Tubes cike na'ura don lalatawar filastik mai filastik da tubalin aluminum (har zuwa 320 ppm)

Bai dace da taƙaitaccen bayani game da babban bututun mai cike da injin ba:

1. Servical Servo na babban bututun bututun mai cike da injin yana iya daidaita saurin daban-daban, ana iya daidaita saurin samar da injin fil na bututun.

2,Babban bututun mai gudu cike da sauri na injin yana cikin tsawan bututun 320 na bututu mai tsayi a minti daya shine kusan bututun bututun 280 yana da sau 28

2. Kwayar Jog tana aiki da ƙarancin sauri don sauƙi

3. Babban kwamitin (HMI) don daidaita duk tsarin diamita na samarwa

4. Babban kwamitin ya nuna kan samari da matsayin layin samarwa don lura

5. A cewar bukatun abokin ciniki, bututun bututu yana da tsarin tsari da yawa don bututun mai ajiya a PLC

6.. Babban bututun mai gudu cike kwamitin kula da injin na iya saita ayyukan sigogi

7

8 .. Babban bututun mai gudu wanda ya cika injin karfe mai zaman lafiya mai zaman lafiya tare da kwandishan, matakin kariya ya kai IP65 ko sama. Na USB trays na bututu mai shimfiɗa tsakanin kabad na lantarki da injina suna amfani da rufin kebul na kebul, igiyoyi sun shiga saman injin a babban matakin.

A nan gaba, tsarin sarrafawa na babban tubalin bututun mai cike da injin na iya amfani da Siemens foukisi don canja wurin bayanai zuwa MES da haɗa tare da tsarin MES.

Babban bututu mai sauri cike injin don lalatattun filastik da kuma bututun aluminum

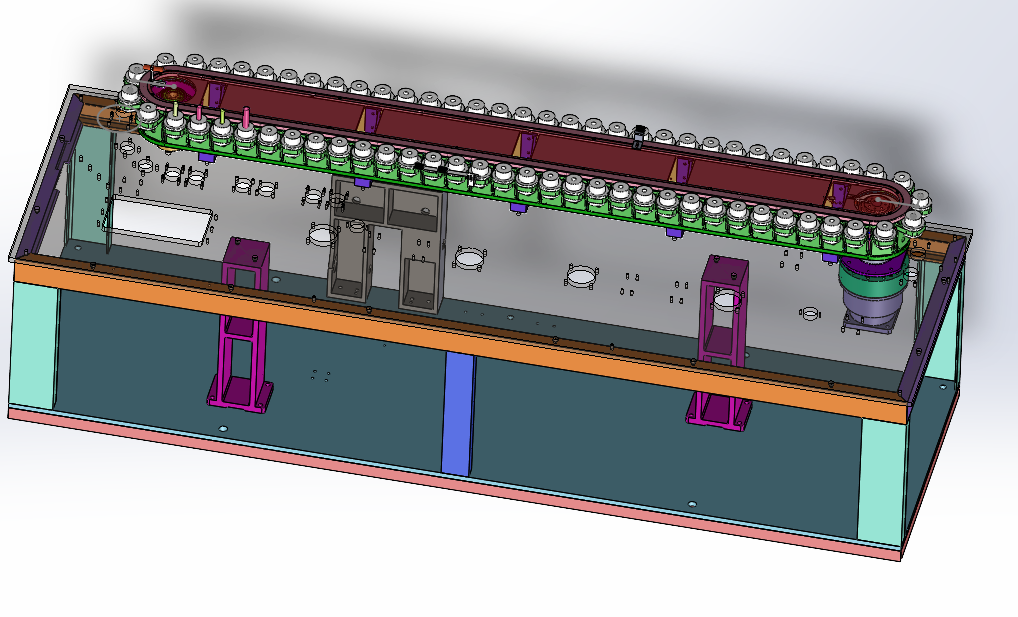

Lfc4002 babban bututun mai gudu cike injin shine tashar hawa huɗu da ta cika filler .epeloblafe cikakken bututun filastik wanda aka tsara a minti daya, da ba bakararre da aka kirkira ba, saurin ƙira ya cika tsari, saurin ƙira shine 320 Tubes / Minute, da ainihin iyakar saurin samar da tube na filler shine 250-340 shambura / minti ɗaya. Cika daidaito shine ≤ ± 0.5%. An rufe sashi na aluminum na aluminum ta hanyar ninka bututun, aluminum-filastik wanda iska mai zafi ya rufe ta iska ko babban fasahar dumama

Babban bututu mai sauri cike mahimman kayan sarrafawa

Babban bututu mai gudu cike injin Dauke da kayan kwalliya na muloy dogo dogo, wanda ya tsananta sau uku-tsinkaye uku-akidar da ya haifar da tube sarkar sarkar. Wannan injin mai sauri yana ƙayyade matsakaicin babban gudu @ 320 butbe cika minti da kwanciyar hankali don bututun bututun filastik cika da hatimin bututu mai cike da filastik

Babban bututu mai sauri cike na'urar sarkar kofin sarkar ya ƙunshi grooved babba, ƙananan da gefe alloy karfe jagorar jagorar. An sanya m mirgine a kan wurin zama na Tube, da kuma munanan abubuwa suna motsawa bisa ga tsummoki kuma fitar da tubes. Cikakken sarkar ba ta da sutura na dogon lokaci. Haka kuma akwai maɓallin keɓaɓɓun kayan haɗi guda biyu da aka ɗora akan fil don juyawa don juyawa ga bututun girman bututu.

Babban bututun mai gudu cike injin, sarkar sarkar sarkar kuma tana gyara kujerun sarkar (wurin saitawa na bututu uku, suraje shiriya) ga jakar jigilar kaya. Bel da bel da bel na bututun mai cike da injin ya mamaye injin da ke cike da yanayin watsa yanayin tuki. Tube kofin yana hawa akan kowane zobe na bututu. Injin cike kofuna waɗanda 1166 sun tabbatar da cewa injiniya na iya tafiyar da babban sauri 320 bututu wanda aka yi da babban wutar pom na ruwa da kuma bukatun Tube.

Babban bututun mai gudu wanda ya cika sarkar aikin isar da injin da aka samu ta hanyar dawowar daidaitaccen aiki ta Torque da aka sanya a kan watsawa, wanda ke da dogon rayuwa mai tsayi. Idan sarkar bututu ya makale, ana cire haɗin kogon, an kunna kusancin kusurwa, kuma injin ya tsaya nan da nan ko da a cikin matsayin babban aiki

Babban bututu mai sauri cike tsari na tsabtatawa

1. Babban bututun mai sauri cike injin da ke cike tsarin da aka cika da tashar CIP ta tashar CIP a cikin rufaffiyar madauki a lokaci guda.

2. Kafin fara cip don high buhen bututun mai da aka sanya tare da takamaiman ciyawar bututun filastik ta hanyar bututun ruwa.

3. Cikin cinikin kwastomomi (wanda abokin ciniki ya bayar) yana ba da wakilin tsabtatawa zuwa ƙofar hancin na hpper na hpper na high gudun tube bututu mai cike injin da ke cike injin cika. An shigar da kwallon da aka fesa a cikin silima, da feshi fesa sprays da tsabtatawa mai tsaftacewa a saman farfajiya na silinda. A filastik bututun mai cike da tsarin injin cike an tsara shi gwargwadon ka'idodin hyggienic, kuma ruwan tsaftacewar ciki da kayan aiki waɗanda ke hulɗa da samfurin yayin tsarin filastik na filastik. Motsa kayan masarufi na injin fillashin da ke cikin amfani da samfurin yayin aiwatar da kayan piston, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu, da sauransu.

4. Bututun mai haɗi don ruwan tsaftacewa don komawa zuwa tsarin cinikin abokin ciniki na babban hawan bututun mai cike injin da ke cike da wadataccen wadata)

5.

6. Sigogi na babban bututun bututu mai cike da injin kamar babban sigogi. Zazzabi, matsi, ragi da ke gudana da lokacin lilin CIP za a iya saita ta tashar CIP ɗin a bisa ga buƙatun abokin ciniki.

7. Cikakken nozzles na filastik bututun mai kuma za'a iya hanzewa daga tsarin famfon don tsabtace shimfida.

8. cunkoso na zirga-zirgar na buƙatar injin haye mai sauri shine 2t / h ko sama

Babban bututu mai sauri cike injin da ya karbi robots don ciyar da bututu (15x2) a cikin layuka biyu kowane lokaci, sau 9 / minti):

A cewar shirin da aka shirya, babban tube bututun yana ɗaukar layuka biyu na cire bututun, kuma yana amfani da bakin karfe don ɗaure yatsunsu. Za a iya watsa don tsabtatawa da kuma kamuwa da cuta ko ya hana shi tare da frayrogen peroxide lokacin da tube mai sauri filler ya tsaya

Aintin gano ko akwai bututun a cikin yatsan robot wanda ba a saka shi cikin kofin bututu ba, sannan ya ci gaba da ɗaukar bututun.

LFC4002 Babban Tube Tube bututu mai cike na'ura yana da waɗannan fa'idodi:

a. Tsarin sarrafawa: Haske mai sauri mai saurin cika injin da keɓaɓɓe Siemens Techens da mai kula da Koyence Motsa Jafananci, Bust Setro bas, cikakken direba ya kori; hayaniya ba kasa da 75 decibels 75.

b. Inji mai tsari: injin cika yana amfani da tsarin Servo azaman injin haɓaka na injin da ke gudana a tsaye @ ku tsayar da saurin soft filastik 260pcs bututu mai cika mintuna

c. Jirgin Sarkar Jagorar Gasar Cin Kofin Sarkar Gudanar da Kaya

d. Rage wuraren: bututun filastik na filastik yana da aikin tubalin da za a saukar da shi, mai ɗaukar hoto tube da kuma wasu wuraren sun rabu da bukatun Gandar Gobo.

e. Box akwatin wuri: bututu na atomatik cika inji dauki sau biyu-Layer sufuri. Ana jigilar akwatin bututun a saman Layer, sanya a kan dandalin karkata, kuma akwatin fox ɗin an dawo kan ƙananan Layer.

f. Hanyar saukarwa na bututu: robot ko injin saukarwa na shiga shambura, kuma yana iya adana shambura 3000-4000 kowane lokaci.

h. Servo Benchming: Alamar kama alama, babban torque serno rotation save, babban gudu da kwanciyar hankali.

i. Servo ciko: bututun bututu na atomatik cika na'ura mai amfani da layin Servo drive da kuma cikakken pateram na cika, wanda ba zai taɓa fashewa ba.

j. Tubalin aluminum na aluminum da tsiro: clamping da tsabtace kayan aikin wutsiya ya samo asali ne a cikin iska-nau'in a cikin bututun. An canza shi zuwa wani kwance a kwance da kuma haskakawa, wanda shine ƙura mai ƙura da kuma guje wa gas mai tuki a cikin bututu.

k. Aluminum Tube Tube wutsiya: Lokacin da aka buga wutsiya na bututu, da murmurewa da ke haifar da daidaitattun motsi na kwance a sama. Wannan musamman ya dace da wutsiyoyi uku.

n. Fitar na'urar: Servo ya fitar da bututun hanya huɗu kuma tana da aikin kin amincewa.

o. Synchronous isar da kai: Motsa Serbo Servitent Movement, raba daban-daban isar da, kyakkyawan aiki tare.

p. Hopeper Hoper: Kidaya yanayin buɗe-hanzari na bututun mai don haɗawa da cika famfo.

Tambaya. CIP na kan layi: ana iya tsabtace ta yanar gizo ko layi.

Sigar fasaha

- Tubes cike mahimmancin kayan aikin kayan aiki

| No | misali | nuna ra'ayi | |

| Bayanin bututu (mm) | Diamita 13 ~ 30, tsawon 60 ~ 250 |

| |

| Markar launi wurin (mm) | ± 1.0 |

| |

| Cika ikon (ML) | 1.5 ~ 200 (Haɗu da bayanai na 5G-50g, takamaiman ƙayyadaddun bayanai da masu girma dabam bisa ga alamomi da fasaha) |

| |

| Cika daidaito (%) | ≤ ± 0.5 |

| |

| Rufe wutsiyoyi | Ninka biyu, ninka biyu ninki biyu, da saddle-saddle-mai siffa-glats suna samuwa. |

| |

| Karfin fitarwa | 250-300 bututu a minti daya |

| |

| Bututu mai dacewa | Pilum bututun filastik bututun kayan aluminum fil fil filast |

| |

| Amfani da iko (kW) | bututu na filler | 35 |

|

| Inji mai aiki da kansa | 10 |

| |

| Ƙarfi | 380V 50Hz |

| |

| matsin iska | 0.6mpsa |

| |

| Amfani da iska (m3/ h) | 20 ~ 30 |

| |

| Hanyar watsa sarkar | (An shigo da shi daga Italiya) Rebar Hitchrony Belt (Drive Servo) |

| |

| Hanyar watsa | Cikakken servo drive |

| |

| Girman (mm) | Tsawon shekaru 3700 sama da tsayi na 2000 2500 |

| |

| Jimlar nauyi (kg) | 4500 | ||

Smart Zhitong yana da masu tsara ƙwararru, waɗanda zasu iya zaneTubes cike na'uraDangane da ainihin bukatun abokan ciniki

Da fatan za a tuntuɓe mu don taimako kyauta @whatspp +8615800211936

Cikawa da rufe tsarin tsarin aikin

1. Buƙatar bincike: (Urs) Mai ba da sabis na Abokin Ciniki Zai Yi Tadarwa na cikin Cikin Cikin Abokin Ciniki, Abubuwan Kayan aiki, Abubuwan da ake buƙata da Sauran mahimman bayanai. Ta hanyar bincike na buƙata, tabbatar cewa injin al'ada zai iya biyan ainihin bukatun abokan ciniki.

2. Tsarin ƙira: Dangane da sakamakon binciken ne na buƙata, mai ba da sabis na sabis zai bunkasa tsarin ƙira. Tsarin ƙira zai haɗa da ƙirar tsarin na injin, sarrafa tsarin tsari, Tsarin Tsarin Tsarin, da sauransu.

3. Abubuwan da aka tsara: Bayan an tabbatar da tsarin ƙirar ta hanyar abokin ciniki, mai ba da sabis na sabis zai fara aikin samarwa. Zasuyi amfani da kayan masarufi masu inganci da sassan daidai da bukatun shirin kirkirar shirin don kera injunan da aka gina don samar da injunan da ke rufe.

4. Shigarwa da Debuging: Bayan samarwa an gama, mai ba da sabis na ci gaba zai aika masu fasaha ga rukunin yanar gizo don yanki na abokin ciniki don yanki. A lokacin shigarwa da kwastomomi, masu fasaha za su gudanar da bincike da gwaje-gwaje akan injin don tabbatar da cewa zai iya aiki akai-akai da saduwa da bukatun samar da abokin ciniki. Bayar da kuɗi da sat

5. Ayyukan horarwa: Domin tabbatar da cewa abokan cinikin na iya amfani da cika da hatimin da muke buƙata, masu ba da sabis na musamman za su kuma samar da sabis na horarwa (kamar kewaya a cikin masana'antar). Abubuwan da ke ciki ya ƙunshi hanyoyin aikin injin, hanyoyin kulawa, hanyoyin matsala, da sauransu. Ta hanyar horarwa, abokan ciniki zasu iya mafi kyawun kwarewar amfani da injin kuma inganta haɓakar samarwa).

6. Sabis na tallace-tallace: Mai samar da sabis na musamman zai kuma samar da cikakken sabis na tallace-tallace. Idan abokan ciniki sun haɗu da kowace matsala ko buƙatar tallafin fasaha yayin amfani, zasu iya tuntuɓar mai ba da sabis na musamman a kowane lokaci don taimakawa da taimako na lokaci da tallafi na lokaci.

Hanyar jigilar kaya: ta hanyar kaya da iska

Lokacin isarwa: Kwanakin Aiki 30

1.Tube cika inji @ 360pcs / minti:2. Bututun bututu @ 280cs / minti:3. Bututun mai @4.Tube cika inji @ 180cs / minti:5. Bututun bututu @ 150cs / minti:6. Tube cika inji @ 120cs / minti7. Bututun bututu @ 80cs / minti8

Tambaya .Wana kayan bututun ku (filastik, aluminum, bututu mai haɗe. AbL Tube)

Amsa, bututu kayan zai haifar da hanyar tube wutsiya na tube filler injin, muna bayar da dumama na ciki, mitar m, ultrasonic dumama

Q2, menene bututun ku na bututunku da daidaito

Amsa: bututu cikar buƙatun iyawa zai jagoranci tsarin tsarin dosing

Q3, menene ikon fitarwa

Amsa: nawa kuke so a awa daya. Zai kai yawan yawan cika nozzles, muna bayar da guda biyu uku uku biyar cika nozzles don abokin cinikinmu da fitarwa na iya kaiwa 360 inji na iya kaiwa 360 inji

Q4, menene cikar danko mai ƙarfi?

Amsa: Gwajin abu mai cike da kayan haɗin zai haifar da cika zaɓin tsarin, za mu bayar da kamar tsarin Servo, tsarin ƙananan ƙananan pning,

Q5, menene yawan zafin jiki

Amsa: Bambanci cikawar zazzabi zai buƙaci bambancin kayan aikin duniya (kamar Hopper Hopper, mahautsini, tsarin sarrafa zazzabi, matsayin iska matsi da sauransu

Q6: Menene siffar wutsiya

Amsa: Muna bayar da sifar wutsiya ta musamman, siffofi na yau da kullun don hatimin wutsiya

Q7: Shin injin yana buƙatar CIP mai tsabta tsari

Amsa: Tsarin tsabtace CIP ya ƙunshi tannin tono na acid, tankunan ruwa, mai da hankali da ƙarancin ruwa, tsarin dumbin alka.

Tsarin tsabta Tsarin CIP zai haifar da ƙarin saka hannun jari, ana amfani da shi a kusan dukkanin abinci, abin sha da masana'antar magunguna don filler filler

Kabarin Products

-

E-mail

-

Waya

-

Kai

0086 158002111936

0086 158002111936