Reasonable price Medicine Cartoning Machine - Horizontal Cartoning Machine for Cosmetic food,medicine,soap cosmetics packing – Smart ZhiTong

Reasonable price Medicine Cartoning Machine - Horizontal Cartoning Machine for Cosmetic food,medicine,soap cosmetics packing – Smart ZhiTong Detail:

Product Detail

◐ Automatic cartoners adopts PLC to control the photoelectricity to monitor the movement of each part, and automatically rejects unqualified items during operation. If there is an abnormality, it can automatically stop and display the reason, so as to eliminate the fault in time. Its hot melt device or other equipment is used in conjunction to form a complete production line

◐ Automatic cartoners adopts automatic opening (suction) boxes, folding instructions, blanking, feeding, batch numbering, box sealing, detecting and rejecting waste, etc. The operation is stable and the noise is low

◐ Cosmetic Cartoning Machine Adopt international well-known brand electrical components, with stable and reliable performance

◐ Functions of Cosmetic Cartoning Machine such as fault display, alarm and finished product counting, which is convenient for maintenance and troubleshooting

◐ Automatic cartoners has Various automatic feeders and conveying mechanisms can be designed according to customer requirements

◐ The automatic shutdown function of Cosmetic Cartoning Machine overload is adopted to ensure the safety of human and machine

◐ Optional hot-melt glue machine can be used to seal with hot-melt glue or design a hot-melt glue brushing device for Cosmetic Cartoning Machine

◐ Ointment Cartoning Machine has Various automatic feeders and box feeding systems can be designed according to the packaging requirements

◐ When there is no product or the product is not in place, the machine will idle without pushing the product. When the product is restored to supply, Cosmetic Cartoning Machine will automatically run. When the product is in the box, it will automatically stop and the main drive motor overload protection device

◐ Ointment Cartoning Machine Can design various automatic feeders and cartoning systems according to the requirements of packaging materials

◐ The photoelectric eye of Ointment Cartoning Machine automatic detection and tracking system is adopted, and there is no product without suction box, which saves the packaging materials to the maximum

◐ Ointment Cartoning Machine no need to replace the mold to replace the specification, and it can be realized only by adjustment

Technical parameter

NO.

ITEM

DATA

1

speed/capacity

100-120 carton/minute

2

machine dimension

3300×1550×1560

3

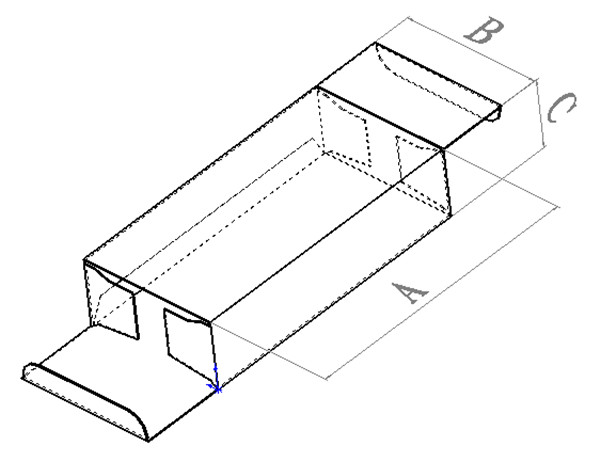

carton dimension range

minimum 45×20×14mm

maximum 250×150×120mm

4

carton material request

white cardboard 250-350g/m2

gray cardboard 300-400g/ m2

5

compressed air pressure/ air consumption

≥0.6Mpa/≤0.3m3 minute

6

main powder

1.5KW

7

main motor power

1.5KW

8

machine weight

(approx.) 1000Kg

Application field

Bottle Cartoning is suitable for medicine aluminum-plastic plates, round bottles, heterosexual bottles, food, school supplies, health products, toys, cosmetics, auto parts, toothpaste, paper towels, office supplies, hardware, household paper, poker, etc. and similar items It can automatically complete the folding of the manual, the opening of the carton, the boxing of the items, the printing of the batch number, and the sealing of the box.

Smart zhitong has many professional designers, who can design Cartoning Machinery according to the actual needs of customers

Please contact us for free help @whatspp +8615800211936

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for Reasonable price Medicine Cartoning Machine - Horizontal Cartoning Machine for Cosmetic food,medicine,soap cosmetics packing – Smart ZhiTong , The product will supply to all over the world, such as: belarus, Pakistan, Zambia, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the high quality and long-term cooperation. Our company upholds the spirit of innovation, harmony, team work and sharing, trails, pragmatic progress. Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

Products categories

-

E-mail

-

Phone

-

Top

0086 15800211936

0086 15800211936