Astaamaha

(1) astaamaha ugu waaweyn eeMashiinka isku-darka ilkaha ee ilkaha

Mashiinka midabka cadayga ee midabka ee lagu saleeyay iyada oo lagu saleynayo buuxinta otomatiga ah iyo mashiinka shaabadaysan, muuqaal qurux badan, xawaare sare, oo ah xawaare sare, iyo xasillooni sare oo ah nidaamka ogaanshaha iyo ogaanshaha. Faa'iidooyinka, waxay soo saari kartaa labada midab ama laba-midab laba-midab, iyo sidoo kale daawada cadayga ee caadiga ah. Markaad soosaarto daawada cadayga midabka, saamiga koollada midabka leh ee dharkaaga ugu weyn lagu hagaajin karo si aan kala sooc lahayn oo ah nooc gaar ah, iyo hagaajinta ayaa ku habboon iyo dhaqso. Xirmooyinka midabka ee sheygu waa mid deggan oo qurux badan.

2. Guudmar guud ee tikniyoolajiyadda cadayga

(1) tikniyoolajiyadda midabka badan leh

1. Mabda'a aasaasiga ah ee buuxinta midabka badan

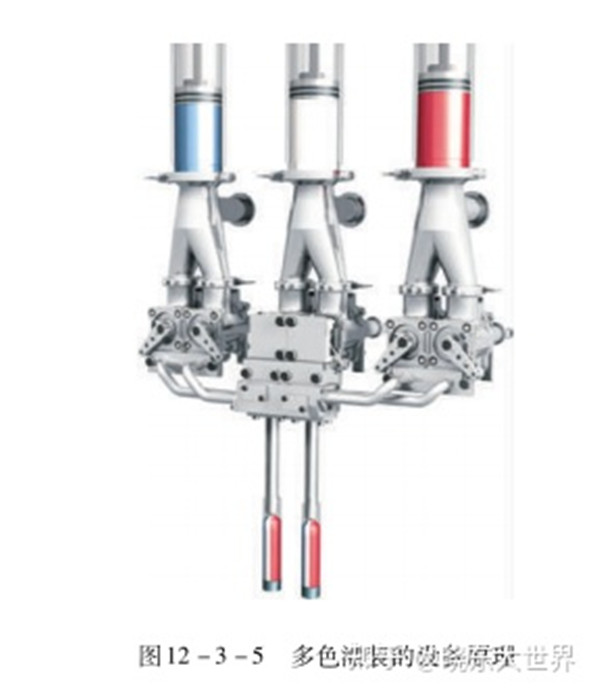

Waxaa lagu xaqiijiyey qalab ka buuxiya khaaska ah ee cadayga cadayga midabka (Sawir 12-3-5). Farqiga u dhexeeya qalabkan buuxinta iyo qalabka buuxinta caadiga ah ayaa ah in ay jiraan wax ka badan laba bogsasho oo buuxinaya, iyadoo kuxiran tirada baararka midabada leh ee midabada kala duwan.

Mabda'a qalabka ee midabka midabka badan

Hal baaldi oo buuxinta waxaa ka buuxa koollada ugu weyn, kan kalena waxaa ka buuxsamay koollada qeybta qarka midabka. Madaxa buuxinta qalabka noocan ah sidoo kale waa mid gaar ah. Waxay u qaybsan tahay unugyo badan. Markaad buuxinayso, daaqado kala duwan ayaa gala qaybo kala duwan oo ah madaxa buuxinta samaynta si isku mid ah, ka dibna ku shub tuubada caadiga ah ee ka kooban. Xirmooyinka midabka ayaa lagu sameeyay tuubada isku-darka ah.

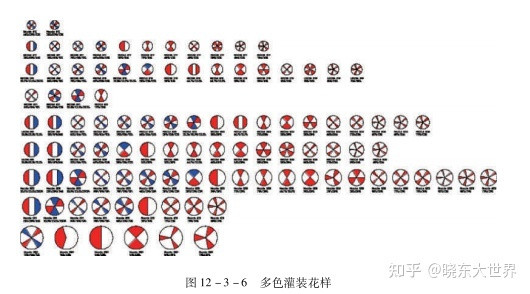

Furaha horumarinta koritaanka cadayga midabka cadayga ee midabka cadayga ayaa ku jira xulashada midabka midabka. Feejiga ugu weyn iyo qaybta qarka midabka waa in la isku dubbaridaa midba midka kale ee naqshada qaaciddada. Hawlaha kaladuwan ayaa la siin karaa koollada qayb kasta oo ka mid ah daaqa cadayga midabka, si loo gaaro midnimada suuxdinta suuxinta iyo waxqabadka, iyo kor u qaadista soo jiidashada sheyga.

Wixii soo saarka baaxadda leh ee cadayga cadayga ee midabka cadayga leh, qalabka ku habboon buuxinta waa in loo xushaa iyadoo loo eegayo shuruudaha dhabta ah ee wax soo saarka. Inta lagu gudajiro hawsha buuxinta, cadaadiska haanta kasta, xamuulka tuubada tuubada, iyo isku xirka bambooyin badan oo buuxinta ayaa si weyn saameyn ugu yeelan doonta saameynta guud ee midabka midabka badan. Teknolojiyad aad u fiican ayaa ah isticmaalka aaladda isku-darka cadaadiska ah (ku dhegan dhululubo kasta), tuubada tuubada sare ee spoto gawaarida iyo buuxinta bamka wadista si sax ah loo hagaajin karo nidaamka kontoroolka dhexe.

2. Noocyada caadiga ah ee midabka midabka badan

Buuxinta Multitror Waa tan ugu badan ee loo adeegsado ee warshadaha cadayga ee ilkaha, iyo daawada ilkaha oo badan oo wax soo saar ah ay isticmaalaan buuxinta midabka badan saddex midab

Smart Zhitong waxay leedahay sanado badan oo waayo-aragnimo badan ka ah horumarka, naqshadeeya mashiinka wax soo saarka dawada sidaQalabka wax soo saarka ilkaha

Haddii aad wax walaac ah qabtid fadlan la xiriir

Waqtiga Post: Noven-08-2022