Plastic Tube Filling and Sealing Machine (40 60 80 tubes/min)

Plastic tube filling and sealing machine is fully automatic Turning table type has become in the cosmetic, personal care, household, and chemical industries. For small and middle size manufacturing companies Plastic Tube Filling Machine is suitable for plastic tubes & aluminum tubes for the filling and sealer machine process ,no other tube filler t can match the out-performance and quality at this price level. plastic tube machine can run up to 40 60 80 tubes per minute using inner hot air sealing for both plastic and laminate tubes. Aluminum tube filling with double-fold and saddle-fold crimping is also available within the same machine. Quickly changeover plastic tube holder size and easy cleaning, tube filling sealing machines meet the needs of contract manufacturing and brand companies of all sizes and GMP requirements

PRODUCT DETAIL

| Model no | Nf-40 | NF-60 | NF-80 | NF-120 |

| Tube material | Plastic aluminum tubes .composite ABL laminate tubes | |||

| Station no | 9 | 9 | 12 | 36 |

| Tube diameter | φ13-φ60 mm | |||

| Tube length(mm) | 50-220 adjustable | |||

| viscous products | Viscosity less than 100000cpcream gel ointment toothpaste paste food sauce and pharmaceutical, daily chemical, fine chemical | |||

| capacity(mm) | 5-250ml adjustable | |||

| Filling volume(optional) | A:6-60ml, B:10-120ml, C:25-250ml, D:50-500ml (Customer made available) | |||

| Filling accuracy | ≤±1% | |||

| tubes per minute | 20-25 | 30 | 40-75 | 80-100 |

| Hopper Volume: | 30litre | 40litre | 45litre | 50 litre |

| air supply | 0.55-0.65Mpa 30 m3/min | 340 m3/min | ||

| motor power | 2Kw(380V/220V 50Hz) | 3kw | 5kw | |

| heating power | 3Kw | 6kw | ||

| size(mm) | 1200×800×1200mm | 2620×1020×1980 | 2720×1020×1980 | 3020×110×1980 |

| weight (kg) | 600 | 800 | 1300 | 1800 |

Plastic tube filling and sealing machine features:

1.Large Touch Screen size HMI Siemens PLC Preset tube sealing settings

2.Program Control automatic tube filling dosing device Automatic Tube loading and Discharge device

3.No Tube No Fill function for safety design Sealing mothed inner hot Air Sealing (set up to 600 Celsius)

4.Adopted sick or banner for automatic Tube Orientation Single Filling Nozzle with air blow self-clean tube function

5.Rapid replacement tube size seats ,easy cleaning plastic tube filling and sealing machine adopted high-quality SS316 Stainless Steel for Contact Parts

6.Automatic Cassette Tube Feeding and inclined hanging tube box for option Bottom-up Filling with drip-proof filling nozzle(high quality ss 316)

Main configuration

|

Model no |

NF-40 |

NF-60 |

NF-80 |

|

Configuration Standard |

Technical Parameters |

||

| Infrastructure | |||

| Main Machine Landing Area | (about)2m2 | 4 m2 | 6 m2 |

| Main Machine Working Area | (about)8m2 | 10 m2 | 12 m2 |

| Water Chiller Landing Area | (about)1m2 | ||

| Water Chiller Working Area | (about)2m2 | ||

| Whole Machine (L×W×H) | 1200×800×1200mm | 2620×1020×1980 | 2720×1020×1980 |

| Integrated Structure | Union mode | ||

| Weight | (about)650Kg | 850KG | 1100KG |

| Machine case body | |||

| Body Material | stainless steel SS304 | ||

| Opening Mode of Safety Guard | Handle Door | ||

| Safety Guard Material | Organic Glass | ||

| Frame Below Platform | High-quality Stainless Steel | ||

| Body Shape | Square-shape | ||

| Power, Main Motor etc. | |||

| Power Supply | 50—60hz /380V 3P+Grounded line | ||

| Main Motor | 1.1KW | 3kw | 3kw |

| Hot Air Generator | 3KW | ||

| Water Chiller | 1.9KW | ||

| Jacket barrel heating power | 1.5 KW | 2.0KW | 2.0KW |

| Jacket barrel blending power | 0.18 KW | 0.2KW | 0.2KW |

| Tubes per minute (output capacity) | |||

| tubes per minute | 20-35 tubes/min/max | 35—55 tubes | 40—75tubes |

| Filling Range | Plastic/ aluminum tube 3-250 gram | ||

| Suitable Tube Length | Plastic/ aluminum tubes 50-210mm | ||

| Suitable Tube Diameter | Plastic/laminated aluminum tubes 13-50mm | ||

| Pressing Device | |||

| Pressing Guiding Main Component | CHINA | ||

| Pneumatic Control System | |||

| Low Voltage Protection | CHINA | ||

| Pneumatic Component | AIRTAC | ||

| Working Pressure | 0.5-0.7MPa | ||

| Compressed Air Consumption | 1.1m³/min | 3m³/min | 5m³/min |

| Electrical Control System | |||

| Control Mode | PLC+Touch Screen | ||

| PLC | Siemens | ||

| Frequency inverter | TAIDA | ||

| Touch Screen | WENVIEW | ||

| Coder | OMRON | ||

| Filling detect Photo electric cell | no | no | AUTONICS |

| Total Power Switch etc. | CHINT | ||

| Color Code Sensor | Banner or sick | ||

| Hot Air Generator | LEISTER (Switzerland) | ||

| Suitable Packing Material & Other Devices | |||

| Suitable tube Material | Aluminum-plastic composite tubes and Plastic tube aluminum tubes | ||

| Obliquely Hanging Lining-up Tube Storehouse | Loading tube Speed Adjustable | ||

| Material contacted with filling material | high quality 316L Stainless Steel | ||

| Jacket layer hopper device | Temp. Setting according to material and filling demand

Hopper material: high-quality stainless steel SS 316 |

||

| Jacket layer stirring device | material mixing, it remains fixed in the hopper

high quality stainless steel SS 316 |

||

| Auto stamping device | Single side or double sides printing at the end of seal tube. | ||

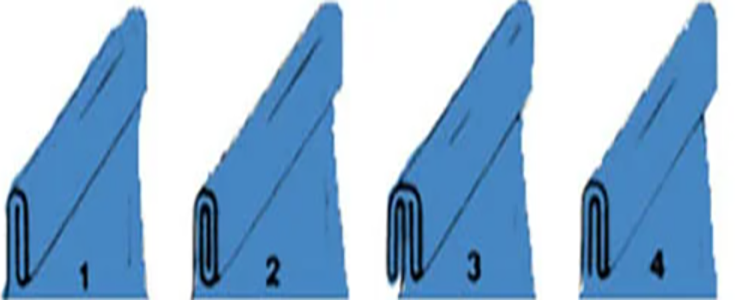

Tube Tail Trimming Shape

For plastic tube Tail Trimming Shape

For aluminum tubes Tail Trimming Shape

Application field

Fully plastic tube filling and sealing machine adopts closed filling paste and liquid, sealing without leakage, filling weight and capacity consistency, filling, sealing and printing can be completed in one time, suitable for the pharmaceutical, daily chemical, food, chemical, and other fields of product packaging. Such as ointment, hair dye, toothpaste, shoe polish, adhesive, AB glue, epoxy glue, chloroprene glue, and other materials for filling and sealing. It is an ideal, practical, and economical filling equipment for pharmaceutical, daily chemical, fine chemical, and other industries.

Why choice us

Choosing our Plastic Tube Filling and Sealing Machine can ensure that your production process is more efficient, stable, in line with industry standards based on the following core advantages and features:

1. Efficient production capacity for Plastic Tube Filling Machine design

a. High-capacity design: Our machines are designed with efficient production capabilities. For example, some models can reach a production speed of 60-250 pieces per minute for options, significantly improving production efficiency.

b. Quick adjustment and changeover: The machine can be easily adjusted to suit plastic tubes of different specifications and sizes, reducing changeover time and production costs.

2. Precision filling technology

a. High-precision filling: Using advanced filling technology, such as volume pump filling or the most advanced ceramic pump, to ensure that the filling accuracy is within ±1%, fully meeting the high-precision filling needs.

b. A variety of filling volumes are available: Plastic Tube Filling Machine supports a variety of filling volume settings, such as 5-25 grams, 15-15 grams, 30-200 grams, etc. The customized tube filling machine can reach 350 grams to flexibly adapt to the filling needs of different products.

3. Advanced sealing technology to Plastic Tube Filling Machine

a. Ultrasonic welding sealing: some models of plastic tube filling machine use ultrasonic welding technology to ensure that the tube tail is firmly sealed and beautiful without leakage risk。

b. Hot air heating and sealing: Another machine model uses hot air heating for internal sealing, combined with circulating water cooling to ensure sealing quality

c. High-frequency sealing technology: Other machines use high-frequency heating for internal sealing to meet the needs of high-speed machines.

Smart zhitong has many professional designers, who can design Tubes Filling Machine according to the actual needs of customers

Please contact us for free help @whatspp +8615800211936

Products categories

-

E-mail

-

Phone

-

Top

0086 15800211936

0086 15800211936