Cream tube filling machine is one of the fully tube filling filler for cosmetic field, as it is highly efficient, and at the same time tube sealing and cutting process. there are many shapes on the tube tail to effectively meet the needs of different age groups in the market

The cream tube filling machine usually has a high production speed, and there are different speeds of tube filling machines on the market to meet the selection purposes of different cream manufacturers. It can quickly complete the filling into tube, sealing and cutting tube tails process of creams, oils, gels and other products.

The machine improves the efficiency of the overall production process. The tube sealer can quickly adjust to meet the filling needs of products with different tubes specifications and types. It adopts advanced servo filling technology and fully realizes high-precision metering filling process on the control system to ensure that each product meets the specified filling volume requirements.The fully automatic tube filling machine uses the original imported Swiss Leister heater or the original imported German high-frequency heater to heat the tube tails. In order to make the product more beautiful. Different tube sealing tail shape is used to meet the needs of different terminal groups in different markets.

Right Angle tube sealing tail. Right Angles

Sealing tube tail is the most commonly used tube sealing technology for cosmetic tubes in the market. It is popular with the majority of terminals. The tube filling machine uses the shaping manipulator of the filling and sealing machine to heat the tail of the tube to a specified stability. The machine runs to the next cutting station, and removes the excess tail through the action of the machine to form a right angle shape. In this process, the machine will use heating technology to fuse the two sides of the tube mouth together under high pressure, and quickly cut off the excess tube tails and excess materials to ensure that the seal is firm and beautiful.

Right angle sealing technology is also widely used in the packaging of medicine, food, and daily chemical products. The products of these industries usually require high-precision and high-efficiency filling and sealing processes to ensure product quality and safety. At the same time, right angle sealing also meets the requirements of these industries for product appearance and packaging.

The Rounded Corners design of sealing tube avoids the sharp corners of sealing tube tail, thus producing smooth cut sealing position tails, effectively reducing the potential risk of cuts that operators may suffer when using or handling the product. At the same time, it also protects the end customers, especially children, from the risk of cuts when using tube products. The rounded corners make the hose tail smoother and rounder, improving the overall visual effect and texture of the product. The rounded corner design helps to reduce the risk of damage to the hose during storage and transportation, and also helps to improve the sealing performance of the product.

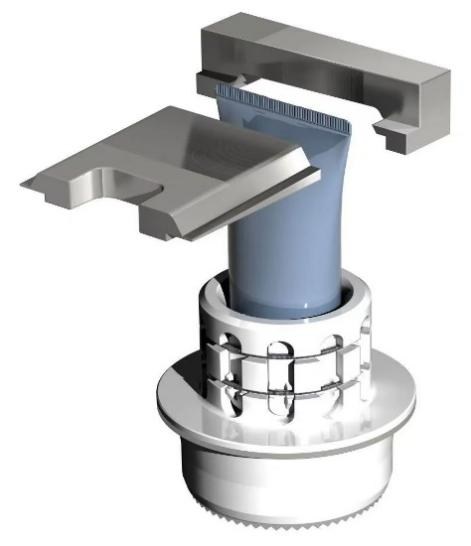

Fully automatic tube filling machine is usually equipped with a special Rounded Corners punching mold assembly, which includes a punch and a die that matches the punch to achieve Rounded Corners shapes. A cutter is provided on the punch, and the punching blade includes a straight section and arc sections on both sides. The die edge of the die matches the shape of the punching blade. Since the mold cutter may wear out after long-term use, causing the cutting surface to become blunt, affecting the quality of the round corner cutter punching, it is necessary to regularly check the wear of the tool and replace it when necessary to ensure the appearance quality of the round corner punched tube tail. The material quality, thickness and accumulation of the tube will also affect the quality of the round corner punching. Therefore, the operator needs to properly handle the material, such as replacing the material with better quality tool steel, and the hardness must be vacuum heat treated to reach 52 degrees to extend the cutter life.

Plastic tube filling and sealing machine Tech parameter

| Model no | NF-60(A B) | NF-80(A B) | GF-120 | LFC4002 | |

| Tube Tail Trimming method | Inner heating | Inner heating or High frequency heating | |||

| Tube material | Plastic ,aluminum tubes .composite ABL laminate tubes | ||||

| Design speed(tube filling per minute) | 60 | 80 | 120 | 280 | |

| Tube holder cavities | 9 |

12 |

36 |

116 |

|

| Tube dia(MM) | φ13-φ50 | ||||

| Tube extend (mm) | 50-210 adjustable | ||||

| Suitable filling product | Toothpaste Viscosity 100,000 - 200,000 (cP) specific gravity is generally between 1.0 - 1.5 | ||||

| Filling capacity (mm) | 5-250ml adjustable | ||||

| Tube capacity | A:6-60ml, B:10-120ml, C:25-250ml, D:50-500ml (Customer made available) | ||||

| Filling accuracy | ≤±1% | ||||

| Hopper capacity: | 40litre |

55litre |

50litre |

70litre |

|

| Air Specification | 0.55-0.65Mpa 50 m3/min | ||||

| heating power | 3Kw | 6kw | 12kw | ||

| Dimension (LXWXH mm) | 2620×1020×1980 |

2720×1020×1980 |

3500x1200x1980 |

4500x1200x1980 |

|

| Net weight (kg) | 800 | 1300 | 2500 | 4500 | |

Semi-circular sealing shape The semi-circular sealing of tube filler and sealer is a sealing form of filling and sealing machine. It means that after the filling of plastic tube filling and sealing machine is completed, the tail of soft tube is sealed in a semi-circular shape under the customized high-hardness mold through the action of the machine. Because this tube sealing shape is not only beautiful and large, but also can effectively prevent cream paste leakage and contamination, ensuring the quality and safety of the product. Semi-circular sealing is suitable for various types of soft tubes and aluminum-plastic tubes, which can meet the packaging needs of different products. This sealing method is increasingly popular with many consumers.

"Aircraft punch hole sealing" in the field of packaging machinery, especially in Tube packaging machinery, usually refers to a special mold tail sealing technology. This technology or equipment is used to seal the tail of packaging containers such as tubes , and form a small hole in the shape of an aircraft window at the tail, and then cut off the excess tail material. Aircraft hole sealing technology uses internal heating technology or high-frequency heating and high-pressure fusion under the pressure of mechanical parts to ensure the tightness of the hose sealing surface. This technology not only improves the reliability of the tube sealing process, but also makes the seal present a smooth and beautiful appearance. Soft tube adopted aircraft punch tube sealing base filling mold can be customized according to customer requirements and product size punch hole, mold disassembly and cleaning are very convenient

Wave tube sealing as a unique packaging design element, the wavy sealing design satisfies the curiosity of young people about the cosmetics packaging market, brings a new visual experience, breaks the singleness of the current traditional straight-line sealing, and this design can quickly attract consumers' attention and increase product differentiation. The wavy sealing has visual appeal, diverse appearance, and is easy to implement, ensuring the flexibility of the production process and effectively shaping the brand image. Plastic sealer makes the wavy sealing an important design element to enhance market competitiveness.

Post time: Nov-13-2024