Plastic Tube Filling and Sealing Machine(60 80 tubes/min)

Rotary plasitc tube filling machine for plastic tube filling and sealing machine is a professional filling system for packing machine for plastic tube filling and sealing. widely used in the packaging of paste, liquid and other products in the cosmetics, medicine, food and other industries. The machine can handle metal plastic aluminum tube packing machine. The following are some main features and functions about Plastic Tube Filling Machine:

1. This type rotary tubes machine can drives plastic tube and aluminum tubes to perform fully automatic continuous filling and sealing machine operation through the high quality divider turntable driven by the control with PLC based motor. There are 8-12 stations on the turntable, different stations are equipped with corresponding tube filling and tube sealing mechanisms to achieve efficient automatic production. According to the set filling volume, the material is accurately filled into the plastic tube and aluminum tubes and ensures accurate filling. The tube filling and sealing machine has safety functions such as overload protection and material shortage alarm to ensure the safety and reliability of the operation process. Through PLC and touch screen control panel, the fully automatic tube filling and sealing process is realized and the coding is completed. The Plasitc tube filler reduces the difficulty and labor intensity of manual operation.

PRODUCT DETAIL

| Model no | NF-60(A B) | NF-80(A B) |

| Tube Tail Trimming method | Inner heating and Mechanical mechanism | |

| Tube material | Plastic ,aluminum tubes .composite ABL laminate tubes | |

| Station Rotary Indexing | 9 | 12 |

| Tube dia(MM) | φ13-φ60 | φ13-φ60 |

| Tube extend (mm) | 50-220 adjustable | |

| Suitable filling product | cream gel ointment toothpaste paste food sauce and pharmaceutical, daily chemical, fine chemical | |

| Filling capacity (mm) | 5-250ml adjustable | |

| Tube capacity | A:6-60ml, B:10-120ml, C:25-250ml, D:50-500ml (Customer made available) | |

| Filling accuracy | ≤±1% | |

| Tubes per minute | 45-55 tubes per minute | 40-75 tubes per minute |

| Hopper capacity: | 40litre | 55litre |

| Air Specification | 0.55-0.65Mpa 0.1 m3/min | |

| motor power | 2Kw(380V/220V 3-phase 50—60HZ) | 3Kw(380V/220V 3-phase 50-60hz) |

| heating power | 3Kw | |

| Dimension (LXWXH mm) | 1900×1020×1980 | 2720×1020×1980 |

| Net weight (kg) | 800 | 1300 |

2. Plastic Tube Filling Machine adopts the tube lifting machine is mechatronic, the whole machine has a reasonable design compacted structure, controlled by PLC, and the height of the tube in the tube groove of the tail sealing machine is monitored by the speed regulating device and the photoeye switch, so as to achieve the synchronization of lifting and tail sealing machine, with a high degree of automation.

3.To ensure that the tube is not contaminated during the lifting process, the material of the part of the machine that contacts the tube is 304 stainless steel, and the contact surface is fully polished with high quality SS 316 ,machine can meet the lifting of various types of tube and is one of the advanced metal, composite (aluminum-plastic) and tube lifting equipment.

4. When changing the lifting of tubes of different diameters, the mechanism adjustment is convenient and reliable. The conveying and lifting are stable and uninterrupted. When working at a speed of 100 tubes per minute, the lifting is stable and uninterrupted, the machinery is stable and noiseless, and there is no tube jamming.

Filling and sealing machine feature

1.12 inch Touch Screen size HMI Siemens PLC Preset tube sealing settings device

2, Hot air exhaust duct design ensures a safe working environment tube sealers has No tube, no filling function to achieve safety

3.Programmable control automatic tube filling metering Inner hot Air Sealing(LEISTER) (set up to 600 Celsius)

4.Filling Nozzle with air blow self-clean tube function

5.Quick change tube sizes holder, easy cleaning Plastic Tube Filling Machine use SS316 Stainless Steel for material Contact Parts

6. Bottom up Filling with drip-proof filling nozzle(high quality ss 316) Sick or banner for Tube auto sensor tube position Stepper motor adjustment Orientation

Loading Cassette automatically loads and seals plastic tubes, improving production efficiency and saving human cost

Main configuration

|

NF-60 |

NF-80 |

|

|

Configuration Standard |

Technical Parameters |

|

| Infrastructure | ||

| Machine floor space | 5m2 | 7 m2 |

| Machine Working space | 10 m2 | 12 m2 |

| Chiller floor Area | (about)1m2 | |

| Chiller Working floor area | (about)2m2 | |

| Machine size(L×W×H) | 2620×1020×1980 | 2720×1020×1980 |

| Weight | 850KG | 1100KG |

| Host chassis | ||

| Frame Material | stainless steel SS304 | |

| Safety door Guard | Handle Door | |

| Safety door Material | Organic Glass | |

| Platform | high quality Stainless Steel | |

| Host Shape | Square-shape | |

| Power, Main Motor etc. | ||

| Power specification | 380V 240v 3P 50-60hz/ | |

| Main Motor | 3kw | 3kw |

| Hot Air Generator Consumption | 3KW(LEISTER (Switzerland)) | |

| Water Chiller Consumption | 1.9KW | |

| Jacket hopper power Consumption | 2.0KW | 2.0KW |

| Jacket hopper motor power | 0.18 KW

|

0.2KW |

| Tubes per minute (output capacity) | ||

| tubes per minute | 35--55 | 40--75 |

| Filling Range | Plastic/ aluminum tube 3-250ml | |

| Suitable Tubes Length | Plastic/ aluminum ABL tubes 50-210mm | |

| Suitable Tubes Diameter | Plastic/laminated ABL tubes 13-50mm | |

| Pressing Device | ||

| Pressing Guiding Main Component | CHINA | |

| Pneumatic Control System | ||

| Low Voltage Protection | CHINA | |

| Pneumatic Component | AIRTAC | |

| Working Pressure | 0.5-0.7MPa | |

| Air Consumption | 30m³/min | 50m³/min |

| Electrical Control System | ||

| Control Mode | PLC+Touch Screen (control with plc based) | |

| PLC | Siemens | |

| Frequency inverter | TAIDA | |

| Touch Screen | Siemens | |

| En Coder | OMRON | |

| Filling detect Photo electric cell | no | AUTONICS |

| Total Power Switch etc. | CHINT | |

| Color Code Sensor | Banner or sick | |

| Hot Air Generator | LEISTER (Switzerland) | |

| Suitable Packing Material & Other Devices (option) | ||

| Suitable tube Material | Aluminum-plastic composite tube and Plastic tube aluminum tubes | |

| Tube hopper (Loading Cassette) | Transfer tubes rate Adjustable | |

| Material contacting with filling material | high quality 316L Stainless Steel | |

| Jacket layer hopper device | Temp. Setting according to material and filling demand

Hopper material: high quality stainless steel SS 316 |

|

| Jacket layer mixer | material mixing, it remains fixed in hopper

high quality stainless steel SS 316 |

|

| Auto stamping device | Single or double sides encode at tube tails | |

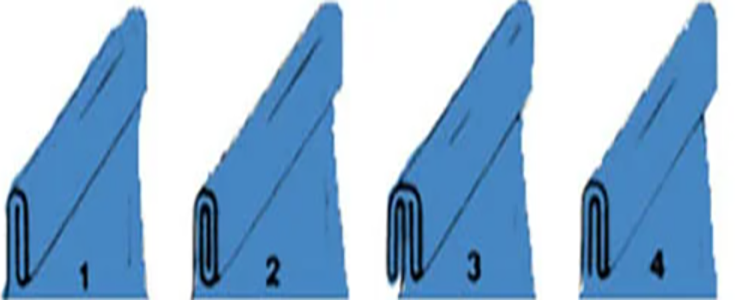

Tube Tail Trimming Shape

For plastic tube Tail Trimming Shape

For aluminum tubes Tail Trimming Shape

plastic tube sealing ABL tubes sealing device

aluminum tubes sealing device

Why choice us

Zhitong is one of leading tube filling machine manufacturers over 15 years focus on the tube filling machinery ,the tube filling machine manufacturer for design development and making sale company mainly focusing on plastic tube filling and sealing machine rotary tube filling machine and offer packing solution for our customers

1. Reasonable design, simple operation, suitable for multiple sets of moulds, quickly replacement.

2. Full-featured, versatile, suitable for all kinds of plastic pipe Aluminum-plastic pipe

3. Using PLC system to control the standard, the color mark detection is more accurate and the trial life is long.

4. The material of the contact part with the material is 316 stainless steel, which meets the GMP standard.

5. The connection of each component is in the form of quick-loading, which is convenient for disassembly and cleaning.

6. Optional heating and heat preservation mixing barrel is convenient for viscous and smooth filling.

7. Use high-quality pneumatic components to ensure more stable operation of the machine

Smart zhitong has many professional designers, who can design Tubes Filling Machine according to the actual needs of customers

Please contact us for free help @whatspp +8615800211936

Products categories

-

E-mail

-

Phone

-

Top

0086 15800211936

0086 15800211936