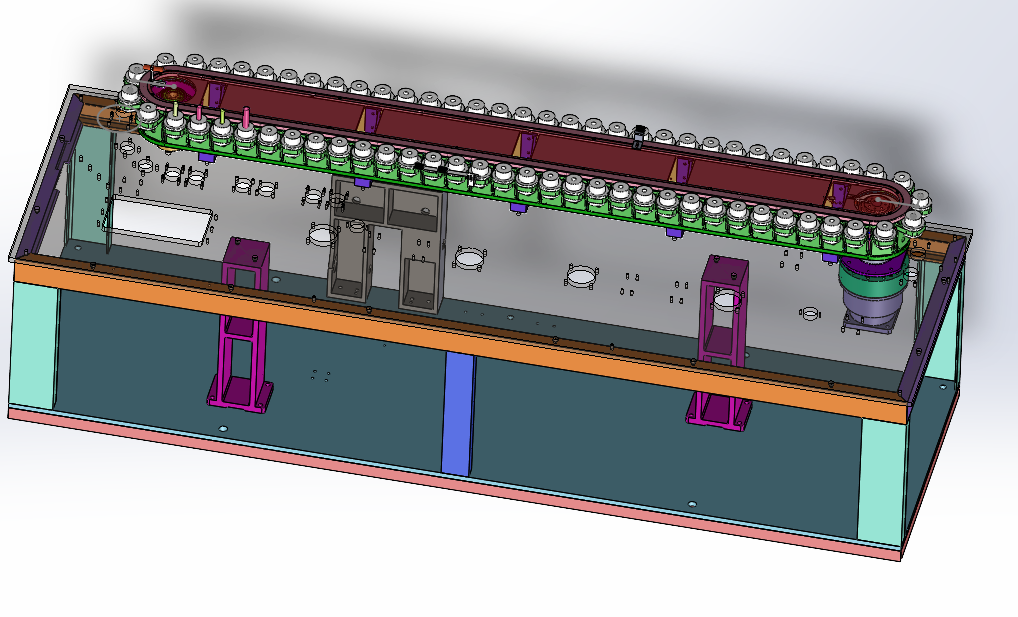

LFC4002 High Speed Tube Filling Machine is a four-station filling and sealing tube filler .employed full-servo plastic tube sealing machine independently developed, designed and manufactured by our company designed speed is about 320 tube filling per minute ,high speed tube filler is suitable for filling various specifications of sterile or non-sterile environment wildely used for aluminum-plastic composite tubes, plastic tubes and aluminum tubes filling process , The design speed is 320 tubes/minute, and the actual maximum normal production speed of tube of filler is 250-340 tubes/minute. filling accuracy is ≤±0.5%. The aluminum tube mechanical part is sealed by folding sealing, aluminum-plastic composite tube is sealed by hot air or high frequency heating technology

High Speed Tube Filling Machine Main transmission mechanism:

High Speed Tube Filling Machine adopts an alloy steel integral guide rail, an anti-vibration three-bearing tube cup holder locking mechanism, a set of 4kW servo intermittently driven tube cup conveyor chain mechanism. this high speed machine determines the maximum high speed @320 tube filling per minutes and stability for plastic tube filling and sealing packing

High Speed Tube Filling Machine tube cup chain conveying device consists of three grooved upper, lower and side alloy steel guide rails. Three rolling bearings are installed on the tube cup seat, and the rolling bearings move directionally in the grooves and drive the tubes . Filling Machine chain has no wear for long time running . There are also two upper and lower needle roller bearings mounted on pins for rotation for the tube size changing.

High Speed Tube Filling Machine ,the tube conveyor chain hinges and fixes the tube seats (three-bearing positioning, steel guide rail) to each other through a toothed conveyor belt. The toothed conveyor belt of tube filling machine runs strictly according to the transmission trajectory of the driving wheel. tube cup is mounted on each tube seat ring. filling machine has 116 tube cups make sure machine can run high speed 320 tube /minutes tube cup is made of high light POM material and meets tube specifications and design requirements.

High Speed Tube Filling Machine conveyor chain has overload protection is performed by an origin return precision synchronous torque limiter installed on the transmission wheel, which has a long service life. If the tube chain is stuck, the clutch is disconnected, the proximity switch is triggered, and the machine stops immediately even in the high speed running status

High Speed Tube Filling Machine eOnline cleaning process

1. High Speed Tube Filling Machine filling system and hopper can be automatically cleaned by the CIP station in a closed loop at the same time.

2. Before starting CIP for high Speed Tube Filling Machine, tube filler's filling nozzle is installed with a specific CIP dummy , cleaning liquid will be discharged from plastic tube sealing machine through the pipeline connected to the CIP dummy cup.

3. CIP workstation (provided by the customer) provides cleaning agent to the entrance of the hopper of from High Speed Tube Filling Machine . A spray ball is installed in the cylinder, and the spray ball sprays the cleaning agent on the inner surface of the cylinder. The plastic tube sealing machine filling system is designed according to hygienic principles, and the CIP cleaning fluid can reach all surfaces of high Speed Tube Filling Machine , pipes and instruments that come into contact with the product during plastic tube sealing machine process. Moving parts of tube filler machine that come into contact with the product during the production process, such as piston pumps, agitators, etc., will also rotate accordingly during CIP cleaning to ensure that all surfaces of the moving parts can be fully cleaned.

4. The connecting pipe for the cleaning fluid to return to the customer's CIP system of High Speed Tube Filling Machine (the return pump is not included in the scope of supply)

5. Plastic tube sealing machine can settup cleaning and disinfection cycles according to customer needs, and all cleaning and disinfection are configured in the CIP station

6. Parameters of high Speed Tube Filling Machine such as high speed parameter. temperature, pressure, flow rate and time of the CIP cycle can be set by the CIP station according to customer requirements.

7. The filling nozzles of the Plastic tube Filling Machine can also be quickly detached from the pump system for offline cleaning.

8.CIP traffic requires for High Speed Tube Filling Machine is 2T/H or above

High Speed Tube Filling Machine adopting robots to feed tubes (15x2 tubes taken in double rows each time, 9-12 times/minute):

According to the programmed program, high speed tube filling machine has robot takes out two rows of tubes from the fixed tube box each time, transfers them to the top of the tube cup,and then inserts them vertically into the tube cup for high speed purpose , The robot has a tube support method, and uses stainless steel to tighten the fingers. can be disassembled for cleaning and disinfection or disinfected with hydrogen peroxide spray when high speed tube filler stopped

The grating detects whether there is a tubeleft in the robot's finger that has not been inserted into the tube cup, and activates the extubation mechanism to remove the tube from the finger, and then proceeds to take the tube.

LFC4002 High Speed Tube Filling Machine has the following advantages:

a. Control system: High Speed Tube Filling Machine adopts Siemens touch screen and Japanese Keyence motion controller, fully servo bus driven; the noise is less than 75 decibels.

b. Indexing mechanism: filling machine uses a servo system as the indexer for machine high speed run @320 tube per minutes purpose ,develops differential software to increase the dynamic to static ratio, lengthen the static time of filling and sealing, ensure that the stable speed of the Plastic Tube Filling Machine is above high speed 260pcs tube filling per minutes

c. Cup chain guide rail: The automatic tube filling machine adopts four-station operation with four filling nozzles for high speed filling purpose, alloy steel integral guide rail, anti-vibration three-bearing tube cup holder locking mechanism when machine is at high speed running

d. Separation of areas: plastic tube filling and sealing machine has tube self-cleaning function , robot machine tube loading, servo flap tube loading, automatic tube unloading, filling and sealing, servo tube discharging and other areas are separated according to GMP requirements.

e. tube box positioning: automatic tube filling machine adopts double-layer transportation. The tube box is transported on the upper layer, positioned on the inclined platform, and the empty box is returned on the lower layer.

f. Tube loading method: Robot or tube loading machine enters tubes, and can store 3000-4000 tubes each time.

h. Servo benchmarking: sick color mark capture signal, large torque servo rotation positioning, high speed and stability.

i. Servo filling: automatic tube filling machine adopts full-line servo drive and full ceramic pump filling, which will never wear out.

j. Aluminum tube clamping and flattening: clamping and flattening mechanism of the tail sealing device was originally a scissor-type clamping flattening, which can easily press air into the tube. changed to a horizontal clamping and flattening mechanism, which is dust-free and avoids driving gas into the tube.

k. Aluminum tube tail sealing: When sealing the tube tail, the folding and clamping adopts bearing-guided horizontal linear movement (originally an arc pick-up type) movement without pulling the tube upwards. This is especially suitable for three-fold tails.

n. Discharging device: The servo ejects the four-way tube and has a rejection function.

o. Synchronous conveying: servo intermittent movement, separate trough conveying, good synchronization.

p. Pressure hopper: adopts the quick-opening mode of the distribution pipe to connect to the filling pump.

q. Online CIP: It can be cleaned online or offline.

Technical parameter

- Tubes Filling Machine Main equipment technical parameters

|

No |

parameter |

remarks |

|

| Tube specification(mm) | Diameter 13~30, length 60~250 |

|

|

| Color mark positioning(mm) | ±1.0 |

|

|

| Filling capacity(ml) | 1.5~200(Meet 5g-50g specifications, specific specifications and sizes according to variety and technology) |

|

|

| Filling accuracy(%) | ≤±0.5 |

|

|

| Sealing tails | Two-fold, three-fold, and saddle-shaped folds are available. |

|

|

| Output capacity | 250-300 tube per minute |

|

|

| Suitable tube | Aluminum pipe Plastic pipe Aluminum plastic pipe |

|

|

| Power consumption(kW) | tube of filler | 35 |

|

| Robot | 10 |

|

|

| Power | 380V 50Hz |

|

|

| air pressure | 0.6MPa |

|

|

| Air consumption(m3/h) | 20~30 |

|

|

| Transmission chain form | (Imported from Italy) Rebar synchronous belt type (servo drive) |

|

|

| transmission mechanism | Full servo drive |

|

|

| size(mm) | Length 3700 Width 2000 Height 2500 |

|

|

| Total weight(kg) | 4500 | ||

Smart zhitong has many professional designers, who can design Tubes Filling Machine according to the actual needs of customers

Please contact us for free help @whatspp +8615800211936

Filling and sealing machine customization service process

1. Demand analysis: (URS) First, the customization service provider will have in-depth communication with the customer to understand the customer’s production needs, product characteristics, output requirements and other key information. Through demand analysis, ensure that the customized machine can meet the actual needs of customers.

2. Design plan: Based on the results of the demand analysis, the customization service provider will develop a detailed design plan. The design plan will include the structural design of the machine, control system design, process flow design, etc.

3. Customized production: After the design plan is confirmed by the customer, the customization service provider will start production work. They will use high-quality raw materials and parts in accordance with the requirements of the design plan to manufacture filling and sealing machines that meet customer needs.

4. Installation and debugging: After production is completed, the customization service provider will send professional technicians to the customer’s site for installation and debugging. During the installation and commissioning process, technicians will conduct comprehensive inspections and tests on the machine to ensure that it can operate normally and meet the customer’s production needs. Provide FAT and SAT services

5. Training services: In order to ensure that customers can use the filling and sealing machine proficiently, our customized service providers will also provide training services (such as debugging in the factory). The training content includes machine operation methods, maintenance methods, troubleshooting methods, etc. . Through training, customers can better master the skills of using the machine and improve production efficiency).

6. After-sales service: Our customized service provider will also provide comprehensive after-sales service. If customers encounter any problems or need technical support during use, they can contact the customized service provider at any time to obtain timely help and support.

Shipping method: by cargo and air

Delivery time: 30 working days

1.Tube Filling Machine @360pcs/minute: 2. Tube Filling Machine @280cs/minute: 3. Tube Filling Machine @200cs/minute 4.Tube Filling Machine @180cs/minute: 5. Tube Filling Machine @150cs/minute: 6. Tube Filling Machine @120cs/minute 7. Tube Filling Machine @80cs/minute 8. Tube Filling Machine @60cs/minute

Q 1.What is your tube material (plastic, Aluminum, Composite tube. Abl tube)

Answer, tube material will cause sealing tube tails method of tube filler machine, we offer internal heating, external heating, high frequency, ultrasonic heating and tail sealing methods

Q2,what is your tube fill capacity and accuracy

Answer: tube filling capacity requirement will lead machine dosing system configuration

Q3,what is your expectation output capacity

Answer : how many pieces do you want per hour. It will leading how many filling nozzles , we offer one two three four six filling nozzles for our customer and the output can reach 360 pcs/minute

Q4,what is the filling material dynamic viscosity?

Answer: the filling material dynamic viscosity will result the filling system selection , we offer such as filling servo system, high pneumatic dosing system

Q5, what is the filling temperature

Answer :difference filling temperature will need difference material hopper (such as jacket hopper , mixer , temperature control system ,position air pressure and so on)

Q6: what is the sealing tails shape

Answer : we offer special tail shape, 3D common shapes for tail sealing

Q7: does the machine need CIP clean system

Answer: The CIP cleaning system mainly consists of acid tanks, alkali tanks, water tanks, concentrated acid and alkali tanks, heating systems, diaphragm pumps, high and low liquid levels, online acid and alkali concentration detectors and PLC touch screen control systems.

Cip clean system will create extra investment , main apply in almost all food, beverage and pharmaceutical factories for our tube filler

Products categories

-

E-mail

-

Phone

-

Top

0086 15800211936

0086 15800211936