Tubes faʻatumu masini mo palasitika laminate ma o le alumini o le tube (luga i le 320 ppm)

Faʻamatalaga puʻupuʻu o le maualuga saoasaoa tibe faʻatumu masini:

1. O le eletise eletise o le maualuga o le saoasaoa o le saoasaoa e mafai ona fetuunai le saoasaoa taʻitasi, o le gaosiga saoasaoa o le pu o le pu o le pub

2,O le saoasaoa saoasaoa o le saoasaoa o le saoasaoa o le saoasaoa o le saoasaoa o le saoasaoa o le 320 tube tumu i minute sili atu o le saoasaoa maualuga

2. O le Hog masini e faʻagaioia i le maualalo televave mo faigofie ona tafe

3. Vaega autu (HMI) e fetuunai uma gaosi gaosi

4. O le faʻagaioiga o loʻo faʻaalia ai le gaosiga o le aofaʻi ma le gaosiga laina tulaga mo le mataituina

5. E tusa ai ma tagata faʻatau manaoga, o le masini masini e tele seti o faʻasologa mo le tube o le untlen o loʻo puʻeina i pluc

6. O le maualuga saoasaoa tibe faʻatumu masini pulea e mafai ona seti tapulaʻa

7. o le otometi tibe faʻatumu le masini e iai le vaega o le taotoga e puipuia e 3 eseese faʻagaioiga o le pule mo pulega pulega

8. .. O le maualuga o le sipau faʻatumu le masini e faʻaaogaina ai le tutoʻatasi uamea tufuga tutoʻatasi fale eletise eletise ma le ea, puipuiga tulaga i le ea. O le Cable fata o le pube e faʻapipiʻi i le va o le eletise eletise ma masini faʻaaoga tapunia tapuni cable daley, uaea e ulufale mai le pito i luga o le masini i le maualuga o le tulaga.

I le lumanaʻi, o le faʻatonutonuga o le saoasaoa o le saoasaoa o le saoasaoa o le faʻatumuina o masini e mafai ona faʻaaoga le masini SIEMENTS.

High Speed Coabe tumu masini mo palasitika laminate ma almininum tube

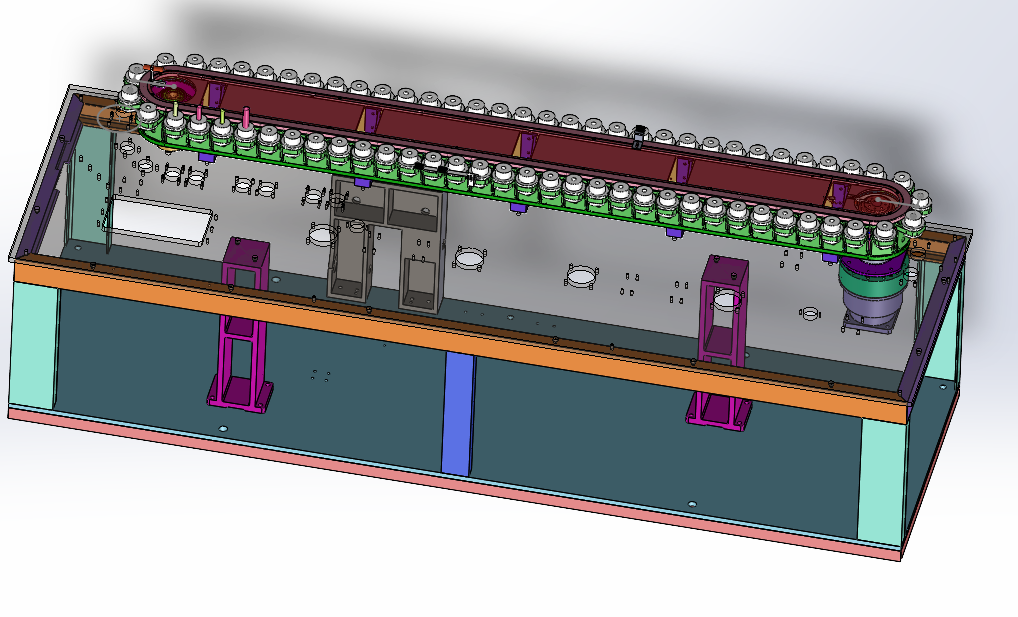

Lfc4002 maualuga saoasaoa tibe tumu masini O le fa-lea-nofoaga faʻatumu ma faʻamaufaʻailoga o le pube pupuga. Lei o le sili-consic tipling stare o le preping, o le sipuni tele o le 320 tubes / minute, ma o le mea moni sili ona masani masani masani gaosiga o le utu o le unit o le 250-340 tubes / minute. Faʻatumu le faʻamaoni o le ≤ ± 0.5%. O le almininum tibe masini o loʻo faʻamaufaʻailogaina i le faʻapipiʻiina o le faʻapipiʻiina o le faʻamaufaʻailoga, o le palasitika-palasitika tuufaatasia o le paipa vevela poʻo le maualuga masani

High Speed Coabe Faʻatumuina le masini autu o loʻo lafoina masini:

Maualuga saoasaoa tibe tumu masini vaetamaina o se faʻailoga uʻamea faʻailoga faʻatonutonuina o le nofoaafi, o le anti-vibrasion tolu-faʻapipiʻi paipa ipu ucer skings coupontis cupyor O lenei maualuga saoasaoa masini e fuafua ai le maualuga maualuga saoasaoa @ 320 tube tumu i minute ma le mautu mo palasitika liu

O le saoasaoa o le sipi sili ona faʻatumuina masini o le suauʻu o le cube chean chean o loʻo aofia ai le mea e aofia ai i le tolu groud i luga, lalo ma le itu o le uʻamea pulupulu. E tolu ni mea e faʻapipiʻi i luga o le nofoa o le paʻu i luga o le nofoa o le paʻu, ma o le au fanafana e agai atu i totonu o fale ma ave le umu. O le faʻatumuina o masini e leai se ofu o le taimi mo le taimi umi e tamoe ai. E i ai foʻi ma le lua pito i luga ma lalo o le Scorle Barller Beat o loʻo faʻaulu mai i luga o pine mo le fesuiaʻiga o le pati o suiga.

O le maualuga o le sipi sili ona faʻatumuina masini, o le faagasolo o tagata vaʻalele o loʻo nofo ai ma faʻasaʻoina le suauʻu nofoa (tolu-o loʻo iai le tasi i le isi e ala i le isi e ala i le isi e ala i le isi e ala i le isi. O le Menthed Confivey Bealt of Tabe Encopting masini e tamoe malosi e tusa ai ma le lafoina o le auala o le taavale uili. O le ipu o loʻo tuʻuina atu i luga o le taʻele o le utupoto taʻitasi. Faʻatumu masini e 116 Tane ipu ia mautinoa e mafai ona tamoʻe ai le siʻusiʻu o le tele o le saoasaoa o le tele o le tele o le tele o le saoasaoa 320 o le ipu moli lanu ma faʻafefe.

O le saoasaoa o le sipai maualuga o le faʻaaogaina o le conveyor chain e faia le puipuiga o le toe faʻafoʻiina e se amataga o le cyncronous cyqueser preved Afai o le paipa filifili e pipii, o le piula ua vavaeeseina, o le auala latalata, ma ua amata ona taumafai le masini i le saoasaoa tele

High Speed Tabe Faatumuina masini Eleeline Faamamaina

1. O le maualuga saoasaoa tibe faʻatumu masini faʻatumu masini ma hopper mafai ona faʻamamaina e le cip nofoaga i le taimi tutusa.

2. A o le i amataina CIP Mo le saoasaoa o le saoasaoa o le saoasaoa o masini, o le o loʻo faʻapipiʻiina ai le uni o le paʻu ma le pipi o le pipi.

3. Cip falefaigaluega (saunia e le tagata faʻatau) maua ai le faʻauiga o le faʻaaogaina o le hopper o le sipai sili. O le spray polo ua faʻapipiʻiina i totonu o le kalone, ma o le spray polo e sprays o le faʻamamaina o le faʻauiga i totonu o le ogaumu. O le pepa palasitika o le faʻatumuina masini e faʻatumu ai le faiga o faʻavae, ma o le CIP o loʻo maua ai le suavai o le faʻapipiʻi o le sikaina o le suauʻu. O le faʻagaioiina o vaega o le TOBE Luga masini e fesoʻotaʻi ma le oloa i le taimi o gaosiga o gaioiga, pei o Piston pamu, etc., o le a feoaʻi atoatoa o le faʻasologa o vaega o loʻo faʻamamaina atoa.

4. O le Playoting Paipe mo le faʻamamaina o le suavai e toe foʻi mai i le Coupon Cip System o le saoasaoa o le saoasaoa o le saoasaoa (o le pamu toe faʻafoi o le sapalai)

5. PASTIC TUBU Sealing masini e mafai ona nofoia le faʻamamaina ma le faʻamaʻi o le tagata faʻatau e tusa ai ma le tagata faʻatau manaoga, ma o le faʻamamaina uma ma le faʻamoemoe o loʻo faʻatulagaina i le CIP Station

6. Parakalafa o le maualuga saoasaoa tibe tumu masini e pei o le maualuga saoasaoa tapulaa. O le vevela, o le faʻamalosi, tafe fua ma taimi o le cip o le taamilosaga e mafai ona seti e le cip couption e tusa ma manaʻoga o tagata faʻatau.

7. O le faʻatumu o numera o le palasitika tube faʻatumu masini e mafai foi ona vave tuʻuina atu mai le pamu o loʻo faʻamamaina.

8.Faaʻomia e manaʻomia le saoasaoa o le sipai maualuga faʻatumu masini o le 2T / h poʻo luga

O le saoasaoa o le sipi sili ona faʻatumuina masini o loʻo faʻaaogaina robots e fafaga ai tubes (15x2 tubes na ave i laina faʻalua taimi, 9-12 taimi / minute):

E tusa ai ma le Polokalama Polokalama, o le saoasaoa saoasaoa o le saoasaoa o masini e lua o laina e lua i le pito i luga o le kapeta. mafai ona aveʻeseina mo le faʻamamaina ma le faʻamaʻi poʻo le faʻateʻaina i le hydrogen peroxide pe a taofi le maualuga tele o le saoasaoa o le pupu

O le kalama e iloa ai pe i ai se tupaleft i le tamailima o le robot e le i faʻaoʻo atu i totonu o le inisi le ipu, ma faʻagaioi ona o le ulu o le tamailima.

Lfc4002 O le maualuga tele saoasaoa tibe tumu masini ei ai ni lelei aoga:

a. Puleaina o le System: O le saoasaoa saoasaoa o le faʻatumuina o masini e paʻi i le kinmen system scrend scrend slipleller, o le galuega atoa o le pasi O le pisapisao e itiiti ifo i le 75 decibels.

e. Faasino tuatusi: Faʻatumu masini faʻaaogaina se service system o le son starter stap o le saoasaoa o le mea e faʻatumu ai

i. Cup Chasin Taiala Taavale: O le Tatala Taofia le faʻatupeina o masini vaetamaina e fa-faʻatulagaina ma le fa o le faʻavasegaina o le saoasaoa

o e. Tuʻufaʻatasiga o Nofoaga: Pa puipui o le palasitika faʻatumu ma le masini faʻamau e i ai le paʻu o le faʻamamaina, o le ki o loʻo tulaʻi mai ai le paʻu.

u. Tatala pusa faʻatulagaina: Otometi tibe faʻatumu masini faʻaaogaina faʻalua-vaega felauaiga. O le paipa lea e feaveaʻi i luga o le pito i luga o vaega, o loʻo iai i luga o le auala tele, ma o le pusa gaogao ua toe faafoi i le vaega maualalo.

f. O le uta uta metotia: Robot poʻo le kilone utaina masini ulufale i luga o ato, ma mafai ona teuina 3000-4000 tupe i taimi uma.

l. Servo Custockmarking: O le lanu lanu uaina e puʻeina ai le taua, lapoa malosi manumalo manumalo, saoasaoa tele ma le mautu.

i. Servo faʻatumu: Otometi Taobe Faʻatumuina masini o loʻo iai le taimi atoa-laina servo drive ma tumu i luga o le pamu o le tino, lea

J. Alminitum Tube Clompting ma FloThening: O le patipati ma le faʻatamala o le sikaina o le faʻapipiʻi masini o le scour-cype clompting air i totonu o le paipa. suia i se siʻomaga o loʻo tatagiina ma mafolafola le masini, o le pefu-leai se pefu ma aloese mai le taʻavale kesi i totonu o le paipa.

k. Alminim Tabe Til Faʻamaumauga: Pe a faʻamaufaʻailoga le ube siusiu, o le faʻapipiʻi ma fetuʻutuʻutuʻu ma fetuʻutuuina o loʻo faʻaaogaina le laina o laina) gaioiga. E sili ona talafeagai lea mo le tolu-piiliti solo.

l. Faʻatulagaina masini: O le servo e faʻailoa mai ai le auala e fa ma ua i ai se teteʻe galuega.

o. Synchronous Conveying: Servo Intertevenved Workvenve, vavae ese le mautonu, lelei synchronization.

i. O le faʻamalosiʻau o le HPPP

Q. I luga ole laiga: E mafai ona faʻamamaina i luga o le initaneti poʻo fafo.

Polokalame Faapitoa

- Tubes faʻatumu masini masini autu masini faʻapitoa

| No | tulaga tau | tautinoga | |

| Tabe faamatalaga (MM) | Lapoa 13 ~ 30, umi 60 ~ 250 |

| |

| Valivali faʻailoga tulaga (mm) | ± 1.0 |

| |

| Faatumuina o le malosi (ml) | 1.5 ~ 200 (feiloai 5G-50G faʻamatalaga faʻapitoa, faʻapitoa faʻapitoa ma tele e tusa ai ma ituaiga ma tekonolosi) |

| |

| Faatumu le sao (%) | ≤ ± 0.5 |

| |

| Faamau | Lua-lafu, tolu-ato, ma nofoa-o lo o avanoa. |

| |

| Oloa Taualoa | 250-300 faagaau i le minute |

| |

| Fetaui lelei | Aluminum Paipe Place Paice Apaminim Plapa Paipa Paipa |

| |

| Malosiaga taumafaina (kw) | faagaau o le ie puipui | 35 |

|

| Ropota | 10 |

| |

| Mana | 380V 50hz |

| |

| ea o le ea | 0.6MPA |

| |

| Air taumafaina (m3/ H) | 20 ~ 30 |

| |

| Auina atu le faasologa | (Faʻaulufale mai mai Italia) Repar Synchronous Conlt Type (Servo drive) |

| |

| Tuatusi Fesuiaiga | Malo atoa tautua |

| |

| tele (mm) | Umi 3700 lautele 2000 maualuga 2500 |

| |

| Aofai mamafa (kg) | 4500 | ||

Smart zhiting e tele tagata faigaluega faapolofesa, o ai e mafai ona mamanuinaTubes faatumuina masiniE tusa ai ma manaʻoga moni o tagata faʻatau

Faʻamolemole faʻafesoʻotaʻi mai matou mo se mea saoloto @olspp +8615800211936

Faʻatumu ma le faʻapipiʻiina o masini masini faʻa-galuega faʻataʻitaʻi

1. FAʻAMATALAGA FAʻAALIGA: (UR) muamua, o le tuʻufaʻatasia o aʻoaʻoga o le ai ai le faʻaaogaina o manaʻoga o le tagata faʻatau, o oloa manaʻomia ma isi faʻamatalaga autu. O auiliiliga o manaʻoga, ia mautinoa o le faʻaogaina o masini e mafai ona faʻamalieina ai manaʻoga moni o tagata faʻatau.

2. Fuafuaga Fuafua: faʻavae iuga o le manaʻoga manaʻomia, e atiaʻe e le kamupani faʻasolopito faʻagaumauina o se auiliiliga o le Fuafuaga Ausepi. O le fuafuaga fuafuaga o le a aofia ai le fausaga faʻavae o le masini, faʻatonutonu faiga faʻavae, faʻagaoioiga tafega mamanu, ma isi

3. Faʻapitoa gaosiga: A maeʻa le fuafuaga o le fuafuaga, o le Ofisa Resitala Faʻalapotopotoga o le a amataina galuega gaosi. O le a latou faʻaaogaina mea maualuluga ma le tulaga e tusa ai ma manaʻoga o le fuafuaga fuafuaina e gaosia le faʻatumuina ma le faʻamaufaʻailoga e fetaui ma tagata faʻatau tagata.

4. Faʻapipiʻiina ma debugging: A maeʻa le gaosiga o kamupani, o le United Service Comminger o le a auina atu ni tomai faapolofesa i le nofoaga o tagata faʻatau mo le faʻapipiʻiina ma le faʻasaina. I le taimi o le faʻapipiʻiina ma le faʻatulagaina o gaioiga, o aʻoaʻoga o le a taʻitaʻia ai asiasiga ma suʻega i le masini ina ia mautinoa e mafai ona faʻagaioia manaʻoga a le tagata faʻatau. Saunia le gaʻo ma le Sat Services

5. Tomaitai Aʻoaʻoga: Ina ia mautinoa e mafai e tagata faʻatau ona faʻaaogaina le faʻaaogaina ma le faʻamau masini, o le a maua ai foi auaunaga faʻapitoa (pei o le faʻasaoina i le fale gaosi). Le aʻoaʻoga anotusi e aofia ai taimi faigaluega faʻamalosi metotia, taulimaina metotia, faʻafitauli metotia, ma isi. E ala i toleniga, e mafai e tagata faʻatau ona sili atu le talitonuina o tomai o le faʻaaogaina o le masini ma faʻaleleia atili le faia o galuega.

6. Ina ua maeʻa le tautua - O le matou tautua tautua faʻapitoa o le a saunia foi sili atu i se taimi pe a maeʻa le tautua. Afai e fetaiaʻi tagata faʻatau i ni faʻafitauli poʻo ni manaʻoga faʻapitoa i le faʻaaogaina, e mafai ona latou faʻafesoʻotaʻi le tautua tautua i soʻo se taimi e mauaina ai le fesoasoani ma le lagolago.

Vaa Metotia: e ala ile uta ma le ea

Taimi o le faaooina: 30 aso faigaluega

1.Tube faʻatumu masini @ 360pcs / minute:2. Tapu e faʻatumu masini @ 280cs / minute:3. Tapunia faʻatumu masini @ 200cs / minute4.Tebe faʻatumu masini @ 180cs / minute:5. Tabe faʻatumu masini @ 150cs / minute:6. Tapu e faʻatumu masini @ 120cs / minute7. Tabe faʻatumu masini @ 80cs / minute8. Tapunia faʻatumu masini @ 60cs / minute

Q 1.O le a lau paipa mea (palasitika, aluminum, comsosite tube. Abl Tube)

Tali, Tabe Mea o le a mafua ai le faʻamaufaʻailoga o le faʻaaogaina o le faʻaaogaina o le pube holer, matou te ofoina atu i totonu o le seleseleina o le vevela, vevela, maualuga mafuaʻaga o le faʻasoasoaina o auala

Q2, o le a lau paipa faʻatumu le agavaʻa ma le saʻo

Tali: Tabe Faatumuina le mafai ona avea ma manaʻoga o le a taʻitaʻia ai le tele o masini

Q3, o le a lau mea e tupu ai

Tali: E fia ni fasi e te manaʻo ai i le itula. O le a taʻitaʻia le tele o le faʻatumuina o auupega, matou te ofoina atu le tasi lua tolu ono ono faʻatumu ni au faʻatau mo le matou tagata faatau ma le galuega / minute / minute / minute / minute / minute / minute / minute / minute / minute / minute / minute

Q4, o le a le faatumuina o mea dynamic vircosity?

Tali: O le faʻatumu o mea e mafua ai ona avea le taʻiala o le faʻatulafonoina, matou te ofoina atu e pei o le faʻatumuina o le servo system

Q5, o le a le faatumuina o le vevela

Tali: O le faʻateleina o le faʻatumu o le vevela o le a manaʻomia ni eseesega o le hopper (pei o le peleue hopper, faʻafefeteina, vevela pulea faiga, tulaga o le ea ma isi)

Q6: O le a le mea o lo o foliga foliga

Tali: Matou te ofoina atu faʻapitoa silil foliga, 3D masani foliga mo le faʻamaufaʻailoga

Q7: E manaʻomia e le masini le CIP mama

Tali: O le CIP o loʻo i ai le auala tele o loʻo aofia ai tane o Amis, Alkali, o tane, o le acid orks, o le amo orks, o le artictic stactors, o le armact scress stactors ma prprass.

O le CIP mama faiga o le a fausia ni tupe faʻaalu faʻaopopo, faʻataulaitu i le toetoe lava o meaʻai uma, bealras ma vailaʻau faitotoʻa

Oloa vaega

-

Imeli

-

Telefoni

-

Pito i luga

0086 15800211936

0086 15800211936