Tubes na-ejupụta igwe maka eriri laminate na eriri aluminom (ruo 320 ppm)

Nkọwa dị mkpirikpi nke igwe na-emeghe ngwa ngwa dị elu:

1. Enwere ike idozi ngwa ngwa ngwa ngwa dị elu, enwere ike idozi ọsọ nke ngwa ngwa, ike nrụpụta ngwa ngwa ngwa igwe nwere ike ịgbanwe.

2,Oke dị elu na-eme ka ihe dị elu na-eme ka ọ dị elu na-eme ka ọ dị elu

2. Ngwaọrụ a na-arụ ọrụ na obere ọsọ maka ọsọ

3

4.

5. Dị ka mkpa ndị ahịa si dị, igwe tube nwere ọtụtụ usoro nke tube nke futs stored na PLC

6

7.

8 .. Oke osisi na-eme ka igwe dị elu na-eme ka igwe kwụ ọtọ na-enweghị atụ na ikuku ikuku na-enweghị atụ na ikuku ikuku, ọkwa nchebe ruru IP65 ma ọ bụ karịa. A ga-eji eriri tube dị n'etiti oche eletriki na igwe eji emechiri emechi emechi, cables banye n'elu igwe ahụ na ọkwa dị elu.

N'ọdịnihu, sistemụ nchịkwa nke igwe na-ejuputa nke elu igwe nwere ike iji Siemens Altaite iji nyefee data na mes ma jikọọ na sistemụ mes.

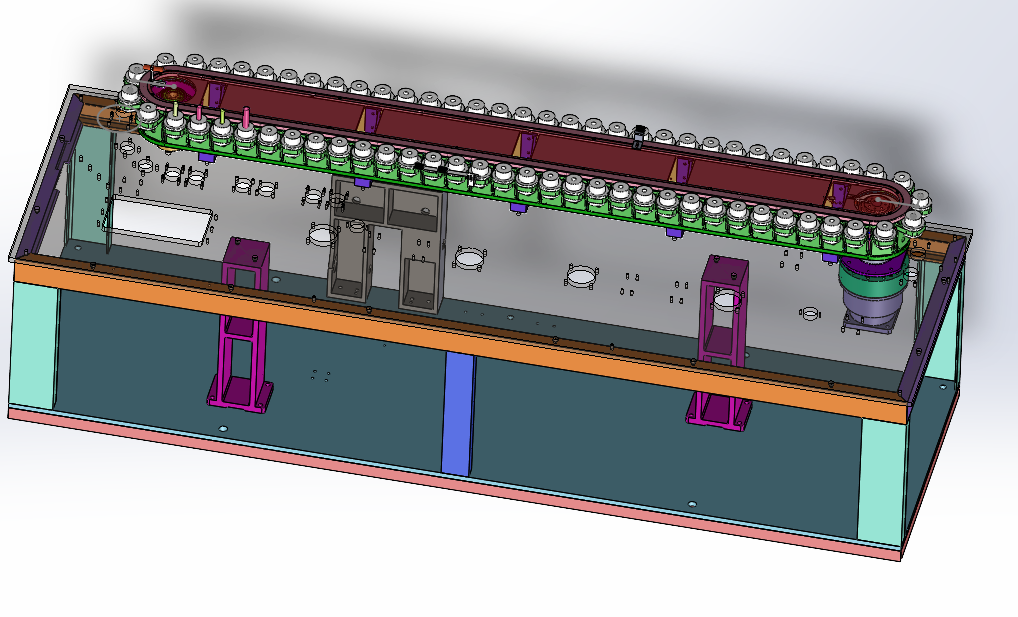

Igwe na-eme ka ọ dị elu na-ejupụta igwe na-acha uhie uhie na eriri aluminom

Igwe na-enyefe igwe Ibelata eriri anọ na-eme ka ọ dị ọdụ na-eme ka ọ dị mma na-emeghe ihe dị iche iche na-eme ka ihe dị iche iche na-emejupụta ihe dị iche iche na-emeghe ihe dị iche iche, nke na-enweghị isi. Na oke ọsọ nkịtị na-emepụta nke fillet bụ tubes 250-340 / nkeji. Ijupụta izi ezi bụ ≤ ± 0.5%. A na-ejikwa eriri akpa a na-akachasị ya site na michie ihe akara, a na-ejikọ ahịhịa na-ekpo ọkụ site na ikuku na-ekpo ọkụ ma ọ bụ teknụzụ ihu igwe dị elu

Igwe eji ebu ibu nke di elu

Igwe na-enyefe igwe dị elu Ibu uzo uzo uzo uzo uzo uzo uzo uzo uzo eji eme ihe eji eme ihe, set nke 4kw Servit na-achupu uzo eji eme ihe. Ngwaahịa dị elu a na-ekpebi oke ọsọ kachasị elu @ 320 tube na-ejuputa kwa nkeji na nkwụsi ike maka mbukota plastik

Oke osisi na-enyefe igwe na-ere ọkụ cutụ iko na-ejikọ Ngwaọrụ na-eme ka ọ dị elu, nke dị ala na ụzọ nduku ụzọ. A na-etinye ihe atọ na-acha uhie uhie na oche oche nke tube cuce, na -akpọgharị na-agagharị n'akụkụ ugwu ma na-anya ụgbọ mmiri. Ibelata igwe igwe enweghị uwe ogologo oge na-agba ọsọ. E nwekwara oghere dị elu na nke ala na-ekunye na atụdo maka ntụgharị maka ntụgharị nke na-agbanwe.

Obere igwe na-eme ka ihe dị elu na-enyefe, ebe a na-ebugharị yinye oche dị elu ma na-edozi oche nke eriri (ụzọ ntụzi ụzọ na-eme ka ọ bụrụ ibe ha site na-ebu eriri eriri. Akpịrị na-eji eriri ezé na-ebugharị eriri na-agba ọsọ siri ike dabere na usoro nnyefe nke wiil na-anya. A na-etinye iko tube na mgbanaka oche ọ bụla. Igwefoto na-ejupụta nwere iko 116 nke nwere ike ijide igwe n'aka na igwe nwere ike ịgba ọsọ dị elu 320 tube / tube tube ma na-ezute nkọwapụta tube na ihe osise.

Ngwa igwe na-eme ka ọ dị elu na-eme ka igwe dị elu na-eme ihe nchebe dị elu site na nloghachi nke ịlaghachi na-agbagharị ọka na-aga n'ihu na ndị nnyefe, nke nwere ndụ ogologo oge. Ọ bụrụ na a na-ejikọ tiji ahụ, a na-egbochi njigide, a na-ejide njigide, na igwe na-akwụsị ozugbo ọbụlagodi na ọsọ ọsọ

Oke osisi na-eme ka igwe dị elu

1. System dị elu na-emejupụta igwe na-emejupụta igwe na hopper nwere ike ihicha ya site na ọdụ cip na emechiri emechi n'otu oge.

2. Tupu ịmalite cip maka igwe na-ejuputa ngwa ngwa, a ga-ewepụ filler filler igwe, nhicha nhicha mmiri site na ọkpọkọ ijikọba site na pipeline jikọrọ na iko cipmy iko.

3. CIP CIP (nke onye ahịa nyere) na-enye ọrụ nhicha na ọnụ ụzọ nke igwe na-enyefe ngwa ngwa. A na-etinye bọl ịgba ọsọ na cylinder ahụ, bọọlụ sprayi spray sprays na-aga n'ihu na-aga n'ihu na ime nke cylinder. A na-eme usoro ndochi plastinic dị ka usoro ọcha, mmiri nhicha ahụ nwere ike iru igwe niile dị elu nke igwe, ọkpọkọ na ngwa ndị na-abanye na ngwaahịa ahụ n'oge tube plastik ahụ. Akụkụ na-agagharị akụkụ nke eriri nmedo nke na-abanye na ngwaahịa a n'oge mmepụta, ga-ebugharị ya n'oge a ga-asachasị akụkụ niile nke akụkụ ndị na-akpụ akpụ.

4.

5

6. Parameters nke igwe na-enyefe igwe dị elu dịka oke ọsọ dị elu. Enwere ike ịtọ ọnọdụ okpomọkụ, nrụgide, ọnụego na oge nke cIP CIP dị ka chọrọ ndị ahịa chọrọ.

7. Ihe juputara nozzles nke eriri ahihia plastik na-esite site na usoro mgbapụta maka nhicha.

8.CPo okporo ụzọ chọrọ maka igwe nhicha dị elu bụ 2T / h ma ọ bụ karịa

Igwe ejiji dị elu na-emejupụta robots na-eri nri (15x2 tubes na ahịrị ugboro abụọ oge ọ bụla, 9-12 / Oge):

Dabere na mmemme mmemme, igwe na-eme ka igwe dị elu nwere robot abụọ na-ewepụta ahịrị nke tube ọ bụla, wee tinye ha na-akwado usoro ngwa ngwa, ma na-eji igwe anaghị agba nchara iji mechie mkpịsị aka ahụ. enwere ike imebi ya maka ihicha ma ọ bụ daa na hydrogen peroxide spray mgbe okirikiri ọpụpụ

Chọpụta ihe ngosi na mkpịsị aka Robot na-etinyebeghị n'ime iko tube, na-eme ka usoro ndọtị mee ihe iji wepu tube site na mkpịsị aka ahụ, wee gaa n'ihu iji tube.

Ngwa nhicha nke LFC4002 LFC4002 nwere uru ndị a:

a. Usoro njikwa: igwe na-eme ka igwe dị elu na-eme ka igwe na-eme ihe na-emetụ ihu igwe na-achịkwa ihuenyo, ndị na-ahụ maka ihe ndị na-ahụ maka ike, na-ejikwa ụgbọ ala zuru oke; Oke mkpọtụ erughi 7,5 ihie.

b. Usoro Indexing: igwe na-emejupụta Sistem dị ka ndebanye aha na-eme ka ọ dị nkọ, na-etolite na ngwa ọrụ na-eme ka ọ dị elu

c. A na-eji ụgbọ mmiri na-eme mkpọtụ na-akpaghị aka na-emegharị ụgbọ mmiri nke na-eme mkpọtụ

d. Ikewapu nke mpaghara: Iberibe plastik na akara igwe nwere ihe na-ebugharị onwe ya, robot clap tube, na-emeju na mpaghara ndị ọzọ dị ka ihe GMP dị.

e. Igwe igbe tube: igwe na-eme ka akpaka na-egbochi ụgbọ njem okpukpu abụọ. A na-ebuga igbe tube ahụ n'elu akwa dị elu, ọkwá dị na ikpo okwu siri ike, yana igbe efu alọghachi na ala oyi akwa.

f. Fuji tube: robot ma ọ bụ igwe na-etinye eriri banye tube, ma nwee ike ịchekwa akpa 3000-4000 afọ.

h. Servononmarmanmarmanmaning: Ọrịa agba na-ejide mgbaama, nnukwu serque Servo Restation, ọsọ na nkwụsi ike.

m. Servo ndochi: Ngwaọrụ na-enye akpaaka na-enye mkpofu ngwá ọrụ zuru ezu na ndozi ceramiiki zuru oke, nke na-agaghị ekwe.

J. Aluminium tube na flotter: clamping na ngwa agha nke ngwaọrụ ọdụ aka bụ nke mbụ scissor-ụdị na-eme ka ikuku banye na tube. gbanwere na mpempe akwụkwọ kwụ ọtọ na usoro a na-eme ngwa ngwa, nke bụ ájá na-enweghị ájá ma zere ịkwọ ụgbọ ala n'ime tube.

k. Aluminom tube ọdụ: Mgbe a na-emechi eriri ọdụ, mpịakọta na clamping sochiri emechi - na mbụ ụdị arc na-enweghị ịdọpụ tube ahụ n'elu. Nke a kwesịrị ekwesị maka ọdụ ọdụ atọ.

n. Nchọpụta onwe gị: Servo na-adọpụ eriri ụzọ anọ ma nwee ọrụ jụrụ.

o. Nchịkọta mmekọrịta: Servitto Intermittent Mmegharị, ọgasị iche na-ekewa, mmekọrịta dị mma.

p. Nrụ ọrụ Holper, na-agbachi ụdị mmeghe ahụ ngwa ngwa nke Popetsa iji jikọọ na mgbapụta ndochi.

q. Cip Cip: enwere ike ihichaa ya n'ịntanetị ma ọ bụ na-anọghị n'ịntanetị.

Nka na ụzụ

- Na-ejuputa igwe eji eme ihe

| No | paramita | ikwu okwu | |

| Nkọwapụta tube (mm) | Dayameta 13 ~ 30, ogologo 60 ~ 250 |

| |

| A na-agba agba agba (mm) | 1.0 |

| |

| Ijupụta ikike (ml) | 1.5 ~ 200 (izute nkọwapụta 5G), nkọwapụta na nha dị iche iche na teknụzụ dị iche iche) |

| |

| Na-ejuputa ziri ezi (%) | ≤ ± 0.5 |

| |

| Ọdụdụ | Mpempe akwụkwọ abụọ, nke ogige, nke ogige dị iche iche dị. |

| |

| Ike mmepụta | 250-300 tube kwa nkeji |

| |

| Kwesịrị ekwesị tube | Aluminom pipe plastik plastik plastik |

| |

| Ike ike (kw) | tube nke filde | 35 |

|

| Robot | 10 |

| |

| Ike | 380v 50hz |

| |

| mmegide ikuku | 0.6MPA |

| |

| Ikuku ikuku (m3/ H) | 20 ~ 30 |

| |

| Mpempe Mgbakwunye | (Ebubata site na Italy) Rubar Sybronous Belt (Servo Drive) |

| |

| Usoro nnyefe | Ngwurugwu Servo zuru ezu |

| |

| nha (mm) | Ogologo 3700 obosara 2000 dị elu 2500 |

| |

| Ngụkọta ọnụ (n'arọ) | 4500 | ||

Smart Zhitong nwere ọtụtụ ndị na-eme atụmatụ ọkachamara, ndị nwere ike imepụtaIgwe na-ejupụta igweDabere na mkpa ndị ahịa

Biko kpọtụrụ anyị maka enyemaka n'efu @GatsPP +8615800211936

Ijupụta na akara igwe nhazi ọrụ

1. Nchọpụta nyocha: (URS) nke mbụ, ndị na-eweta ọrụ gọọmentị ga-enwe mkparịta ụka dị omimi, njirimara ngwaahịa ndị ahịa, njirimara Ngwaahịa na ozi ndị ọzọ dị mkpa. Site na nyocha chọrọ, gbaa mbọ hụ na igwe ahaziri aha nwere ike iji nweta mkpa ndị ahịa.

2. Atụmatụ imewe: Dabere na nsonaazụ nyocha ahụ, onye na-eweta ọrụ nhazi ga-azụlite atụmatụ zuru ezu. Atụmatụ ahụ ga-agụnye usoro eji arụ ọrụ, akara usoro nchịkwa, usoro nhazi usoro, wdg.

3. Ndị ahịa na-akwado atụmatụ a, ndị na-eme ka ọ na-egosi atụmatụ ahụ, ndị ahịa ga-amalite ịmalite ọrụ mmepụta. Ha ga - eji akụrụngwa dị elu na akụkụ dị iche iche dị na atụmatụ atụmatụ iji mepụta ndoputa na iji igwe na - ezute mkpa ndị ahịa.

4. Echichi na debugging: Mgbe emechara emechara, onye na-eweta ọrụ nhazi ga-eziga ndị ọrụ ọkachamara na saịtị ndị ahịa maka nwụnye na debugging. N'ime nrụnye na nhazi usoro, teknụzụ ga-eduzi ya na igwe iji hụ na ọ nwere ike rụọ ọrụ na-abaghị uru ma zute mkpa ọ dị mkpa. Nye abụba na ọrụ

5. Ọrụ ọzụzụ: Iji hụ na ndị ahịa nwere ike iji igwe na-eme ndochi na akara aka nke ọma, ndị na-eweta ọrụ anyị haziri ga-enye ọrụ ọzụzụ (dị ka ịmegharị ọrụ n'ụlọ ọrụ). Ọzụzụ mmụta ahụ gụnyere usoro arụmọrụ igwe, usoro mmezi, usoro nchọpụta nsogbu, wdg. Site na ọzụzụ, ndị ahịa nwere ike ime ka hà dị mma iji igwe na-eme ka arụmọrụ arụpụta).

6. Mgbe onye na-ere ahịa anyị gasịrị: Onye na-eweta ọrụ anyị ahaziri iche ga-enye ọrụ ahịa. Ọ bụrụ na ndị ahịa na-enweta nsogbu ọ bụla ma ọ bụ mkpa nkwado ụzụ n'oge ọ bụla n'oge, ha nwere ike ịkpọtụrụ ndị na-eweta ọrụ na oge ọ bụla iji nweta enyemaka na nkwado.

Usoro mbupu: site na ibu na ikuku

Oge nnyefe: ụbọchị 30 na-arụ ọrụ

1.Tube ijupụta igwe @ 360pcs / nkeji:2.3.4.Tube mkpofu igwe @ 180cs / nkeji:56. Mari tube igwe @ 120cs / nkeji78. Tube ndochi igwe @ 60cs / nkeji

Q 1. Kedu ihe eji tube gi (plastiko, aluminom, bu tube. Ọkpụkpụ apịtị)

Azịza

Q2, kedu ihe bu tube gi juputara na ezi

Azịza: Tube na-emejupụta ikike ga-eme ka usoro sistemụ dosing

Q3, kedu ihe ọrụ mmepụta gị

Azịza: Nkeji ole ịchọrọ kwa elekere. Ọ ga - eduga mmadụ ole juputara na nozzles, anyị na - enye otu ụzọ abụọ atọ na - eju eju n'ime ndị ahịa na mmepụta nwere ike iru ps 360 / nkeji

Q4, Gini bu ihe eji emeju udiri ndu?

Azịza: Njupụta na-agbanwe agbanwe ga-ebute nhọrọ ndochi, anyị na-enye ndị dị ka Willing Services, sistemụ diski dị elu

Q5, Kedu ihe bụ okpomoku jupụta

Zaa

Q6: Kedu ihe bụ akara ọdụ

Azịza: Anyị na-enye usoro ọdụ pụrụ iche, 3D dị iche iche maka ọdụ ọdụ

Q7: Igwe eji eme ihe di ocha

Azịza: Usoro nhicha nke a na-eme ka ọ bụrụ tankị acid, sydọn mmiri, sistemụ anwụrụ, na ala na-adọrọ adọrọ na usoro nchịkwa Alkali na njikwa ihuenyo PLC metụrụ usoro.

Sip dị ọcha ga-emepụta ego, isi na-emetụta ihe niile, ihe ọ bụla na ihe ọ beụ ọgwụ na-egbu egbu maka ịbe

Ngwaahịa atụmatụ

-

E-mail

-

Ekwentị

-

Elu ugwu

0086 15800211936

0086 15800211936