Machubu odzaza makina opangira pulasitiki ndi aluminium chubu (mpaka 320 ppm)

Kufotokozera mwachidule za kuthamanga kwa chubu chodzaza:

1.

2,Kuthamanga kwambiri chubu chojambula pamakina kuli pa liwiro lalitali 320 chubu chodzaza pamphindi pa mphindi 280 ndikudzaza mphindi 280

2. Dongosolo la Jog limagwira ntchito mothamanga kwambiri

3. Nambala yayikulu (HMI) kuti musinthe makonda onse opanga diamer

4. Panel Panel imawonetsa kuchuluka kopanga ndi mawonekedwe opanga kuti muwunikire

5. Malinga ndi makasitomala zosowa, makina a chubu ali ndi mapangidwe angapo a chubu cha chubu chofalikira ku PLC

6 .. The Rusting chumba lodzaza ndi makina oyendetsa makina amatha kukhazikitsa ntchito

7 .. Makina okwanira a chubu amagwiritsa ntchito gulu la opaleshoni yoyendetsedwa ndi magawo atatu osiyanasiyana oyang'anira oyang'anira

8. Makina otchinga a chubu ma pinki pakati pa makabatini yamagetsi ndi makina ogwiritsira ntchito zotsekeka zotsekeka, zingwe zimalowa kuchokera pamwamba pa makinawo pamlingo wapamwamba.

M'tsogolomu, dongosolo loyendetsa bwino chubu chodzaza chubu limatha kugwiritsa ntchito siemens yopindulitsa kusamutsa deta ndikulumikizana ndi ma mes.

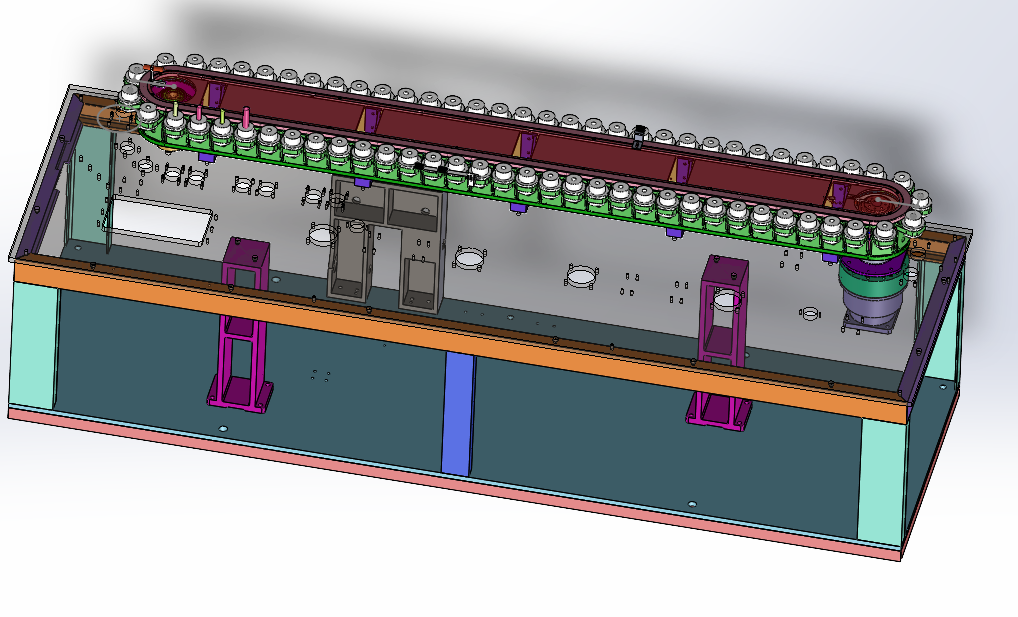

Makina othamanga kwambiri chubu chodzaza ndi pulasitinu ndi aluminium chubu

LFC4002 Hight Rusting chubu chodzaza Kodi kuthira kwa chubu kanayi ndi kusindikizidwa kwa chubu chokwanira-selco pulasitiki ma tuber osasinthika, kuthamanga kwa machubu opangidwa ndi aluminium Ma tubes / miniti, komanso njira yeniyeni yopanga bwino kwambiri kwa chubu ndi machubu / mphindi. Kudzaza kulondola ndi ≤ ± 0,5%. Gawo lamakina la aluminium limasindikizidwa ndi kusindikiza, aluminiyamu-pulasitiki osindikizidwa ndi mpweya wotentha kapena ukadaulo wothira pafupipafupi

Kuthamanga Kwambiri chubu Kudzaza Makina Kutsitsa Makina:

Makina othamanga kwambiri a chubu Zimatengera siteyi yolumikizira yolumikizirana yolumikizira, yotsutsa itatu yonyamula zikho zikho zikho zotsekemera, malo a 4kW servo detagn chubu choyendetsa chubu chonyamula chingwe. Makina othamanga kwambiri awa amatsimikiza kuthamanga kwambiri @ 320 chubu chodzaza pamphindi kapena kukhazikika kwa pulasitiki ya pulasitiki ndikunyamula

Kuthamanga kwambiri chubu chodzaza makina chubu chikho chojambulidwa chida chimakhala ndi zokutira zitatu, m'munsi ndi ku Show Steel Stoel. Zimbalangondo zitatu zogulira zimakhazikitsidwa pampando wa chubu, ndipo mapepala ofuula amasuntha molondola mu zogulitsa ndikuyendetsa machubu. Kudzaza unyolo sikuyenera kuvala nthawi yayitali. Palinso zimbalangondo ziwiri zapamwamba kwambiri komanso zotsika kwambiri zokhazikika pazikhomo zosinthira kukula kwa chubu kukula.

Makina othamanga kwambiri chubu, thumba la chubu chimangirira ndikukonza mipando ya chubu (kuyikapo mipando ya chubu (itatu-stoner, steel wowongolera) wina ndi mnzake. Lamba lokhotakhota kwa chubu chodzaza masiketi amayenda molingana ndi njira yotumizira yoyendetsera gudumu loyendetsa. Tube chikho chimayikidwa pa chubu chilichonse cha chubu. Kudzaza makina kumakhala ndi makapu 116 otsimikizira kuti makina amatha kuthamanga kwambiri 320 chubu / mphindi chubu chikho chimapangidwa ndi zinthu zowala kwambiri ndikukumana ndi zomwe amapanga.

Kuthamanga kwambiri chubu chodzaza ndi machira kumachitika powonjezera poyambira malire okhazikika pa gudumu la Torchquous, omwe ali ndi moyo wautali. Ngati unyolo wa chubu chakhazikika, cholumikizira chimakhala cholumikizidwa, kusinthana kwakumaku kumayambitsidwa, ndipo makinawo amasiya nthawi yomweyo ngakhale kuthamanga kwambiri

Kuthamanga kwambiri chubu chodzaza makina oyeretsa

1. Kuthamanga kwa chubu chambiri chodzaza makina ndi hopper zitha kutsukidwa zokha ndi malo otsekeka mu lop yotsekedwa nthawi yomweyo.

2. Asanayambe cip for a chubu chodzaza chubu cha chubu cha tube adayikidwa ndi ma cummy, kuyeretsa madzi apulating'ono olumikizidwa ndi chikho cholumikizidwa ndi kapu.

3. Mpira wotsikirako umayikidwa mu silinda, ndipo mtengo wopukutira umatulutsa woyeretsa pamkati mwa silinda. Makina ofunda apulati a pulasitiki amadzaza dongosolo lausotikisi, ndipo madzi oyeretsa a CIP amatha kufikira pamakina owuma kwambiri a chubu chambiri, mapaipi ndi zida zomwe zimakumana ndi malonda a pulasitiki. Magawo osunthira a chubu fillery makina omwe amakumana nawo mukamapanga, monga mapampu, akuluakulu, ndi zina.

4. Chitoliro cholumikizira chakumadzi choyeretsedwa kuti chibwezeretse makina a kasitomala othamanga kwambiri (pampu yobwerera sakuphatikizidwa pamawonekedwe)

5. Makina abulu apulasitiki amatha kuyeretsa ndi kutsuka mogwirizana ndi zosowa za kasitomala, ndipo kuyeretsa konse ndi kutsuka kumakonzedwa mu station ya CIP

6. Magawo a kuthamanga kwa chubu cha chubu chodzaza monga phala lalitali kwambiri. Kutentha, kupanikizika, kuchuluka kwa nthawi ndi nthawi ya kuzungulira kwa cip ikhoza kukhazikitsidwa ndi malo owerengera malinga malinga ndi zomwe makasitomala amafuna.

7. Nyimbo zodzaza za makina odzaza apula za pulasitiki zitha kusokonekera mwachangu kuchokera pampupoyi yoyeretsa.

Mitengo yamagalimoto imafuna kuti makina odzaza a chubu ikhale ndi 2t / h kapena pamwambapa

Makina othamanga a chubu

Malinga ndi pulogalamu yopanga, makina othamanga kwambiri a chubu amatulutsa mizere iwiri ya machubu ikhoza kusokonezedwa pakuyeretsa ndi kuyika magetsi kapena kuyika kachilombo ka hydrogen peroxide kupukusa khofi wothamanga kwambiri

Kukula kumazindikira ngati pali chubu cha robot chomwe sichinaikidwe mu chubu chikho, ndikuyambitsa makina oundana kuti achotse chubucho m'manja, kenako nkutenga chubu.

Makina othamanga a LFC4002 ali ndi makina otsatirawa:

a. Makina Olamulira: Makina othamanga kwambiri a chubu amatengera Science Streen ndi ku Japan purcect wowongolera, Servie Servied; Phokoso limakhala lochepera 75 Desibels.

b. Makina olemba: Kudzaza makina kumagwiritsa ntchito njira ya servo ngati njira ya makina othamanga, kutalika kokhazikika kwa chiwerengero cha pulasitiki

c. Stup Toun Railt Rail: Makina odzaza ndi ma chubu amatengera zojambula zinayi ndi zophatikizira zazitali zokuza, zotsatsa zolumikizira zikho zitatu

d. Kupatukana kwa madera: pulasitiki wodzaza ndi makina osindikizira ali ndi ntchito yoyeretsa, yopanga chubu ya Robot Shobe Kutsegula, Kudzaza, madera ena amalekanitsidwa malinga ndi zomwe GPJOT zimalekanitsa.

e. Bokosi la chubu likuikidwa: Makina odzaza chubu amatengera mayendedwe osanjikiza kawiri. Bokosi la chubu limayendetsedwa pamtunda wapamwamba, limakhazikika papulatifomu, ndipo bokosi lopanda kanthu limabwezedwa pamtunda wotsika.

f. Njira Yotsitsa: Robot kapena chubu Kutayika kumalowa m'machubu, ndipo amatha kusunga machubu 3000 nthawi zonse.

h. Serso benchmark yolimba: Chuma cha odwala Mark Chingwe chojambulidwa, chipongwe chachikulu cha torque chimayimitsa, liwiro lalitali komanso kukhazikika.

i. Serfa yodzaza: Makina a chubu chodzaza ndi mzere wa servo drive ndi pampompime yathunthu, yomwe sidzatopa.

J. Aluminium chubu polimbana ndi kuyamwa ndi makina owonera ndi chipangizo cha mchile chosindikizira. Anasintha kukhala makina ozungulira komanso njira yoyatsira, yomwe ndi yopanda fumbi ndikupewa kuyendetsa mpweya kulowa mu chubu.

k. Kusindikiza chubu cha aluminiyamu Kusindikiza kwa chubu: Kusindikiza mchira wa chubu, kukweza ndi kuzungulira kwa mzere wowongolera (koyambirira kwa mawonekedwe a Arc) osakoka chubu kumtunda. Izi ndizoyenera makamaka michira yamichisi atatu.

n. Chipangizo chobwezera: Servo imatulutsa chubu cha-njirayi ndipo imagwira ntchito yokana.

o. Kupereka kwa Snynchroous: Kuyenda kwa Servo kumodzi, kufalitsa kotukana, kuluma bwino.

p. Kupanikizika kwa Spipt: Kutengera njira yotsegulira mwachangu kwa chitoliro chogawa kuti mulumikizane ndi kudzazidwa.

Q. Paintaneti: imatha kutsukidwa pa intaneti kapena pa intaneti.

Ndondomeko yaukadaulo

- Machubu odzaza makina amagetsi zida zaluso zamaluso

| No | palamu | Ndemanga | |

| Tsitsi (mm) | Diameter 13 ~ 30, kutalika 60 ~ 250 |

| |

| Mtundu wa zilembo (mm) | ± 1.0 |

| |

| Kudzaza Mphamvu (ml) | 1.5 ~ 200 (kukumana ndi 5g-50G, zojambula zapadera monga zimatengera mitundu ndi ukadaulo) |

| |

| Kudzaza kulondola (%) | ≤ ± 0,5 |

| |

| Zingwe zosindikizira | Zida ziwiri, zokutira zitatu, ndi zikwangwani zowoneka bwino zilipo. |

| |

| Kutulutsa mphamvu | 250-300 chubu pamphindi |

| |

| Chubu choyenera | Aluminium pipe pulasitiki pip alminim pulasitiki chitoliro |

| |

| Kugwiritsa Ntchito Mphamvu (KW) | chubu cha filler | 35 |

|

| Loboti | 10 |

| |

| Mphamvu | 380v 50hz |

| |

| kupsinjika kwa mpweya | 0.6mm |

| |

| Kugwiritsa ntchito mpweya (m3/ h) | 20 ~ 30 |

| |

| Fomu Yapatali | (Yochokera ku Italy) Recher Synchroous Lal |

| |

| Njira Yogulitsa | Full Serviro drive |

| |

| kukula (mm) | Kutalika kwa 3700 Kutalika 2000 mpaka 2500 |

| |

| Kulemera kwathunthu (kg) | 4500 | ||

Smart Zhitong ali ndi akatswiri ambiri akatswiri, omwe angapangeMachubu odzaza makinaMalinga ndi zosowa zenizeni za makasitomala

Chonde funsani kuti muthandizire kwaulere @whatspp +8615800211936

Kudzaza ndi Kusindikiza Makina Ogwiritsira Ntchito Ntchito

1. Kufunafuna Kusanthula: Pakufunika kusanthula, onetsetsani kuti makina osinthika atha kukwaniritsa zosowa zenizeni za makasitomala.

2. Dongosolo la Kapangidwe: Kutengera zotsatira za kusanthula kumeneku, wopereka chithandizo wa chizolowezi adzapanga mapulani atsatanetsatane opangidwa mwatsatanetsatane. Dongosolo lopanga liphatikizira kapangidwe ka makina, kuwongolera kapangidwe ka dongosolo, kapangidwe kake kayendedwe kazinthu, etc.

3. Kupanga kokonzekera: Dongosolo la kapangidwe kake litatsimikiziridwa ndi kasitomala, Wopereka chithandizo wa chithandizo ayamba ntchito yopanga. Agwiritsa ntchito zida zapamwamba kwambiri komanso magawo osiyanasiyana mogwirizana ndi zomwe akufuna kupanga mapulani opangidwa ndi makina osindikizira omwe amakumana ndi zosowa za makasitomala.

4. Kukhazikitsa ndi Kupanga: Pambuyo popanga chithandizo chambiri, ogulitsa chithandizo amatumiza akatswiri opanga makasitomala kuti akhazikitse. Pakukhazikitsa ndi kutumiza kwa ntchito, matesani adzagwirira ntchito zoyeserera kwathunthu ndi mayeso pamakinawo kuti awonetsetse kuti amatha kugwira ntchito bwino ndikukwaniritsa zosowa za kasitomala. Perekani ma mafuta ndi miyeso

5. Ntchito zophunzitsira: Pofuna kuonetsetsa kuti makasitomala amatha kugwiritsa ntchito makina okwanira mwapadera, opereka chithandizo chautumiki chidzaperekanso ntchito zophunzitsira (monga kuwongolera mufakitale). Zophunzitsira zimaphatikizanso njira zamakina, njira zoyenera, njira zovuta, ndi zina zambiri. Kudzera mu maphunziro, makasitomala amatha kukhala ndi maluso ogwiritsa ntchito makinawo ndikusintha mphamvu).

6. Pambuyo pogulitsa: Wopereka chithandizo wathu amathandizanso kuthandizanso pambuyo pogulitsa. Ngati makasitomala akukumana ndi mavuto aliwonse kapena amafunikira thandizo laukadaulo pakagwiritsidwa ntchito, amatha kulumikizana ndi wopereka chithandizo nthawi iliyonse kuti athandizidwe ndi thandizo la panthawi yake.

Njira Yotumiza: Ndi katundu ndi mpweya

Nthawi Yoperekera: Masiku 30 ogwira ntchito

1.Tube yodzaza makina a @ 360pcs / mphindi:2. Makina odzaza @ 280cs / mphindi:3. Makina odzaza @ 200cs / mphindi4.Tube yodzaza makina @ 180cs / mphindi:5. Makina odzaza @ 150cs / mphindi:6. Makina odzaza @ 120cs / mphindi7. Makina odzaza @ 80cs / mphindi8. Makina odzaza @ 60cs / mphindi

Q 1.Kodi chitukuko chanu (pulasitiki, pulasitiki, aluminium, chubu chophatikizika. Abl chubu)

Yankho, Zinthu za chubu zidzayambitsa chipika cha chubu cha chubu cha chubu cha chubu, timapereka njira yopumira mkati, yothira kunja, kutentha, njira zotenthetsera ndi njira zopirira mchira

Q2, Kodi chubu chanu ndi chiani chokwanira komanso kulondola

Yankho: Tsitsani zodzaza ndi mphamvu zotsogola

Q3, Kodi chiyembekezo chanu ndi chiyani?

Yankho: Kodi mukufuna magawo angati pa ola limodzi. Zidzachititsa kuti anthu ambiri azidzadzaza kangating'ono, timapereka milungu isanu ndi iwiri yodzaza ndi makasitomala athu ndipo zotulukapo zimatha kufikira 360 ma PC / mphindi

Q4, Kodi kudzaza ma virukic ndi chiyani?

Yankho: Kudzaza mafayilo olimbitsa thupi kumadzaza kusankha dongosolo, timapereka monga chodzaza ndi katswiri

Q5, kodi kutentha kudzaza

Yankho: Kusiyana Kuzaza Kutentha Kufunika Kusakanikirana Kwambiri

Q6: Mchira

Yankho: Timapereka mawonekedwe apadera a mchira, mawonekedwe a 3d wamba pa kusindikiza mchira

Q7: Kodi makinawo amafunikira dongosolo loyenerera

Yankho: Njira yoyeretsa ya cip makamaka imakhala ndi akasinja a acidi, akasinja am'madzi, mapepu a alkali, amadzimadzi, acipe amadzimadzi, alkali amathandizira kuwongolera njira.

Dongosolo loyenerera la CIP lipange ndalama zowonjezera, zomwe zikufunika kwambiri pafupifupi chakudya, chakumwa komanso mafakitale a mankhwala a tube filler

Magulu a Zinthu

-

Imelo

-

Foni

-

Kumwamba

0086 15800211936

0086 15800211936