Plastic filling et signantes apparatus (LX LXXX tubi / min)

Plasitc Tube Filling Machina ad plastic tube filling et signantes apparatus est professional filling systema pro stipare apparatus ad plastic filling et signantes. late in packaging de crustulum, liquida et alia products in stibio, medicina, cibum et aliis industrias. Et apparatus can tractamus metallum plastic aluminium tubo sarcina apparatus. Et haec est quaedam principalis features et munera de plastic fistulae implens machina:

I. Hoc genus gyratorius tubere machina potest agitet plastic tubo et aluminium fistulae praestare pleneAutomatic continua saturitatem et signa apparatusOperatio per excelsum qualis divisor turntable repulsi per imperium cum plc secundum motricium. Sunt 8-12 statio in turntable, diversis statio sunt instructa cum correspondentes fille implens et tubum signantes machinationes ad consequi efficientis ipso productio. Secundum ad set implens volumine, in materia est verius repleti in plastic fistulam et aluminium fistulae et ensurs accurate impletionem. Et tubus implens et signantes apparatus habet salutem munera ut overload praesidium et materiam shortage metum ut ad salutem et reliability de operatione processus. Per plc et tactus screen Imperium Panel, plene automatic tubus filling et signantes processus est intellexit et coding perficitur. Et plasitc fistulam filler reducit difficultatem et laborem intensionem manci operationem.

Product Detail

| Model non | NF-60(AB) | NF-LXXX (AB) |

| Tubus Tail tondetratio | Interiorem calefactio etMechanica mechanism | |

| Fistulam Material | Plastic, aluminium fistulae.compositeABLLaminate tubulis | |

| Statio Gyratorius Indexing | 9 | 12 |

| Tube dia(M) | φ13, φ60 | φ13, φ60 |

| Tubusextendo(M) | 50-220PROMOBILIS | |

| Suatable impleting uber | Cream gel Unguentum toothpaste crustulum cibum condimentumet pharmaceutical, cotidie eget, denique chemical | |

| Filling facultatem(M) | 5-CCLml Novifacta | |

| Tube facultas | A: 6-60ml, B: 10-120ml, C: 25-250ML, D: 50-500ML (Lorem Mythy) | |

| SPECTATIO | ≤ ± I% | |

| TUbes per minute | 45-55tubulis per minute | 40-75tubulis per minute |

| Hopperfacultas: | 4litre | 55Litre |

| Air Specificatio | 0,1 0,1 m3 0.55-0.65MPA / min | |

| Motricium Power | 2KW (380v / 220vIII-phase50-60hz) | 3KW (380v / 220vIII-phaseL-60Hz) |

| Power | 3KW | |

| Dimens(Lxwxhmm) | CXC0 × MXX × MCMLXXX | II7XX × MXX × MCMLXXX |

| Net Pondus (kg) | DCCC | MCCC |

II.Plastic fille filling machinaadopts the tube lifting machine is mechatronic, the whole machine has a reasonable design compacted structure, controlled by PLC, and the height of the tube in the tube groove of the tail sealing machine is monitored by the speed regulating device and the photoeye switch, so as to achieve the synchronization of lifting and tail sealing machine, with a high degree of automation.

3.To ut fistulam non contaminari in elevatio processus, in materia ex parte machina ut contactus in tubo est CCCIV immaculatam ferro, et contactus superficies est plene expolitum cum altum qualitas SS CCCXVI, machinaPotest obviam et exaltatione ex variis tubi et est unus ex provectus metallum, composita (aluminium-plastic) et tubus elevatio apparatu.

IV. Quando mutantur elevatio tubarum diversorum diametri, mechanism disparet commodum et reliable.Et extollens et elevatio sunt stabilis et continua. Cum opus ad celeritatem C tubi per minute, quod elevatio est firmum et continua, quod machinery est firmum et mixless, et non est tubus jamming.

Implens et signantes apparatus pluma

1.12 inch tactus screen Location HMI Siemens PLCPellentesque Tube signare occasus fabrica

II, calidum aeris exhauriunt duct Design ensures tutum opus environmentTube non habet tubum, non implens munus ad consequi salutem

3.Programable imperium automatic fille filling meteringInteriorem calidum aere signing (Leister) (Set usque DC Celsius)

4.filling COLLUM cum aere Canite auto-mundus fistulam munus

5.Quick Mutare Tube Sizes Holder, Securus PurgatoPlastic Tube Filling Machina Usus SS316 Aliquam Steel ad Material Contact partes

VI. Solum usque ad saturitatem cum stillant-probationem implens CERVIX (High Quality SS CCCXVI)Aegra aut vexillum in tubo auto sensor tubus situ stepper motor temperatio orientation

Loading Paperback automatice onerat et signacula plastic fistulae, improvidus productio efficientiam et salvare humanum sumptus

Pelagus configuratione

| NF-LX | NF-LXXX | |

| CONFIGURIUM | Technical parametri | |

| Infrastructure | ||

| Machinaarea | 5m2 | 7m2 |

| Apparatus opusspatio | X m m2 | 12m2 |

| ChillerareaRegio | (de)1m2 | |

| Chiller opusarea regio | (de)2m2 | |

| Machinamagnitudo(L × w × h) | MMDCXX × MXX × MCMLXXX | 27XX × MXX × MCMLXXX |

| Pondus | 850kg | 1100KG |

| Hostis Chassis | ||

| FrameMateria | immaculatam ferroSSCCCIV | |

| SalusostiumPraesideo | PRAEFRACTOR | |

| SAMETYMateria | Speculum organicum | |

| Suggestus | summus qualis immaculatam ferro | |

| HlutumFigura | SPORALIS | |

| Power, Main motor etc. | ||

| Potentiaspecificatio | 380V240V3p L-60Hz/ | |

| Main motricium | 3KW | 3KW |

| Calidum aerem generator consummatio | 3KW(LET (Helvetia)) | |

| Aqua Chiller consummatio | 1.9kw | |

| JacketHopperpotentiam consummatio | 2.0kw | 2.0kw |

| JacketHopper motorpotentia | 0,18 KW

| 0.2kw |

| TUbes per minute (Output capacitatem) | ||

| tubulis per minute | 35--55 | 40--75 |

| Filling range | Plastic / Aluminium Tube3-250ml | |

| Idoneam fistulamsLongitudo | Plastic / AluminiumABLfist50-210mm | |

| Idoneam fistulamsDiameter | Plastic / laminatedABLtubulis 13-50mm | |

| Urgeat fabrica | ||

| Primens ducat principalis pars | SINARUM | |

| Pneumatic Imperium Ratio | ||

| Humilis voltage praesidium | SINARUM | |

| Pneumatica pars | Airtac | |

| Operantes pressura | 0.5-0.7MPA | |

| Caeli consummatio | 30M³ / min | 50M³ / min |

| Electrical Imperium Ratio | ||

| Imperium modus | Plc+Tactus screen (imperium cum plc fundatur) | |

| Plc | Siemens | |

| Frequency inverter | Taida | |

| Tactus screen | Siemens | |

| En Coder | Omron | |

| Filling Detect Image Electric Cell | no | Autonica |

| Totalis potentia switch etc. | Chaleo | |

| Color codice sensorem | BAnner aut male | |

| Calidum Aeris generator | LET (Helvetia) | |

| Idoneam stipare materiale & aliis cogitationibus(Option) | ||

| AptustubusMateria | Aluminium-plastic compositum fistulam et plastic tubo aluminium tubulis | |

| TubusHopper (Loading Paperback) | Transfer tubulis ratePROMOBILIS | |

| Material contactus cum impletionem materiales | High Quality 316L Aliquam Steel | |

| Jacket Layer Hopper Fabrica | Temp. Occasum secundum materiam et impletionem demanda HOpper Material:summus qualis immaculatam ferroSS CCCXVI | |

| SCACTUSMixer | Material Mixing, manet in Hopper summus qualis immaculatam ferroSS CCCXVI | |

| Auto Stamping Fabrica | Una vel duplex lateribusenodeTubuscauda | |

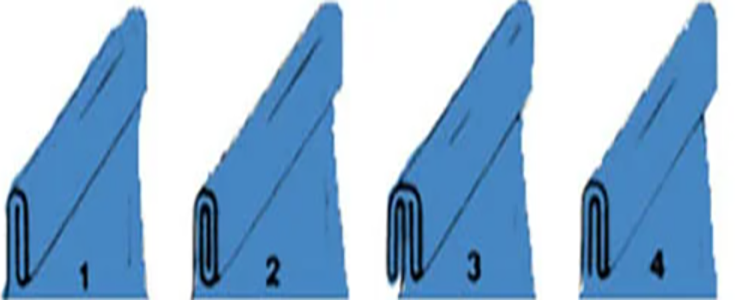

Tubus Tail tondet figura

Nam plastic tubo cauda tondet figura

Nam aluminium fistulae cauda tondet figura

plastic Tube signantes ABL fistulae signa fabrica

Aluminium fistulae signa fabrica

Quid nobis arbitrium

Zhitong est unus de ducens tubo filling machina manufacturers super XV annis focus in tubo filling machinery, QuodTube Filling Machina ManufacturerNam consilium progressionem et faciens venditionis turba maxime focusing inplastic filling et signantes apparatus apparatus rotarius tubo filling machinaEt offer stipare solutio pro nostra customers

I. rationabile consilio, simplex operatio, idoneam ad plures occasum fingit,citoreplacement.

II. Full-Featured, Versatile, idoneam omnes species plastic pipe aluminium-plastic pipe

III. Using PLC ratio ad control vexillum, color Mark deprehensio est magis accurate et iudicium vitae longa.

IV. In materia de contactu parte cum materia est CCCXVI immaculatam ferro, quod obvium est in GMM vexillum.

V. Connection cuiusque pars est in forma velox-loading, quae est convenient ad disassembly et Purgato.

VI. Ad libitum calefacere et calor conservatione permixtionem dolium est convenient ad viscosis et lenis saturitatem.

VII. Uti altus-qualitas pneumaticae components ut magis firmum operationem ex machina

Dolor Zhitong habet plures professio designers, qui potest consilioTubulis implens machinaSecundum ipsa necessitates customers

Placere contact us for free @whatspp LXXXVI15800211936

Products genera

-

E-mail

-

Telephono

-

Top

CL800211936 LXXXVI

CL800211936 LXXXVI