Tubes filling tshuab rau cov yas laminate thiab txhuas raj (txog li 320 ppm)

Luv luv luv ntawm kev siab ceev raj filling tshuab:

1. Cov hluav taws xob servo ntawm kev kub ceev raj filling tshuab tuaj yeem kho qhov ceev ntawm lub tshuab raj ua kom ceev tuaj yeem hloov kho.

2,Kev kub ceev raj filling tshuab Tsim ceev 320 raj filling ib feeb.thiab ib txwm ceev yog li 280 raj filling ib feeb

2. Lub jog ntaus ntawv ua haujlwm ntawm qhov nrawm nrawm rau kev khiav yooj yim

3. Vaj huam sib luag tseem ceeb (HMI) los kho txhua txoj haujlwm ntau lawm txoj kab uas hla

4. Lub lag luam vaj huam sib luag qhia cov khoom thiab cov kab ntau lawm rau kev saib xyuas

5. Raws li cov neeg siv khoom xav tau, cov tshuab raj muaj ntau cov qauv ntawm cov tub hlau uas muab tub rog khaws cia

6 .. Kev Kub Siab Ceev Tube Filling Tshuab Tswj Vaj Huam Sib Luag tuaj yeem tsim parameter functions

7 .. Lub tshuab xaav filling tshuab muaj vaj huam sib luag haujlwm tiv thaiv los ntawm 3 txoj haujlwm ntau qib ua haujlwm rau kev tswj hwm txoj cai

8 .. Kev siab ceev lub raj filling tshuab tau txais cov stainless hlau Independment hluav taws xob txee rau cov cua txias, kev tiv thaiv qib mus txog IP65 lossis siab dua. Cov tais diav ntawm cov raj muab ua chaw rau ntawm cov tshuab hluav taws xob thiab cov tshuab kaw kaw, cables sau rau sab saum toj ntawm lub tshuab ntawm theem siab.

Nyob rau yav tom ntej, tswj kev ua kom siab ceev rajfab raj filling tshuab tuaj yeem siv siemens cov ntaub ntawv los hloov cov ntaub ntawv rau cov lus qhia mes thiab txuas nrog MES system.

Kev Siab Ceev Lub Tshuab Filling Tshuab Rau Yas Laminate Thiab Txhuas Tube

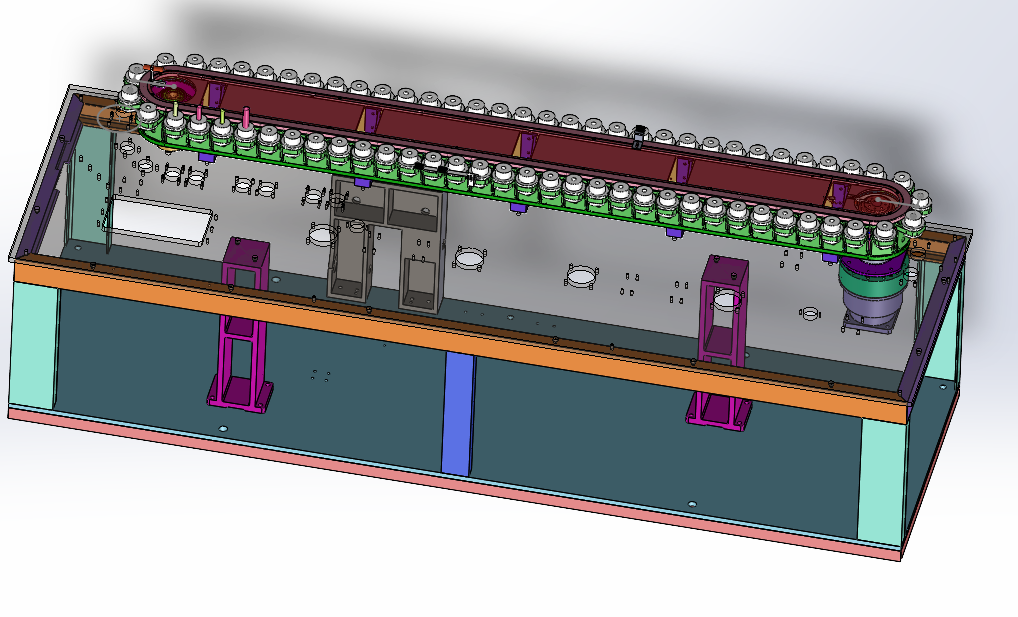

LFC4002 Kev Siab Ceev Lub Tshuab Filling Tshuab yog plaub-chaw nres tsheb puv thiab sealing raj filler. 250-340 hlab / feeb. Kev sau yog ≤ ≤ ≤ ≤. 0.5%. Cov raj roj txhuas raj yog ntim los ntawm folding seeded los ntawm folding seeding, aluminium composite raj yog kaw los ntawm huab cua kub lossis cua sov zaus

Kev siab ceev cov raj filling tshuab tshuab loj tuaj:

Kev siab ceev raj filling tshuab Adopts ib qho kev sib tw ntawm kev sib tw ntawm kev sib tw. Lub tshuab hluav taws xob kub siab tshaj plaws txiav txim siab qhov siab tshaj plaws ntawm kev kub siab @ 320 raj filling ib feeb thiab kev ruaj khov rau yas raj filling thiab sealing ntim

Kev siab ceev cov raj filling tshuab raj khob cov cuab yeej connitect cov cuab yeej muaj peb grooved sab sauv, qis dua thiab alloy steel qhia ntsia hlau. Peb cov kabmob uas tau muab khi rau ntawm lub khob raj ntawm lub khob, thiab cov kabmob dov tawm ntawm cov leeg thiab tsav lub raj. Filling tshuab saw tsis muaj hnav rau ntev khiav. Kuj tseem muaj ob lub duav thiab sab hauv cov menyuam cov kabmob mounted rau pins rau kev sib hloov rau lub raj loj hloov.

Kev siab ceev lub raj filling tshuab, lub raj conveyor saw pob khawm hinges thiab kho cov raj tsoos (peb-cov lus qhia kev tsheb nqaj hlau) rau txhua lwm yam los ntawm kev txhuam hniav ntawm hniav. Tus txhuam hniav ntawm txoj siv ntawm raj Lub khob raj yog mounted rau txhua lub nplhaib raj. Filling tshuab muaj 116 lub khob raj kom paub tseeb tias cov tshuab yuav khiav ceev cov khoom siv lub teeb thiab ua tau raws li cov raj spreifications thiab tsim qauv.

Kev kub ceev raj filling tshuab conveyor saw muaj kev tiv thaiv tshaj plaws yog ua los ntawm lub hauv paus rov qab los ntawm kev sib kis lub log, uas muaj lub neej kev pabcuam ntev. Yog hais tias lub saw raj daig daig, lub clutch yog disconnected, lub qhov sib thooj hloov yog txhais tau tias, thiab cov tshuab nres tam sim ntawd txawm tias nyob rau hauv qhov kev kub ceev khiav xwm txheej

Kev siab ceev raj filling tshuab Eonline Tu Txheej Txheem

1. Kev siab ceev lub raj filling tshuab filling system thiab Hopper tuaj yeem ntxuav tau ncaj qha los ntawm lub voj voos kaw lus nyob rau tib lub sijhawm.

2. Ua ntej pib CIP rau siab so lub raj filling tshuab, raj filler lub raj raj ntsaws rau ntawm cov raj dej yas sib txuas nrog lub khob dummy.

3. CIP kev ua haujlwm (muab los ntawm cov qhua tuaj noj mov) muab kev pab tus neeg sawv cev rau kev nkag ntawm lub plhaw ntawm kev kub ceev raj filling tshuab. Lub pob tshuaj tsuag tau nruab rau hauv lub tog raj kheej, thiab cov pob tshuaj tsuag sprays tus neeg sawv cev tu ntawm sab hauv lub tog raj kheej. Lub raj raj sealing tshuab sau system yog tsim raws li kev ua kom huv si ntawm lub raj mis uas tau nkag mus rau hauv lub tshuab yas raj sealing tshuab txheej txheem. Tsiv qhov chaw ntawm cov raj muab muab ua thawv rau ntawm cov khoom lag luam, xws li siv piston, agitators, thiab lwm yam.

4. Qhov sib txuas cov yeeb nkab rau kev ntxuav cov kua dej kom rov qab rau cov qhua tuaj noj mov ntawm cov neeg siv khoom siv lub tshuab nqus dej tsis suav nrog cov khoom siv)

5. Yas Thuam Sealing Siv thiab cov tshuaj tua kab mob sib txuas ua raws li cov neeg siv khoom, thiab kev tu thiab tshuaj tua kab mob tau teeb tsa hauv chaw nres tsheb ciph

6. Qhov tsis muaj ntawm lub siab ceev raj filling tshuab xws li kev kub ceev parameter. Qhov kub thiab txias, txaus, ntws tus nqi thiab lub sijhawm ntawm lub voj voog CIP tuaj yeem tsim los ntawm CIP chaw nres tsheb raws li cov neeg siv khoom.

7. Lub tshuab txhaws ntawm lub tshuab yas ntim puv tshuab tseem tuaj yeem tau ceev ceev los ntawm cov twj tso dej kom huv.

8.Cov tsheb khiav yuav tsum rau lub siab ntim kom ceev lub tshuab yog 2t / h lossis siab dua

Kev kub ceev lub raj filling tshuab txais cov neeg hlau kom pub cov hlab (15x2 hlab nyob rau hauv ob npaug ntawm ob zaug, 9-12 zaug / feeb):

Raws li cov phiaj xwm programmed, kev kub siab ceev lub raj raj tshuab muaj cov raj ntawm lub khob raj, cov neeg hlau muaj cov hlau raj ua kom nruj cov ntiv tes. tuaj yeem rhuav tshem kev tu thiab tshuaj tua kab mob lossis tsau tshuaj nrog tshuaj tua kab mob hydrogen portoxide thaum lub siab ceev raj muab tso rau

Cov grating kuaj seb muaj ib lub khob dej hauv tus ntiv tes uas tsis tau tso rau hauv lub khob raj kom tshem tawm cov raj tawm ntawm cov ntiv tes, thiab tom qab ntawd nyuas ua kom lub raj.

LFC4002 Kev Siab Ceev Tube Filling Tshuab muaj cov txiaj ntsig hauv qab no:

a. Tswj system: Kev siab ceev raj khawv secints Siemens Kov Screen thiab Japanese keytic maub los tswj hwm; Lub suab nrov yog tsawg dua 75 decibels.

b. Indexing Mechanism: Filling tshuab Servo System ua qhov kev hloov pauv ntawm lub tshuab yas ua kom ntev dua ntawm lub cav yas kom ua tau zoo li qub

c. Khob saw kab qhia kev sib tw: Lub tshuab ua lag luam ua haujlwm siab rau cov tsheb ciav hlau siab, kev sib tw ntawm lub tshuab hlau siab thaum tshuab

d. Kev sib cais ntawm cov cheeb tsam: Yas Raj Foo filling thiab sealing tshuab muaj kev thauj khoom, Faib tsis siv neeg thauj khoom, tshuab muag khoom, servo raj muab tso tawm thiab lwm thaj chaw sib cais raws GMP cov kev xav tau.

e. Tube kem tso tawm: Tsis siv neeg lub raj raj Lub thawv raj thauj khoom no tau thauj ntawm cov txheej sab saud, muab tso rau ntawm lub platform inclined, thiab lub thawv khoob tau rov qab los ntawm txheej qis dua.

f. Raj chaw thau khoom txoj kev: Neeg hlau lossis raj thauj khoom siv lub tshuab nkag rau hauv cov leeg, thiab tuaj yeem khaws 3000-4000 leeg txhua zaus.

h. Servo Benchmarking: Cov Xim Muaj Mob Lub cim ntes cov teeb liab, loj torque servo kev sib hloov ua haujlwm, kev kub ceev thiab ruaj khov.

Kuv. Servo Sau: Tsis siv neeg lub raj raj tshuab adops puv-kab servo tsav thiab tag nrho cov twj tso kua mis txhaws, uas yuav tsis hnav.

j. Aluminium raj clamping thiab flattening: clamping thiab flattening txheej txheem yog Ameslikas clissor-hom clamping flattening, uas tuaj yeem yooj yim nias cua rau hauv lub raj. Hloov mus rau CLACT CLAMPING thiab FLATTHANIORCECHISHIOR, uas yog hmoov av dawb thiab zam kev tsav tsheb mus rau hauv lub raj.

k. Aluminium Tube Tail sealing: Thaum se ntxias cov raj tw tw, cov kab ntawv admin ntawm cov khoom sib txuas (keeb kwm ib hom kev txav mus los) Qhov no yog qhov tshwj xeeb tshaj yog haum rau peb pawg tails.

n. Kev rho tawm cov cuab yeej: servo eject rau plaub-txoj kev raj thiab muaj kev tsis lees paub ua haujlwm.

o. Synchronous conveying: servo sib quas ntus txav, cais lub ntsej muag conveying, zoo synchronization.

p. Kev Tiv Thaiv Siab Siab Hopper: Adopts cov hom qhib nrawm nrawm ntawm cov faib yeeb nkab txuas rau txuas rau lub tshuab puv.

Q. Internal Cip: Nws tuaj yeem ntxuav online lossis offline.

Kev Lag Luam Kev Lag Luam

- HLUB FILLING TSHUAB Lub Equipment Kev Qauv

| No | chaw ua uas tsis tau haus | hais lus | |

| Raj specification (mm) | Inch 13 ~ 30, ntev 60 ~ 250 |

| |

| Xim Cim Nyem Tso Tawm (MM) | ± 1.0 |

| |

| Sau muaj peev xwm (ml) | 1.5 ~ 200 (Ntsib 5G-50G specifications, cov lus qhia tshwj xeeb thiab ntau yam tshwj xeeb raws li ntau yam thiab thev naus laus zis) |

| |

| Sau qhov raug (%) | ≤ ≤ |

| |

| Sealing Tails | Ob-quav, peb-quav, thiab cov quav tu siab yog muaj. |

| |

| Tso Rau Muaj Peev Xwm | 250-300 raj ib feeb |

| |

| Lub raj haum haum | Txhuas yeeb nkab yas yeeb txhuas yas cov yeeb nkab |

| |

| Kev Siv Hluav Taws Xob (KW) | Tube Ntawm Muab Zov | 35 |

|

| Lub tshuab | 10 |

| |

| Hwjchim | 380V 50HZ |

| |

| Cua Siab | 0.6mpa |

| |

| Kev noj cua (m3/ h) | 20 ~ 30 |

| |

| Kis tau cov qauv | (Imported los ntawm ltalis) rebar synchronous rail hom (servo tsav) |

| |

| Hloov Tsheb Tshuab | Puv Servo Tsav |

| |

| Qhov loj me (hli) | Ntev 3700 Dav 2000 Qhov Siab 2500 |

| |

| Qhov hnyav tag nrho (kg) | 4500 | ||

Ntse Zhitong muaj ntau tus kws tshaj lij tsim qauv, uas tuaj yeem tsim qauvTubes Filling TshuabRaws li cov kev xav tau tiag tiag ntawm cov neeg siv khoom

Thov hu rau peb dawb rau kev pab pub dawb @Whatspp +8615800211936

Sau thiab sealing tshuab customization cov txheej txheem

1. Xav soj ntsuam: (urs) ua ntej, cov kev pabcuam kev pabcuam customization yuav muaj kev xav tau kev pab cuam customer, cov yam ntxwv cov khoom lag luam thiab cov ntaub ntawv tseem ceeb thiab lwm cov ntaub ntawv pov thawj. Los ntawm kev xav tshawb xyuas, xyuas kom meej tias cov tshuab customized tuaj yeem ua tau raws li cov neeg siv khoom tiag tiag.

2. Cov phiaj xwm tsim qauv: Raws li cov txiaj ntsig ntawm kev xav tau kev tshawb xyuas, cov chaw pabcuam customization yuav tsim cov ncauj lus kom ntxaws. Txoj kev tsim qauv yuav muaj xws li cov qauv tsim ntawm lub tshuab, tswj cov qauv kev tsim qauv, txheej txheem ntws los ntawm kev tsim, thiab lwm yam.

3. Mekas Ntau Lawm: Tom qab tsim qauv tau lees paub los ntawm cov qhua tuaj noj mov, tus muab kev pabcuam customization yuav pib ua haujlwm ntau lawm. Lawv yuav siv cov ntaub ntawv raw zoo thiab qhov chaw nyob rau hauv raws li cov cai ntawm kev tsim khoom tsim thiab sealing tshuab uas tau raws li cov neeg siv khoom siv.

4. Txhim kho thiab debugging: tom qab ntau lawm ua tiav, cov kws pabcuam pabcuam customization yuav xa cov kws tshaj lij kev tshaj lij rau cov qhua tuaj noj mov rau kev teeb tsa thiab debugging. Thaum lub sij hawm cov txheej txheem teeb tsa thiab commissioning yuav ua kev tshawb fawb thiab kev kuaj siab rau lub tshuab xav tau nws thiab ua tau raws li cov neeg siv khoom muaj kev xav tau. Muab cov kev pab muaj rog thiab SAT

5. Kev pabcuam kev cob qhia: txhawm rau kom ntseeg tau tias cov neeg siv khoom siv tau cov chaw muab kev pabcuam, peb yog debugging (xws li debugging (xws li debugging). Cov ntsiab lus kev cob qhia suav nrog cov txheej txheem tshuab kev khiav haujlwm, kev txij nkawm txoj kev, cov hau kev daws teeb meem, thiab lwm yam. Los ntawm kev cob qhia, cov neeg siv khoom tuaj yeem ua cov txuj ci zoo dua ntawm kev siv lub tshuab thiab txhim kho ntau dua kev ua tau).

6. Tom qab kev pab cuam tom qab muag: peb cov kws kho mob cusidized tseem yuav muab kev pabcuam tom qab muag. Yog tias cov neeg siv khoom tau ntsib cov teeb meem lossis xav tau kev txhawb nqa kev siv nyiaj thaum siv, lawv tuaj yeem tiv tauj cov neeg muab kev pabcuam rau lub sijhawm twg los tau kev pab kom raws sijhawm thiab txhawb nqa.

Kev xa khoom: Los ntawm cov khoom thauj thiab cua

Lub sij hawm xa tuaj: 30 hnub ua haujlwm

1.TO sau tshuab li @ 360pcs / feeb:2. Lub tshuab filling tshuab @ 280Cs / feeb:3. Raj filling tshuab @ 200cs / feeb4.Tube Filling tshuab @ 180cs / feeb:5. Raj filling tshuab @ 150cs / feeb:6. Raj filling tshuab @ 120cs / feeb7. Raj filling tshuab @ 80cs / feeb8. Raj filling tshuab @ 60cs / feeb

Q 1.What yog koj cov raj khoom (yas, sib xyaw ua ke, composite raj. Abl raj)

Teb, cov khoom siv raj yuav ua rau kev sib khi ntawm cov raj yas, cua sov, cua sov, cua sov thiab ntaus cua kub thiab tus tw ciav hlau

Q2, koj lub raj muaj peev xwm thiab qhov raug

Teb: Tube puv puv yuav tsum muaj tshuab dosing system configuration

Q3, koj cov kev cia siab muaj peev xwm muaj peev xwm

Teb: Koj xav tau pes tsawg daim koj xav tau ib teev. Nws yuav ua kom muaj pes tsawg filling nozzles, peb muab ib ob peb plaub thib ib txhaws cov qhua tuaj noj mov rau peb cov neeg siv khoom thiab cov zis tuaj yeem ncav cuag 360 pcs / feeb

Q4, cov khoom ntim tshuab hluav taws xob zoo nkauj yog dab tsi?

Cov lus teb: Cov khoom siv filling cov viscamed viscamosity yuav ua rau kev xaiv kom puv, peb muab xws li txhaws servo system, siab pneumatic noj tshuaj

Q5, dab tsi yog qhov txhaws ua kom sov

Teb: Qhov sib txawv sau ntsuas kub yuav xav tau cov khoom siv cia (xws li lub tsho wayper, tov khoom, ntsuas kub thiab lwm yam)

Q6: Dab tsi yog cov sealing tails zoo

Teb: Peb muab tus Tsov tus tw tshwj xeeb, 3D sib txawv rau tus Tsov tus tw sealing

Q7: Puas yog lub tshuab xav tau CIP huv system

Teb: Daim ntaub hlau tu kom huv tau feem ntau muaj cov tso tsheb hlau luam yeeb, cov tso tsheb cua sov, cov tso tsheb cua sov, cov tshuaj lom dej ntau thiab cov pa roj alkali concentrated thiab plc kov screen tswj.

CIP Kev Kho Kom huv yuav tsim kev peev ntxiv, tseem ceeb siv rau yuav luag txhua yam zaub mov, dej haus thiab chaw muab tub luam yeeb

Cov khoom lag luam

-

E-mail

-

Lub xov tooj

-

Lub ncov roob

0086 15800211936

0086 15800211936